Assessing Operations Management in Supply Chain and Quality

Executive Summary

The assessment will involve two areas of operations management in the supply chain management and quality management. Both aspects are significant for ultimate success of a business and satisfaction of its customers which leads to customer retention. Under the supply chain management the assessment will look at the general concept of supply chain and supply chain management along with an evaluation of the Lean versus Agile supply chain networks. For business dissertation help, In quality management on the other hand, the assessment delves into what quality means as well as the characteristics of quality, quality management and the GAP model to service quality management. In addition, the assessment will look at practical applications of these concepts and theories at Apple Inc.

Business Management

Among the significant aspects of business management include Supply chain management and Quality management. Fernando and James (2021) define supply chain management as the processes involved in handling the flow of products and services from their raw forms through manufacturing and processing to the delivery of the finished products or services to their end users or consumers. It not only requires an organization to have a comprehensive network of suppliers and distributors but it also requires significant quality management to ensure the preservation of the products’ or services’ integrity on its way to the end user. Quality management highlights organization actions and activities with regards to oversight of processes, activities and tasks within the organization to ensure that the products and services as well as the means adopted in their provision are consistent and of high acceptable standards (CFI, 2020). Quality management helps to maintain a desired level of quality within the organization which in turn enhances customer retention and continued profitability for a company. This report looks to critically evaluate the two business concepts of supply chain management and quality management highlighting their relevance and importance in an organization through a case study analysis of the Apple Inc. a leading global information technology company that specializes in the production of unique electronic gadgets such as the iPhones and Mac as well as internet and software services.

Task 1

Supply Chain Management

A supply chain refers to a network developed between an organization and its suppliers and distributors to produce and distribute a defined product. According to Lutkevich (2020) among the entities involved within a supply chain include the manufacturing or production company, raw material suppliers, warehouses, transport companies, distribution centers and retailers. As such, supply chain management describes the management of all these assets and the processes that occur between them on a continuous basis. CIPS (2020) states that Supply chain management generally involves streamlining the activities involved in the process of procuring raw materials and supplying finished products and services, so as to maximize on customer value and gain a competitive advantage over other companies in the market place.

Not only does it play a critical role in customer satisfaction and retention Supply chain management is also critical in reducing operation costs in procurement activities through enhancing the logistics function and other functions throughout the supply chain. According to CPI (2020) Supply chain management also plays a very significant societal role in ensuring the delivery of the basic necessities humans depend on like food, medicine and other products necessary for survival. According to Fernando and James (2021) a supply chain manger coordinates the logistics of all aspects of a supply chain which generally consist of five parts, a supply chain strategy or plan, the sourcing of raw materials or services, Manufacturing or processing the finished product, delivery and logistics for the products and services as well as a reverse supply chain and return system for defective and unwanted products. Organizations can either adopt the lean or agile supply chain networks within their organization.

Lean vs. Agile supply networks

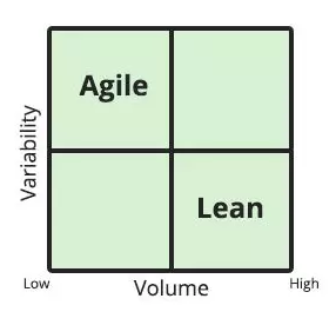

A lean supply chain refers to the traditional supply chain network that is entirely focused on producing high volumes of low cost products to meet a forecasted market. The lean supply chain network majorly focuses on adding value to customers by the reduction of product cost through the economies of scale involved in large productions (Redwood, 2020). The sole purpose of the lean supply chain network is to enhance reliability through intrinsic predictability of the level of demand of a certain product in the market. Production is often planned months or even years in advance in order to identify the lowest possible cost of large volume productions which then allows the company to adequately lower their prices and gain increased sales and revenue. In general the lean supply chain is best for products with low market variability

On the other hand an agile supply chain is mostly focused towards achieving flexibility and receptiveness of the manufactured products and services. According to Lim (2016) an agile supply chain is not entirely dependent on future forecasting of product demand rather it maintains a highly responsive nature to any changes in demand, customer preference and the trends within the industry. It is the best network to adopt when an organization foresees unpredictability within the market. Feron (2021) advances that in an agile supply chain, organizations wait to determine the level of demand of a product before embarking on the production of the exact number of products required to satisfy the demand. However some prediction of the market is still necessary given that the products are partly made ahead of time in order to make finalization on the process faster and more efficient. It is best to adopt an agile supply chain if the market variability of the product is high.

Apple’s Supply Chain

Lu (2020) highlights Apples’ supply chain and handling of inventory as among the major reasons for the company’s consistent success within the digital market. The company’s supply chain strategy has in fact been at the top of Gartner’s supply chain top 25 lists for a better part of the past decade making it the best supply chain in the world. Shram (2018) highlights that Apples supply chain comprises of multiple suppliers of their different components and materials for their final products as well as distribution stores all across the world for supplying finished products to the end users. According to the Australian Institute of Company Directors (2015) Apple further enhances its supply chain by using multiple suppliers for the same component in its supply chain. This not only allows the company to vet and use the most high quality parts and components but also ensures a consistent supply of parts which ensure consistent and timely delivery of products to its consumers. The company also develops products of ostentatious value and in line with any industry upgrades as well as market and consumer changes and demands which make the company’s supply chain an agile supply network.

Quality Management

Quality generally refers to how good a product or service is in comparison to other products and services of the same nature. It ranges from the standards of the product itself to the experience that the products have on consumers and the end users. According to Quain (2019) quality is not just about having organizations offering products and services that exceed the set standards rather it spreads on to the organizations reputation for being able to consistently deliver an above par customer experience that distinguishes it from its competitors. Quality Management as such involves activities directed towards overseeing organizations products and services as well as the different processes involved in their development and production to ensure that they meet and exceed the set acceptable standards (CFI, 2020).

Pereira (2021) advances that a quality product or service is often the ones that meet consumer expectations and are often highly rated in a majority of the eight dimensions of quality. These dimensions include performance, features, reliability, durability, conformance, serviceability, aesthetics and perceived quality. Quality managers or producers can meet consumer expectations of quality by adopting this strategic quality management tool as a framework to analyze the characteristics of their products or services quality Basically they can determine this by asking how adequately the product performs it’s intended purpose, whether or not it possess all the features specified or required for its purpose, how consistently it will perform its purpose, how long it will last compared to its substitutes, how easy it is to maintain and repair, how the product looks as well as its general perception among other customers within the market (Pereira, 2021). If all these questions are positively answered then the product is likely of high quality. The degree of positivity in the answers to the question further indicates how much quality the product or service possesses.

GAP theory of Service Quality

According to Verint (2013), The GAP model of service quality defines a framework adopted by organizations to understand and deliver on customer satisfaction through enhanced quality of services. While the model is predominantly applied within the service industry, it can also be used in the product industry to gauge consumer satisfaction with the quality of products delivered to them. However, the model is widely used by different organizations and businesses in the service industry to understand the various deviations that occur in the process of service delivery.

Verint (2013) asserts that the GAP model creates a path for overall service delivery processes while at the same time identifying the gaps existing between the processes to ensure ultimate effectiveness and efficiency of the service process. Organizations can as such identify the potential gaps between the perceived service and expected service to enhance the ultimate service quality. Often five gaps occur in the process of service delivery and impact the ultimate quality of services provided to customers. These gaps include customer expectation versus management perception, Management perception versus quality specifications, Quality specifications versus service delivery, Service delivery versus external communication and the Actual performance versus the perceived service gap.

Verint (2013) asserts that each gap can be closed through diligent attention to product and service quality management which has an ultimate impact of increased profitability and productivity for the company.

Apple’s Quality Management

According to Fawzy and Olson (2018) for an organization management to be adequately successful and impact productivity, profitability and a competitive advantage, the company must engage in continuously and constantly improving the quality of its products, services and work environment. Apple carries out the quality management through a Total Quality Management strategy, principles and tools. Johnson (2017) advances that TQM is a management strategy that is focused on maximizing the individual capabilities of a company’s employees in order to attain a collective goal. Through adequate people management at Apple encouraging innovation and creativity, Apple can be able to develop unique and high quality products to adequately satisfy the needs of its customers.

The company’s products are considered some of the most high quality and durable products compared to its substitutes and competitors as a result of Total Quality Management. The iPhone for instance significantly fits all the eight dimensions of quality making it a significantly high quality product that is highly competitive in the market. It has all the required features of a Smartphone and more, performs reliably and is highly durable compared to its substitutes. Apple products can also be easily serviced at retail outlets, are aesthetically pleasing and are generally perceived as the ultimate Smartphone currently available within the market. Apple also maintains consistent lines of communication with its customers taking into account their recommendations and feedback in an attempt to close the gaps of service quality to further enhance its overall quality management.

Task 2

Interrelation with another department

While the operations department which involves supply chain management, quality management as well as inventory planning and control includes one of the significant aspects of a business organization that is fundamental to its ultimate success, employees within the organization are also another critical aspect and one that is necessary in all other aspects including the operations department. A company’s supply chain and quality management is inherently dependent on workers for its ultimate success. While some of the activities and tasks in supply chain management and inventory control especially within warehouses have been recently automated thus eliminating the need for individual workers (Jenkins, 2020), the company personnel still retains a significant importance to the operations management department including in handling the machines, overseeing the procurement and delivery of the products, drivers in transport networks, warehouse overall management as well as retailers and sales marketers within other distribution networks.

For large companies, these may involve hundreds or even thousands of employees within the operations department alone who have to be adequately managed, motivated and compensated to ensure their continuous efficiency and productivity. This is where the Human Resource department comes in and interrelates with the operations department. According to CFI (2017) The HR department is responsible for the management of a company’s employees regardless of the department that they work in. While the individuals working in the HR department are sufficiently knowledgeable about the type of employees the organization will need as well as their motivation and remuneration techniques, they may not be sufficiently informed of the type of specialized skills and characteristics necessary for adequate operations in the operations department or any other department such as finance, or information management. As such the operations department and the human resource department have to interrelate, communicate and coordinate in various HR processes such as recruitment and selection of the employees as well as their training and development.

Mangers in the operations department for instance will have to communicate the necessary requirements for specialized talents and personnel required to enhance the companies supply chain efficiency and even contribute in their training and development to ensure that they are adequate in filling any gap in the operations department. The HR department also has to stay in constant communication with the operations department to evaluate employee performance and develop better ways of motivating and enhancing their performance for the ultimate productivity and success of the organization.

Conclusion

The operations department is a key part of any organization and one with a potential for enhancing its competitive advantage. It not only includes the business operations within factories and companies, it also encompasses the procurement of raw materials and supply of finished products as well as the management of product and service qualities to ensure the achievement of the set standards of quality. Through adequate supply chain management, organizations can ensure products and services are developed and reach the end users on time to enhance increased sales and revenue. However in the process of ensuring an adequate supply chain, organizations also have to invest in adequate quality management to enhance the quality of the products and services they sell. Production and delivery of high quality products significantly impact client satisfaction which then promotes customer retention and long-term success of an organization. This makes quality management important even in the development of an organizations reputation. While all these aspects are significant for all businesses, a company’s human resource is perhaps the most critical aspect of the organization and one that ensures the implementation of all its goals and objectives. As such the HR department is also significant in ensuring adequate management of the operations departments’ employees.

Continue your exploration of Asos Environmental Analysis with our related content.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts