Sustainability and Ethics in the Fashion Business Cycle Nike

Introduction

Brand sustainability and ethical principles are mandatory to follow in order to gain high competitive advantage in near future by running the business activities efficiently. The ethical practices as well as managing social and environmental sustainability will provide a scope to the multinational corporations to manage their operations ethically and create values for all the stakeholders (Ceccagno, 2017). The aim of the report is to analyse the Sustainability and ethics within the fashion business cycle and in this study, the famous organisation Nike will be evaluated for understanding the practice of the brand in maintaining global sustainability. Through critical analysis of the Fabric and component sourcing methods of the brand and manufacturing methods, it is possible to gain in depth understanding about the organisational practices to maintain product life cycle and make the brand successful in near future. For the most comprehensive insights into sustainable business practices, seeking business dissertation help can offer the most valuable guidance.

Organisational background

Nike is a famous American multinational corporation which is renowned for designing, manufacturing quality products, development, and maintaining marketing and sales of the footwear, apparel, equipment and accessories for the customers, mainly the athletes. The organisation is the world’s largest supplier of the athletic shoes and apparel with unique design and services. There are more than 76,700 people empowered worldwide. Additionally, it manufactures quality products and become successful to generate revenue about US$37.4 billion in its fiscal year 2020. It mainly runs their business across the worldwide through the apparel, accessories and sports equipment industries.

Figure 1: Brand logo

The products of the company are Athletic & recreational products Athletic footwear & apparel, and other sport equipment. The mission of the brand is to do everything possible to expand the human potential through making quality products more sustainably as well as creating groundbreaking sport innovations and building creative and diverse global team (Nike, 2020a). Nike exists to bring inspiration and innovation to every athlete with the aim of the brand that is to move the world forward by the power of sport, creaking the barriers and community to change the game for all. Hence, innovations and latest products design further give confidence and influence the athletes to perform better for achieving future success (Nike, 2020b).

Fabric and component sourcing methods of Nike

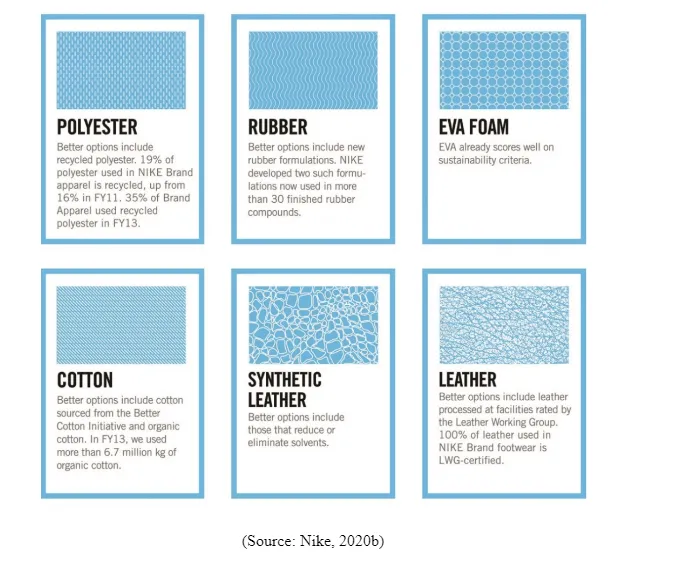

The component sourcing methods and fabric of the brand is important to be analysed in order to evaluate the corporate social responsibility, so that there would be less negative impacts on society and environment. The organisation Nike is efficient to choose their fabrics and raw materials to make sustainable products. The major fabrics utilised by the brand Nike are such as rubber, cotton, polyester, synthetic leather, Eva foam, and leather, each of which requires enormous amounts of resources (e.g., water) and energy (emitting greenhouse gases) to produce (Nike, 2020b).

Figure 2: Fabrics and raw materials utilised in Nike

One of the biggest steps of the journey of Nike is to choose the materials in order to make zero carbon and zero waste solution in the organisation and it further account for more than 70% of the product's footprint in the brand. Nike tries to significantly reduce our emissions by reusing existing plastics, yarns and textiles. Nike Fly knit is a light weight fabric precision-engineered with an average of 60% less waste than the traditional footwear manufacturing, where each shoe upper made from Fly knit contains 6–7 plastic bottles (Nike, 2020b).

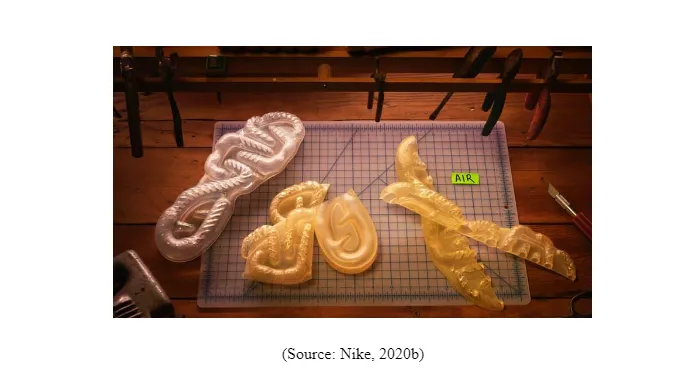

Figure 3: Nike Fly leather

Additionally, Nike Fly leather is also effective which feels looks and smells like natural leather, and it is made by bonding at least 50% of the recycled leather fibres with synthetic fibres by using a water-powered process. It is effective way to maintain sustainability where utilising Nike Fly leather makes less waste and lower impacts on the climate change that the full grain leather (Nike, 2020c).

Moreover, Nike Air soles are mainly composed of 50% recycled manufacturing waste which is beneficial for the brand. As of 2020, all of Nike's Air MI facilities in North America are powered by 100% renewable wind energy which is also another sustainable solution. Reusing more than 90% of the waste from the materials can be possible under the Air soles to make new, innovative cushioning system to develop the best possible products in the market by securing future sustainable development (Nike, 2020d).

Figure 4: Nike Air soles

Nike arranges most of the cotton from the international suppliers in India, turkey, China and United States. Nike develops the planning of having at leasing 10% of organic cotton in all of their appeal. The designer apparel is produced mostly from the cotton fabric, polyester and others. Nike also helped to recycle about 82 million plastic water bottles for making polyester out of and in 2010 was 100% recycled polyester each using eight plastic bottles. The brand also utilises environmental friendly rubber and in this regard altered rubber is produced by incorporating more benign accelerators and vegetable oils and it is imported from the export countries Thailand, Indonesia and Malaysia (Curtis & Hansson, 2019). The main producers of Eva Foam are located in China, where Eva foam is the main component of the manufacturing unit of Nike. The brand additionally utilises the synthetic leather from the countries China and Taiwan as these are the leading international supplier of synthetic leather worldwide. Hence, the company has strong suppliers and distributors to run the business and maintain the stock of raw materials from other export countries worldwide. The strategies of sourcing the materials and maintaining tis sustainability are effective to sustain in the competitive fashion industry worldwide (Nike, 2020e).

Critically evaluating the manufacturing methods of the brand

As per the manufacturing process of Nike, the organisation Nike outsources the internal manufacturing to the famous third parties outside the USA, which mainly utilise the latest machines that consume vast amounts of energy such as again, emitting greenhouse gases as well as produce waste in the form of excess fabrics. The brand has risen to the number one athletic sportswear company across the globe and it maintains 533 factories to produce the best quality products. There factories are located across 41 countries and there are more than 1.1 million workers who are efficient to handle the whole manufacturing process, where Adidas the main competitor of Nike has 500 independent factories. Most of the factories of Nike are situated in Asia including Pakistan, India, China, Indonesia, Philippines, Thailand, Taiwan, Vietnam, and Malaysia (Childs & Jin, 2018). And the major reasons of opening the factories in Asia are such as low cost of products, low wage rate and huge population. For distributing the products, Nike has strong supply chain and distribution network worldwide to run their operations in a systematic manner. In 2019, Nike’s footwear components were majorly supplied by more than 112 different factories across 12 countries, where there is no factory accounting for more than 9% of branded footwear. The finished goods of Nike are taken from the factories to Nike-owned distribution centres and the products are shipped to the end consumers all around the globe, that further raising energy consumption and increasing the Nike’s carbon footprint. The freight services are effective to distribute the final products safely to the end customers (Nike, 2020d).

Figure 5: Close loop of Nike

As per the close loop eco system of Nike, it has been that, the products are sourced sustainably and the good are manufactured under effective supervisions and latest technology. The design and innovative process are effective to maintain the product life cycle and retain more customers for the best quality sportswear products and services, where Most Adidas shoes are made by cold cement construction (Almiya et al., 2020). The company introduced Nike Air technology, where Nike Air technology mainly consists of pressurized air inside a tough yet flexible bag and it further provides more spring without compromising the structure. The Air Max 270 is the first air shoe manufactured specifically for the lifestyle wear. The smooth lines and cushioned ride have won over the likes of Kevin Durant, setting the bar high for future innovations (Nike, 2020e). Additionally, aiming 100% organic cotton utilisation and reducing the greenhouse gas emissions to reduce the environmental impacts further influence the brand to renovate their activities. Additionally, Nike is a successful company with more than 600 manufacturing partners outside the US. As per the ethical practice, Nike is an extensive brand reach with innovation and technical creativity to make the best products for the athletes. Both the fashionable clothing and shoes attract the buyers and in this regard Nike also becomes successful to maintain their corporate social responsibility across the international markets. The journey towards zero waste and zero carbon will influence the brand to make better future. As per the analysis, apparel labelled "sustainable materials" is made from almost 50% recycled content in the company, and on the other hand, the shoes with the company label are made from approximately 20% recycled content by weight (Nike, 2020f).

Assessing the impact of the product use and end of life phase of the product life cycle at Nike

There are several social and environmental impacts after the product use which raises unethical practices in the country. Nike focuses on creating zero carbon and zero waste organisations by developing their recycle process in order to retain the old products. In order to maintain the product life cycle and end of life phase, the strategies are manufacturing, materiel extraction, sustainable packaging and strong transportation and freight system, use and end of life. Nike’s “Reuse a Shoe” Program is effective to support the customers to contribute in the brand recycling process, so that it would be possible to minimise the environmental impacts (Jiang, 2019). Through Nike’s “Reuse a Shoe” Program, there are more than 30 million pairs of shoes that have been recycled. As per the sustainability report of Nike, 71% products are developed through recycled materials which is effective for Nike to reduce the negative environmental footprint in near future. In order to maintain close loop and eco system of the brand, Nike also asks the customers to recycle their garments as it is made from polyester and cotton. Most of Nike’s products are now manufactured from the recycled waste and on the closed-loop front, the brand Nike further diverted 92% of its trash from landfill to non-energy recovery incinerators in 2015, and it focuses on making this 100% by 2025 in order to ensure zero waste and zero carbon. The Nike Fly knit shoe debuted in the year of 2012 and revolutionised waste minimisation in footwear production by utilising knitted together, where it utilises single fibres, instead of multiple, separate, traditional fabrics and it further influence the brand to increase waste management process and recall the customers for collecting the used shoes and garments. The garments are also recycled for manufacturing process where the company mainly focuses on utilising organic cotton and polyester for their garment production (Gardetti & Torres, 2017). Though the brand is efficient to ensure waste management, there are still environmental impacts due to energy use and water usage which increases negative environmental footprint (Nike, 2020f).

Conclusion

Nike focuses on sourcing 100% of its cotton from recycled, certified-organic, or better cotton sources, in order to produce sustainable garment products for the customers across the globe. Additionally, by 2025, it plans to utilise 100% renewable energy including geothermal, solar, and wind at company owned facilities. As per the analysis, the organisation is successful to develop sustainable manufacturing unit and also create strong supply chain and distribution network across the international countries. The major fabrics and raw materials utilised by the organisation are cotton, polyester rubber, Eva foam, synthetic leather and leather, each of which requires enormous amounts of resources energy and water. It is hereby important for Nike to develop further planning for making the brand 100% sustainable.

Recommendations

Nike must implement the solar panel at the roof top of the factories so that it can reduce the energy usage and increase the use of renewable resources for the production and manufacturing units of shoes and garments.

The company needs to invest in the electric cars for distributing their final products across the international countries in a sustainable way. The use of electric cars further helps the brand to reduce greenhouse gas emission and make sustainable solution towards zero carbon.

Nike focuses son sourcing 100% organic cotton and also adopts new recycling techniques in the factories for making the brand sustainable and gaining high competitive advantage.

References

Almiya, M. S., Kee, D. M. H., Haron, M. Z. B., Nasharudin, M. I. B., Nasruddin, M. M. B. M., & Johari, M. E. W. B. M. (2020). Consumption of Plastic and Sustainability Efforts of Nike towards Green Environment. International Journal of Applied Business and International Management, 5(1), 60-73.

Ceccagno, A. (2017). City Making and Global Labor Regimes: Chinese Immigrants and Italy's Fast Fashion Industry. Berlin: Springer.

Childs, M., & Jin, B. (2018). Nike: An Innovation Journey. In Product Innovation in the Global Fashion Industry (pp. 79-111). Palgrave Pivot, New York.

Curtis, A., & Hansson, A. (2019). Examining the Viability of Corporate Recycling Initiatives and Their Overall Environmental Impact: The Case of Nike Grind and the Reuse-A-Shoe Program. Case Studies in the Environment, 3(1), 1-7.

Gardetti, M. A., & Torres, A. L. (Eds.). (2017). Sustainability in fashion and textiles: values, design, production and consumption. London: Routledge.

Jiang, W. (2019). Sustainable Development of Supply Chain in Footwear Industry–Take Nike as the Case. Asian Business Research, 4(3), 86.

Nike, (2020a). About us. Retrieved from: https://about.nike.com/

Nike, (2020b). Purpose. Retrieved from: https://purpose.nike.com/

Nike, (2020c). Materials. Retrieved from: https://www.nike.com/in/sustainability/materials

Nike, (2020d). Air manufacturing innovation. Retrieved from: https://about.nike.com/pages/airmi-home

Nike, (2020e). Sustainability. Retrieved from: https://www.nike.com/in/sustainability

Nike, (2020f). NIKE Annual Report 2020. Retrieved from: https://annualreport.stocklight.com/NYSE/NKE/201047033.pdf

Looking for further insights on Sustainability and Biodiversity in Business? Click here.

What Makes Us Unique

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts