Strategic Operations Management at IKEA

Executive summary

IKEA’s global business involves various strategic operations management decisions. These operations management decisions facilitate the organization’s ability to produce functional, affordable and attractive furniture. Consequently, the organization’s primary operations management functions are strategically focused on quality management, supply chain management and cost management. For example, IKEA uses a sales service model instead of attending to its customers through appointed salespeople. It provides the products in a flat packed form to facilitate an easier supply chain – the flat-packed products are easier to handle and carry along. While other companies provide already assembled products at a higher price, IKEA provides dissembled products that can easily be assembled at relatively cheaper prices. IKEA has adopted a global supply chain management system that handles and controls its design, manufacturing and storage. Based on these strategies, operations management is an important management function for an organization and helps it to deliver products and services based on customer needs and demands. . If in case you require business dissertation help, then considering IKEA's operational strategies can provide the best insights into effective practices of operations management.

1.0 Introduction

Jiang et al (2018) defined strategic operations management as the development of an operations system to ensure that a company’s operational resources can meet the market requirements. This report analyzes IKEA’s operations strategy in terms of its key decision areas and how they help the company meet its performance objectives. In doing so, the report will identify how IKEA has organized its pattern of operations decision-making to achieve long-term capabilities by reconciling its market requirements with its operations resources. Therefore, this report will cover various aspects of IKEA’s strategic operations management including capacity management, process management, and lean management.

Founded in Sweden in 1943 and headquartered in the Netherlands, IKEA is a multinational company that designs and sells ready-to-assemble kitchen appliances, furniture, and home appliances. Currently, the company operates in 49 countries and has at least 145 stores globally. Its main products include sofas, beds, bookshelves, bathroom articles, kitchen utensils, tables and other home appliances (Laurin & Fantazy, 2017).

IKEA’s global business involves various strategic operations management decisions including wood and fabric purchase, employee hiring and training, planning and location layout of furniture stores, purchasing raw materials, fabrication materials and other tools. According to Singh et al (2021), these operations management decisions facilitate the organization’s ability to produce functional, affordable and attractive furniture. Consequently, the organization’s primary operations management functions are strategically focused on quality management, supply chain management and cost management (Yang & Shao, 2019).

Looking for further insights on IKEA’s Workforce Management and Strategy? Click here.

The first strategic focus of IKEA’s operations management is on cost organization. Considering that effective operations management must involve the minimization of production cost, IKEA strategically focuses on manufacturing its products at low costs while meeting the product’s requirements for quality, functionality, environmental impact and efficient distribution. For instance, the company strategically uses recycled products in manufacturing, thus incorporating sustainability in its manufacturing processes. Even with the recycled products, IKEA is still known for producing quality and high-value products that exemplify creative designs, affordability and functionality (Yaw, 2018).

IKEA uses a sales service model instead of attending to its customers through appointed salespeople. According to Feng & Lu (2018), the company provides the products in a flat packed form to facilitate an easier supply chain – the flat-packed products are easier to handle and carry along. More importantly, the flat package operations strategy reduces storage, shipping and handling costs – and the reduced costs are passed over to customers through lower prices. While other companies provide already assembled products at a higher price, IKEA provides dissembled products that can easily be assembled at relatively cheaper prices (Lingxiu, 2017).

The other strategic area of focus in IKEA’s operations management is supply chain management. According to Feng & Lu (2018), the company has adopted a global supply chain management system that handles and controls its design, manufacturing and storage. Its supply management operations are categorized into primary, secondary and tertiary supply chain management that involve raw materials, distribution and retail sales respectively (Wu & Peng, 2018). In the primary category, IKEA only uses recycled raw materials to manufacture the products while in the secondary sector, the company uses raw materials from the primary sector to manufacture the products. Lastly, the tertiary sector entails the distribution of manufactured products to suppliers (Laurin & Fantazy, 2017).

IKEA has also strategically focused on quality management. According to Suárez-Ruiz et al (2018), the company’s quality management strategies seek to increase the organization’s productivity and effectiveness while satisfying the customer needs. To achieve this, the company has introduced various quality control tools that are used in various teams and quality cycles – as part of the organization’s culture (Burt et al, 2020). Furthermore, with its quality standards, the company ensures that all the suppliers deliver quality raw materials. Ultimately, with the quality cycles, quality teams and supplier quality standards, the company can have robust process quality control and management. More prominently, the company relies on the quality of a quality staircase model that follows the top management’s commitment to Total Quality Management (TQM). All these focus areas culminate into the company’s strategic operations management that ensures effective process management, lean management and capacity management.

2.0 IKEA’s strategic Process management

As earlier indicated, IKEA’s process analysis can be divided into three major sectors namely primary, secondary and tertiary sectors. In the primary sector, the company depends on its Sweden design location to design all the products while ensuring all the products meet their qualitative, functional and effective distribution requirements (Mishra et al, 2019). In the design process, the company also makes cost considerations – ensuring that the designs will minimize the cost of manufacturing (Sandybayev, 2017). Apart from cost minimization through design, the company also minimizes costs by negotiation with suppliers, verifying the value and conditions of the materials and evaluating the environmental impacts of the materials (Baraldi et al, 2019). This explains why the company has relatively reduced consumption of wood materials – because it majorly uses recycled products as raw materials. At manufacturing (i.e. the secondary sector), the company implements the latest production procedures and advanced analytic capabilities that facilitate a more efficient end-to-end manufacturing process (Lehner et al, 2020).

In the tertiary sector of operations, IKEA implements various strategies to promote a better customer experience – including ensuring that the customers enjoy themselves while in the retail stores. For instance, in every store, the company has a customer relations worker who knows all the IKEA products and can provide any information or advice to customers during their visit (Almaazmi, 2017). For customers visiting with children, they can leave the children at the ballroom for play as they move around to shop. The ballroom is well-maintained and cleaned to ensure the children’s safety and well-being.

3.0 Inventory management strategies

The company has several inventory management strategies that facilitate sits developing and growing of the business. First, the company has maintained a sustainable and long-term relationship with its suppliers, ensuring that it maintains enough suppliers (Yang & Shao, 2019). Moreover, according to Ng (2019), enough suppliers helps IKEA to maintain a lower inventory management cost – because the suppliers provide their services at lower costs.

The company has several inventory management strategies that facilitate sits developing and growing of the business. First, the company has maintained a sustainable and long-term relationship with its suppliers, ensuring that it maintains enough suppliers (Yang & Shao, 2019). Moreover, according to Ng (2019), enough suppliers helps IKEA to maintain a lower inventory management cost – because the suppliers provide their services at lower costs.

The second inventory management strategy adopted by IKEA is the reduced cost per touch inventory strategy, which allows customers to select the products they want to purchase instead of staff members selected for them. According to Vuculescu et al (2021), companies incur a higher cost of inventory management if the number of employees involved in managing the inventory is higher. Therefore, by reducing the number of employees handling the inventory, IKEA reduces its inventory management costs.

The other strategy used by IKEA is the do-it-yourself strategy, which majorly assists the company to reduce packaging and inventory management costs. For instance, the flat packaging used by IKEA makes it easier for customers to transport and assemble for themselves. They also occupy little space and therefore reduces the cost of transportation (Vahlne & Jonsson, 2017).

The company has achieved a significantly unique operations management whereby customers have the flexibility to move around the stores and pick what they want, thereby eliminating the need for sales personnel. According to Ericsson (2018), the idea behind this strategy is to leave the customers to make their own purchase decisions and the staffs’ only role is to guide the customers around the shop. Meanwhile, it is important to note that the company has adopted a process type and layout design that is characterised by large shops designed around a one-way layout feature (Singh et al 2021).

Feng & Lu (2018) argued that this layout design (adopted in older IKEA stores) leads the customers into a natural way of consumption by encouraging them to tour the store and see all the product options as opposed to the normal retail stores that allow customers to only go straight to the sections with the products they intend to purchase. The newer retail stores, however, integrate the use of both aesthetics and glass for various functional reasons. for instance, there are advanced sales services warehouses that motivate the staffs while reducing energy costs and creating a better impression of the products (Lingxiu, 2017).

4.0 Facility and design

The company has adopted a warehouse design that includes both a showroom and a marketplace in one end, allowing for stocks to be kept while still allowing the access of large qualities of stocks within a day (Laurin & Fantazy, 2017). According to Singh et al (2021), most IKEA’S stores are designed to reflect a unified business platform whereby at the end of each warehouse is a cashier and at the same time, damaged furniture that is still in good conditions are sold at a lower price (Lingxiu, 2017).

IKEA’s operations management and logistics help it to communicate and exemplify its environmental policies. In doing so, according to Suárez-Ruiz et al (2018), the smaller stores are in omitted spaces while larger stores are located outside city centers to address the potential issues of traffic and land rates. Regarding facility design, Lingxiu (2017) argues that managers should factor in the element of physical distribution when designing their facilities, so that customers become the destination of the whole marketing channel.

That said, IKEA considers product availability as the main informant to facility design, whereby each marketing channel significantly contributes to the production and distribution of the products. According to Singh et al (2021), IKEA, through the process of physical distribution and facility design, enhances customer time and space by making it a centerpiece of their operations management. The main reason behind this facility design is to effectively control its inventory, transport and warehousing. Furthermore, according to Feng & Lu (2018), this facility design and physical distribution provide an opportunity for the company to plan and control its supply chain through specific strategic decisions. Additionally, IKEA enhances its manufacturing through facility design and physical distribution. in this regard, Suárez-Ruiz et al (2018) wrote that IKEA’s planning, scheduling, and other activities that support products such as transportation, and process storage are done based on the geographic and physical distribution of its operations.

5.0 Capacity management

To effectively manage its operational capacity, IKEA applies its performance management and other logistics perspectives as well as operational management to increase its ability to produce quality products – thereby gaining a comparative advantage. Lingxiu (2017) observed that IKEA’s capacity management is exemplified in its ability to effectively enhance its production and by effective planning that facilitate san overall growth of its business. Through capacity management, IKEA embraces global approaches to supply planning, management and replenishment based on the forecasts of its storage levels (Vuculescu et al, 2021). Through technology, the company has managed to develop a network of operations in at least 202 stores worldwide.

Lingxiu (2017) argued that IKEA’s effective capacity management is evident in how it has managed to hold nearly three million stocks of various products. Furthermore, the company’s reported growth over the past few years shows how efficient it has been in managing its capacity. That said, the company has managed to solve problems of transparency in its supply chain while integrating earlier supply planning with the latest one sot overcome its capacity management challenges.

Technological advancement ha also paved way for IKEA to improve its inventory management strategies. According to Feng & Lu (2018), the company relies heavily on information technology to track its inventory through daily scanning of in or out inventories. Ideally, this strategy involves the use of databases and other relevant software useful in supply chain management. Lingxiu (2017) observed that this approach has helped IKEA keep track of its inventory quantity, costs and location. According to Suárez-Ruiz et al (2018), the use of software in inventory management enables companies to have a clear picture of the quantity sold and allows easier and faster inventory checks.

IKEA allows for simultaneous production and consumption of its products by allowing customers to buy and assemble its furniture at home. However, according to Singh et al (2021), this exposes IKEA to customer influence and evaluation. Furthermore, Lingxiu (2017) argues that IKEA’s process design does not have a clear distinction between the various stages of production and consumption.

IKEA’s strategic approaches to operations management add value to IKEA’s strong market position by enhancing its performance and measurement of such performance. According to Lingxiu (2017) firms that have similar strategic operations management as IKEA benefit from performance remeasurement initiatives that enhance the overall productivity of the company. However, Suárez-Ruiz et al (2018) contend that one of the ways through which IKEA can improve its operations management is through the implementation of leagility in its supply chains. According to Vuculescu et al (2021), leagility refers to the combination of both lean and agility capabilities within a single supply chain.

Therefore, IKEA can improve its inventory through leagility because this can take advantage of the company’s lean capabilities to facilitate its agile performance. Moreover, according to Lingxiu (2017), legeality is a logistic approach that affectively fit with an agile supply chain strategy compared to the lean approach. Approaching its inventory management through the legeality model can optimize the company’s manufacturing asset usability when demand-related variability spikes.

IKEA also uses inventory outscoring as one of the operations strategies it uses to gain a comparative advantage. For instance, according to Suárez-Ruiz et al (2018), the company applies service-parts technology to the in-bound supply side – including vendor managed inventory system. Here, IKEA has virtually no inventory apart from the finished products that it ships to customers. However, the company’s entire inbound supply-side inventory is maintained by its vendors and as a result, the organization’s non-inventory claim is somehow disingenuous.

6.0 Lean Management

But a significantly helpful strategy that the company has adopted is lean management. Ideally, lean management is a strategic approach that seeks to ensure that the company minimizes waste within its manufacturing processes without affecting its productivity (Lingxiu, 2017). A closer look at IKEA’s lean management is applied at various strategic avenues of the organization including total quality management, value stream mapping, production planning and customer relations.

To keep a lean mindset within its customer-busy stress, IKEA implements various safety strategies is to use boldly marked floors to guide customers in the right direction and keep the traffic flowing in an orderly and efficient manner (Lingxiu, 2017). Similarly, according to Feng & Lu (2018), all the warehouses have been marked with a different colour of masking tape to indicate safety hazards and picking points.

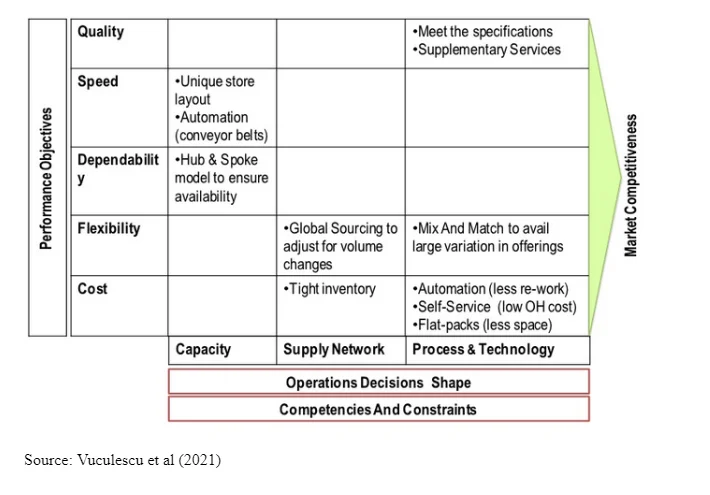

Similarly, IKEA’s lean mindset is exemplified by how the items are marked and processed as customers shop for products. For instance, customers are provided with order forms to mark when they find an item they would like to purchase. In case the item can be picked up in a separate warehouse, this information is indicated on a red ticket. According to Lingxiu (2017), the tickets have all the product details including item description and item number, all of which makes it easier and efficient to trace. The following operations strategy matrix summarises IKEA’s operations strategy:

The companies acquire the quality advantage by doing things right. They manufacture their products based on the specifications that meet the performance standards set by the customer (Lingxiu, 2017). furthermore, the company’s stores are designed in a tidy, clean and unique layout that conforms to its brand identity.

IKEA stores’ unique design layout offers a speed advantage by enabling customers to do things faster. Through the marked floors, customers can easily locate the item. Moreover, the staff maintain low contact with the customers but maintain a friendly and helpful attitude when needed. All the stores have a wide range of products to allow for immediate availability of goods. Customers can check out faster through a steeply ramped conveyor belt that transports items to the cashier.

IKEA’s operations are highly dependable because the shops are open at predictable hours. Furthermore, the company uses a simple reorder system to keep the proportion of goods out of stock low. Furthermore, Suárez-Ruiz et al (2018) observed that IKEA accelerates the arrival of new stock of goods in case they are out of stock or review the reorder quantities in case there is a change in sales pattern. The company also tries to maintain a reasonable customer queuing time, even though one might expect to queue for longer durations during weekdays.

The company operates in a manner that enables it to change faster and respond to customer needs so that they have aa flexibility advantage. For instance, according to Lingxiu (2017), IKEA is flexible enough to introduce new products through its global sourcing strategy, which makes them more flexible to customer demands. Furthermore, according to Lingxiu (2017), the company maintains a creative sourcing strategy that leaves much of the design work to its suppliers and thus enjoys the benefit of the first introduction of new products.

The other strategic approach taken by IKEA in its operations management is to maintain a supply network strategy of at least 46 trading services in at least 32 countries (Lingxiu, 2017). Furthermore, according to Vuculescu et al (2021), the company also has 28 distribution centres across 16 countries that ensure the goods are distributed to all the IKEA stores. Apart from having suppliers from all over the world, the company sources its products from Swedwood Group, a company owned by IKEA.

In summary, operations management is an important management function for an organization and helps it to deliver products and services based on customer needs and demands. This report has highlighted how IKEA uses various operations management strategies to help in the production of cheap, quality, attractive and functional furniture. By strategically focusing on quality management, cost and supply chain management, IKEA has been able to produce low-cost products that are produced through efficient and effective manufacturing systems. The following figure illustrates the company’s operations strategy through an operations strategy matrix.

Recommendations

IKEA managers should factor in the element of physical distribution when designing their facilities, so that customers become the destination of the whole marketing channel

IKEA managers should approach its inventory management through the legeality model can optimize the company’s manufacturing asset usability when demand-related variability spikes.

References

Almaazmi, S.M.M.K., 2017. " Effects of Disruptive-Innovation on industry-level”“IKEA-store” case study (Doctoral dissertation, The British University in Dubai (BUiD)).

Baraldi, E. and Ratajczak-Mrozek, M., 2019. From supplier to center of excellence and beyond: The network position development of a business unit within “IKEA Industry”. Journal of Business Research, 100, pp.1-15.

Burt, S., Dawson, J., Johansson, U. and Hultman, J., 2020. The changing marketing orientation within the business model of an international retailer–IKEA in China over 10 years. The International Review of Retail, Distribution and Consumer Research, pp.1-27.

Ericsson, A., 2018. Organizational Culture and Employee Loyalty: The Case of IKEA.

Feng, Y. and Lu, H., 2018, August. Optimization of Flatbed Loading in Picking Operations of IKEA Warehouse. In 2018 8th International Conference on Logistics, Informatics and Service Sciences (LISS) (pp. 1-6). IEEE.

Goel, R. and Garg, S., 2018. India as a Marketplace: A Case Study of IKEA. Available at SSRN 3282924.

Jiang, Y., Jia, F. and Gong, Y., 2018. IKEA: global sourcing and the sustainable leather initiative. International Food and Agribusiness Management Review, pp.627-639.

Laurin, F. and Fantazy, K., 2017. Sustainable supply chain management: a case study at IKEA. Transnational Corporations Review, 9(4), pp.309-318.

Lehner, M., Mont, O., Mariani, G. and Mundaca, L., 2020. Circular economy in home textiles: Motivations of IKEA consumers in Sweden. Sustainability, 12(12), p.5030.

Mishra, R.K., Raj, A.S. and Karuna, M., 2019. IKEA, Furnishing the Indian Homes: The Challenges of Culture, Competition and Channel. IPE Journal of, p.95.

Ng, I., 2019. IKEA: reducing non-price outlays and maximising demand. The Business & Management Collection.

Sandybayev, A., 2017. Strategic Supply Chain Management Implementation: Case Study of IKEA. Noble International Journal of Business and Management Research, 1(1), pp.5-9.

Singh, P., Rao, K.S., Xuan, L., Kee, D.M.H., Min, F.J., Xuan, T.Y., Ing, T.S., Malhotra, K. and Pandey, R., 2021. Key Determinants of International Retail Success: A Case of IKEA Retail. International journal of Tourism and hospitality in Asia Pasific (IJTHAP), 4(1), pp.18-33.

Singh, P., Rao, K.S., Xuan, L., Kee, D.M.H., Min, F.J., Xuan, T.Y., Ing, T.S., Malhotra, K. and Pandey, R., 2021. Key Determinants of International Retail Success: A Case of IKEA Retail. International journal of Tourism and hospitality in Asia Pasific (IJTHAP), 4(1), pp.18-33.

Suárez-Ruiz, F., Zhou, X. and Pham, Q.C., 2018. Can robots assemble an IKEA chair?. Science Robotics, 3(17), p.eaat6385.

Vahlne, J.E. and Jonsson, A., 2017. Ambidexterity as a dynamic capability in the globalization of the multinational business enterprise (MBE): Case studies of AB Volvo and IKEA. International Business Review, 26(1), pp.57-70.

Vuculescu, O., Beretta, M. and Bergenholtz, C., 2021. The IKEA effect in collective problem‐solving: When individuals prioritize their own solutions. Creativity and Innovation Management, 30(1), pp.116-128.

Wu, Q. and Peng, J., 2018, November. Enlightenment of IKEA’s Multinational Operations to Chinese Enterprises. In 2018 5th International Conference on Education, Management, Arts, Economics and Social Science (ICEMAESS 2018) (pp. 885-890). Atlantis Press.

Yang, L. and Shao, N., 2019. Sustainability Strategies in IKEA with the focus on Production and Suppliers.

Yang, L. and Shao, N., 2019. Sustainability Strategies in IKEA with the focus on Production and Suppliers.

Yaw, W.K., 2018. Effects of Globalization on Asian International Retailing: Case of IKEA. Asian Research Journal of Business Management, 5(4).

Looking for further insights on Strategic operations and outsourcing? Click here.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts