Volkswagen's Supply Chain and Strategic Partnerships in the Global Market

Introduction

Every organization that performs in the market has certain basic goals of creating value in the consumers and enlarging the business with the help of strategic partnership. There are various organizations that perform in the global market. Each organization has its own supply chain system to support the business. The supply chain helps the organizations to serve the customer and ensure that the organization can successfully create and maintain value to the customers as well as to the shareholders of the company (Abdel-Basst, Mohamed & Elhoseny, 2020). Similarly, a company in order to sustain itself in the global market creates strategic partnerships with various organizations so that it can successfully run the business and create value in every sphere of the market (Gaim, Clegg, & Cunha, 2019). Here the organization Volkswagen has been chosen as the organization has a prominent supply chain that helps the company live up to the goal of sustainability in the car manufacturing process. If you are searching for business dissertation help, understanding the intricate details of supply chain management and strategic partnerships can enhance your whole research and analysis.

PurposeThe purpose of the study is to ensure that the supply chain and logistics issues can be identified and the relation of the same with value creation and building up a strategic partnership can be evaluated. The automobile sector depends on the supply chain largely for the operation and the mentioned company has faced certain issues in terms of value creation which are related to the logistic operations of the company. Hence, the purpose of the study can be justified through the study.

Rationale

Rationale

The main reason or objective behind the study is to critically analyze and evaluate how strategic partnership and value creation are interlinked to the supply chain and how an organization at the global level can deal with such issues on the large scale. The research is conducted on the company Volkswagen in order to analyse the strategic partnership and its impacts on running the business efficiently. Volkswagen is a German motor vehicle manufacturing organisation and it is successful to gain high market share across the international markets. Through this research, it is possible to identify the strategic partnership and value proposition strategy so that it would be possible for Volkswagen to maximise their performance in the recent pandemic situation.

Choosing the organization Volkswagen would be beneficial for this study to conduct in-depth analysis about the value proposition, value chain model and strategic analysis for recommending suitable suggestions for strategic partnership and value creation for the stakeholders.

Discussion

Strategic alliance or strategic partnerships depicts a process of connecting and collaborating with various business partners in order to ensure the performance of the business more effectively (Clemente, & Gabbioneta, 2017). An organization can perform well in the market; however, the strategic partnership helps in creating better sustenance in the market (Clemente, & Gabbioneta, 2017). The idea Strategic alliance can be done in different ways, there are mainly three different theories such as Transaction of Cost Theory, the Resource-Based Theory, and the Knowledge-Based Theory. These theories point out the way an organization shall connect with the business partners, or choose to operate within the market. The strategic alliances also help out an organization to strengthen its supply network through which it can operate the business in a local or in the global market. Hence, the strategic partnership is essential to be chosen so that an organization Volkswagen can get success from the same.

According to Russo, & Cesarani, (2017), the Transaction cost specifies the costs or expenses that an organization is required to bear to perform in the global market, or the negotiation and bargaining that includes while making efforts and accepting orders or providing or delivering the product are the transaction costs. Therefore, organizations often need to rely on a specific supplier or partner who works as the third party that can manage the supply network of the organization to cut down the bargaining costs and negotiation. Thus, it is beneficial for Volkswagen to develop partnership or alliances that are effective to minimize the transaction cost or the fluctuation in the same are known as the Transaction Cost Theory of partnership or alliance. However, there are also some pros as well as cons to the theory and its practices. Such as, often the alliance can even minimize the scope of having access to a cheaper supplier network which can also provide similar quality but at a lower transaction price. Thus, alliances with other company can both minimize the cost and also minimize the scope of accessing a supply network which can cost lower than the existing one.

As mentioned by Ferreira, Mueller, & Papa, (2018), resources are essential for an organization to sustain and compete in the market. Each and every organization that performs in the market requires resources that are essential to ensure that the company's production is in process and the organization can gain a competitive advantage. However, it is not always possible for an organization to avail the best quality resources at the right time to stay ahead in the market, therefore, in order to ensure that the resources are timely delivered and of the right quality, an organization often get engaged with another organization or a business partner or alliance that can deliver the resources as per the requirement of the company. Resources and the capacity of Volkswagen would be effective determine the successful performance of a company in the competitive market, where each and every competitor is availing the best resources to stay afloat in the competition.

Knowledge-Based Theory

Apart from cost-effective and potential resources, an organization is also required to have access to certain knowledge and channelize them to ensure they are practiced. In order to improve business mechanisms or widening the ranges of operations or in order to operate in a new market, an organization must have adequate knowledge of the same so that they can perform successfully (Fathollahi-Fard, Hajiaghaei-Keshteli & Mirjalili, 2018). Thus, Volkswagen is a famous company in the automobile sector and it is planning to launch a new product or new range, hence, it must have knowledge about the working mechanisms and production knowledge, and in order to do the same, the company will need an expert to be partnered with so that the knowledge can be shared adequately. Similarly, if penetrating a new market, the organization Volkswagen must partner with an organization that is aware of the new market's behavior and strengths, which is again a knowledge that is the base of the alliance or partnership (Fathollahi-Fard, Hajiaghaei-Keshteli & Mirjalili, 2018).

Critically discuss the supply chain network and its issue in Volkswagen

According to Ćurovac, Persia, & Campagna (2018), the supply chain network of an organization depicts the network through which the organization is getting supplied the raw materials and part material to manufacture the entire well and send the finished product into the market. It is a linear recurring process that ensures the unhindered pace of an organization's production. Volkswagen is a German automobile organization that is widely available in Europe and also highly appreciated in the global market because of the engineering and quality. The company has a total of 125 production units spread across the world where the raw materials are supplied, cars manufactured and then sent to the markets of the same region or in the neighbouring regions (Fathollahi-Fard, Hajiaghaei-Keshteli & Mirjalili, 2018). Amongst all 125 manufacturing units, the company has more than 20 in Europe. However, all these manufacturing units run successfully because of the supply chain network of the company (Fathollahi-Fard, Hajiaghaei-Keshteli & Mirjalili, 2018).

On the other hand, it has been stated by Yu, & Cruz (2019), the manufacturing defects and issues can be identified in many Volkswagen cars, and the defects are also caused by the lack of maintenance in the supply chain network at every manufacturing unit. In recent years various challenges have been faced by the organization in its supply chain system due to overprice from the suppliers or disputed materials required for the sustainable programs (Govindan, Fattahi & Keyvanshokooh, 2017). The recent Coronavirus outbreak throughout the world has increased the cost of the part materials of the company. The suppliers from where the organization has been receiving the part materials like engine materials, car parts, tire, etc. have increased their costs due to the supplied medium charges increase, inability to access the bans, and restrictions in cross-border transportation. Thus the company is being affected and the production costs have also increased (Jacobs et al., 2017). Similarly, in many cases and in many units the materials that are being supplied are not up to the mark as the availability of the resources has shrunk (Jacobs et al., 2017).

Also as opined by Siano, et al., (2017), the company has faced the emission of Carbon scandal which was also caused due to the ill-managed supply chain of the company. It has been identified that in 2010 the company has claimed to introduce a range of cars in the market that has low carbon emission in the market, however, it has been identified later by the United States Environmental Protection Agency that the carbon and Nitrogen Dioxide emission rate of the stated cars are much higher than the other cars. The scandal broke out in 2015 (Mačaitytė & Virbašiūtė, 2019). This particular incident highlights the poor management of the company in managing its supply chain network as the diesel control mechanisms have been supplied to the company from their suppliers. Therefore, the anti-pollution system has been faulty and does not provide the facility that it claims.

However, it is not justified to discuss the inability and issues of the supply chain of the company, but it is also essential to understand that the company Volkswagen has been performing in the market since 1937 and considered to be one of the most reliable car manufacturing and selling company in the world because of the great management of the supply chain that has supported the organization to expand it's business and opening more than 125 manufacturing units in the world. Through managing global supply chain network, developing electronics cars for maintaining sustainability as well as creating values for the suppliers by providing high return on their investment, it is possible for the company Volkswagen to manage their strong supply chain.

Understanding the value proposition of Volkswagen in the global market

Every organization that performs in the market has the idea of creating certain values and delivering the products by creating a valuable impact on the customers of the same. Here, the value proposition framework can be used in order to analyze the position and performance of Volkswagen in terms of creating value amongst its customers (Payne, Frow & Eggert, 2017). The value proposition model helps in analyzing whether an organization is positioning its products and services to meet the customer's requirement or not. In the case of Volkswagen, it is essential to understand how the organization is meeting and delivering the needs of the customers, as there is huge market competition and the value proposition of a product or a company provides the competitive advantage to the same.

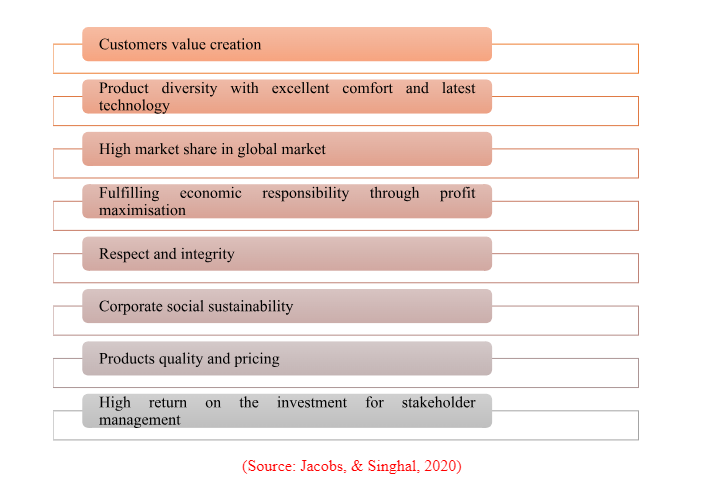

According to Jacobs, & Singhal, (2020), an organization like Volkswagen has a great market base and the customer segment is also versatile. This customer segment on the other hand is only limited to the higher and medium earning people of the world which highlights that the values are mainly created for a certain section of people. However, it can be seen that, the organization Volkswagen has focused on the sustainable practice of production. Sustainable practice has been started with the goal of minimizing global warming and environmental pollution measures. In the current global market, it has been identified that the global warming issue has emerged to be the most important concern, similarly, overexploitation of the natural resources has also caused major concern to the global market, therefore, coming up with a measure that can minimize the concern and also deliver a comfortable driving experience has been the goal of the company. The company has understood the importance of sustainability measures and therefore, has partnered with One. Konzern Business Platform under which there are 11 other car manufacturers included (Painter, & Martins, 2017). Thus, it can be said that the organization has given adequate value to the concept of sustainability along with quality and pricing. The customer can gain a sustainable relaxing and quality driving experience through the Volkswagen cars.

The company has also ensured from the suppliers that the customers can get a safe driving experience in the Volkswagen cars (Painter, & Martins, 2017). The cars are well tested in the safety measures, such as break and stability of the cars, airbags, child safety, crumple zone, tire pressure, and flat tire sensor system, Euro NCAP, driver alert, locking, and security system, etc. are some of the pain areas of the customers which are considered as a major priority of the company and that helps the same to create value in their consumers (Painter, & Martins, 2017).

Analyzing the Volkswagen value chain through value chain model

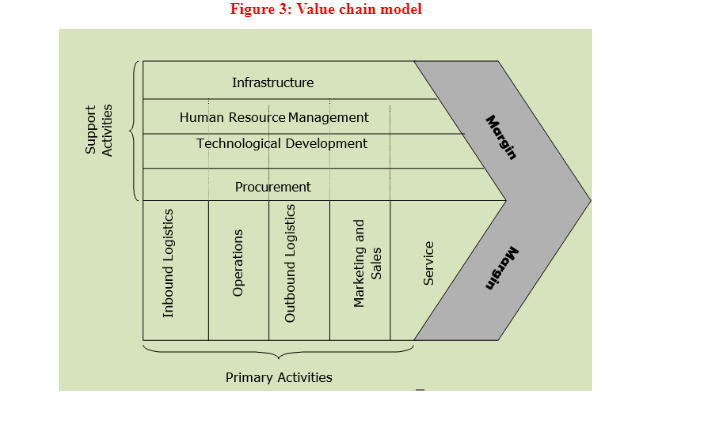

According to Koval, et al, (2019) value chain model or canvas is a framework through which an organization and its business operations and functions can be analyzed or understood. When an organization performs in a market there are various things and areas that work together to make the overall performance of the company successful, each of the areas is essential for the growth and success of an organization. Therefore, the value chain model helps out in understanding the values that are vested in the operations of an organization (Li, et al.,2018). There are certain primary activities or operations which are inevitable, these functions are Inbound Logistics, Outbound Logistics, Operations, Marketing and Sales, and lastly, Services. Apart from the primary functions, there are also certain support activities such as Procurement, Human resources, Infrastructure, and Technological development.

In order to manage the worldwide procurement of sustainable and reliable quality materials, the organization has created a common platform called ONE. Konzern where various big brands and also the suppliers are connected directly. Also, in order to manage the inbound logistics, the organization uses the Naves hubs, which are basically the inventory of the organization, Even Volkswagen ensures that the supplied goods are delivered within the facilities and checked so that no wrongdoing can be performed (Painter, & Martins, 2017).

Volkswagen manufacturing units have different operational departments that manage different works, such as the Wolfsburg facility prepare and operate the pressing works, after that the metal sheets are sent to the body part building process. This part is done by applying the models and designs how the entire body of a car would look like, what it will contain, and everything (Whittall, et al. 2017). After the body is prepared, the painting of the car is done and lastly, the interior, as well as the exterior parts, are assembled together to make the car able to be checked for security, safety, and trial measures and then sent to the markets (Free, & Hecimovic, 2020).

Auto Port control is the official partner of the company that manages the outbound logistics, delivering the finished car in the global market is done through the same source. The company sells or distributes the cars in more than 150 markets through road and waterways. The main mediums are lorries and sea-vessels. Thus, it can be stated that the company provides adequate attention to the outbound logistic programs (Painter, & Martins, 2017).

The company has their global marketing communication facility that operates and undertakes the marketing practices. The company uses new and advanced technologies to operate the marketing and sales of the company (Welch, 2019). Also for the services the organization arranges Proactive Maintenance Management programs, workshops and the company also the sole authority that takes the charge of the parts and everything therefore, they provide services as per the guideline of the company that is convenient and customer friendly.

Traffic Jam Pilot, Autonomous Parking, etc. are some of the new technologies that have been introduced by the organization. The company also manages its future procurements through Future Automotive Supply Tracks (Free, & Hecimovic, 2020). The human resource recruits employees and manages the employee section with a general system of shortlisting and employee rule books. There is partnership working practice at the organisation which is beneficial for managing the inbound and outbound logistics system of Volkswagen. The company Volkswagen has its infrastructure eco-friendly that manages air pollution, reduces carbon emission, waste management, etc measures with advanced systems.

Traffic Jam Pilot, Autonomous Parking, etc. are some of the new technologies that have been introduced by the organization. The company also manages its future procurements through Future Automotive Supply Tracks (Free, & Hecimovic, 2020). The human resource recruits employees and manages the employee section with a general system of shortlisting and employee rule books. There is partnership working practice at the organisation which is beneficial for managing the inbound and outbound logistics system of Volkswagen. The company Volkswagen has its infrastructure eco-friendly that manages air pollution, reduces carbon emission, waste management, etc measures with advanced systems.

Evaluate the value chain and supply network of Volkswagen in the COVID affected the market

The value chain and the supply network of the company have already been discussed in the previous sections of the paper, but how the system does has been changed or the effectiveness of the same has changed due to the COVID affected market has not been discussed yet. It has been identified that the COVID 19 outbreak has affected the entire world and the market performance at large. The global market has seen a major setback after the outbreak of the Pandemic (Sodhi, & Tang, 2020). Many parts of the world have minimized the free transportation across the borders, the free movements of people and goods have been closed and elated which has changed the market demand, productions, costing of production and also the customers preferences. During the early stages of the pandemic outbreak, many governments have called for lockdown that has forced the company's manufacturing unit to shut down even though the managerial areas have been working from their home (Free, & Hecimovic, 2020). Thus, the overall production of Volkswagen has seen stagnation, and that directly affected the outbound logistics. Similarly, due to stagnation in the market, the company has also failed to receive the inbound logistics on time or the suppliers have increased the pricing which has directly increased the overall costing of the company. On the other hand, more than 400 million people have lost their job which has minimized the market demand. Thus, the COVID affected market has changed the entire dynamics of the supply network and value chain that the company has been creating in the market for a long.in this regard, the strategic partnership with Microsoft is effective for Volkswagen to run their business and develop software-driven mobility provider in this pandemic situation (Free, & Hecimovic, 2020). Volkswagen Automotive Cloud becomes a unique solution for the customers to support them with high quality products and enhancing market communication through cloud based system.

Conclusion

After analyzing the entire paper, it can be said that Volkswagen, being one of the leading automotive manufacturers and sellers, has certain issues with its supply chain and value chain processing. The company has faced a few major issues in recent years related to the quality or the product-related areas that have caused the loss of goodwill and brand equity. However, it can not be denied that the organization has also undertaken a few decisions related to the supply chain in recent years such as ONE.KBP or Logistics partnership etc. This initiative has helped out the organization to retain the market value and create a successful customer value. The strategic alliances of the company have also played a crucial role in the ups and downs that have been faced by the company.

Recommendations

Recommendations

Here a few recommendations made for the better future performance of the company Volkswagen in the future.

The company needs to be more strict in terms of monitoring and evaluating the inbound logistics of the company so that no issues can be raised related to the same area as the products that are sold determines the future of the company.

Similarly, growing the supplier units near the manufacturing units and opening more manufacturing units near the market areas are essential for the organization to overcome supply-related issues that are raised during COVID or any other times. With strategic partnership with Microsoft, the brand should expand their cloud computing system and provide online services to the customers.

Through strategic partnership, the company must expand their inbound and outbound logistics. The company vision is together – Strategy 2025, where the organization focuses on developing strategic partnership for brand expansion and gaining high competitive advantage. In this regard, Volkswagen should develop strategic partnership with Amazon Web Services (AWS) and accept the integration partner Siemens for network management and cloud management system.

Reference List

Abdel-Basst, M., Mohamed, R., & Elhoseny, M. (2020). A novel framework to evaluate innovation value proposition for smart product–service systems. Environmental Technology & Innovation, 20, 101036.

Bachmann, R., Ehrlich, G., & Ruzic, D. (2017). Firms and collective reputation: The Volkswagen emission scandal as a case study (No. 6805). CESifo Working Paper.

Canzaniello, A., Hartmann, E., & Fifka, M. S. (2017). Intra-industry strategic alliances for managing sustainability-related supplier risks. International Journal of Physical Distribution & Logistics Management.

Chossière, G. P., Malina, R., Ashok, A., Dedoussi, I. C., Eastham, S. D., Speth, R. L., & Barrett, S. R. (2017). Public health impacts of excess NOx emissions from Volkswagen diesel passenger vehicles in Germany. Environmental Research Letters, 12(3), 034014.

Clemente, M., & Gabbioneta, C. (2017). How does the media frame corporate scandals? The case of German newspapers and the Volkswagen diesel scandal. Journal of Management Inquiry, 26(3), 287-302.

Ćurovac, A., Persia, L., & Campagna, A (2018) Sustainable Supply Chain Management in Automotive Industry, obstacles and challenges: The case of Volkswagen Sarajevo.

Fathollahi-Fard, A. M., Hajiaghaei-Keshteli, M., & Mirjalili, S. (2018). Multi-objective stochastic closed-loop supply chain network design with social considerations. Applied Soft Computing, 71, 505-525.

Ferreira, J., Mueller, J., & Papa, A. (2018). Strategic knowledge management: theory, practice and future challenges. Journal of knowledge management.

Free, C., & Hecimovic, A. (2020). Global supply chains after COVID-19: the end of the road for neoliberal globalisation?. Accounting, Auditing & Accountability Journal.

Gaim, M., Clegg, S., & Cunha, M. P. E. (2019). Managing Impressions Rather Than Emissions: Volkswagen and the false mastery of paradox. Organization Studies, 0170840619891199.

Govindan, K., Fattahi, M., & Keyvanshokooh, E. (2017). Supply chain network design under uncertainty: A comprehensive review and future research directions. European Journal of Operational Research, 263(1), 108-141.

Jacobs, B. W., & Singhal, V. R. (2020). Shareholder value effects of the Volkswagen emissions scandal on the automotive ecosystem. Production and Operations Management, 29(10), 2230-2251.

Jacobs, D., Choo, K. K. R., Kechadi, M. T., & Le-Khac, N. A. (2017, August). Volkswagen car entertainment system forensics. In 2017 IEEE Trustcom/BigDataSE/ICESS (pp. 699-705). IEEE.

Jung, J. C., & Sharon, E. (2019). The Volkswagen emissions scandal and its aftermath. Global Business and Organizational Excellence, 38(4), 6-15.

Jung, K., Chilton, K., & Valero, J. N. (2017). Uncovering stakeholders in public–private relations on social media: a case study of the 2015 Volkswagen scandal. Quality & Quantity, 51(3), 1113-1131.

Koval, V., Duginets, G., Plekhanova, O., Antonov, A., & Petrova, M. (2019). On the supranational and national level of global value chain management. Entrepreneurship and Sustainability Issues, 6(4), 1922-1937.

Li, L., McMurray, A., Xue, J., Liu, Z., & Sy, M. (2018). Industry-wide corporate fraud: The truth behind the Volkswagen scandal. Journal of Cleaner Production, 172, 3167-3175.

Mačaitytė, I., & Virbašiūtė, G. (2018). Volkswagen emission scandal and corporate social responsibility–a case study.

Painter, C., & Martins, J. T. (2017). Organisational communication management during the Volkswagen diesel emissions scandal: A hermeneutic study in attribution, crisis management, and information orientation. Knowledge and Process Management, 24(3), 204-218.

Payne, A., Frow, P., & Eggert, A. (2017). The customer value proposition: evolution, development, and application in marketing. Journal of the Academy of Marketing Science, 45(4), 467-489.

Russo, M., & Cesarani, M. (2017). Strategic alliance success factors: A literature review on alliance lifecycle.

Siano, A., Vollero, A., Conte, F., & Amabile, S. (2017). “More than words”: Expanding the taxonomy of greenwashing after the Volkswagen scandal. Journal of Business Research, 71, 27-37.

Sodhi, M. S., & Tang, C. S. (2020). Supply Chain Management for Extreme Conditions: Research Opportunities. Journal of Supply Chain Management.

Tanaka, K., Lund, M. T., Aamaas, B., & Berntsen, T. (2018). Climate effects of non-compliant Volkswagen diesel cars. Environmental Research Letters, 13(4), 044020.

To, C. K., Chau, K. P., & Kan, C. W. (2020). The logic of innovative value proposition: A schema for characterizing and predicting business model evolution. Journal of Business Research, 112, 502-520.

Túry, G. (2017). Global or more regional? Analysis of global Embeddedness of the central European's automotive industry via Volkswagen group's intra-firm linkages. Unia Europejska. pl, 4(245), 3-37.

Welch, J. (2019). The Volkswagen recovery: leaving scandal in the dust. Journal of Business Strategy.

Welch, J. (2019). The Volkswagen recovery: leaving scandal in the dust. Journal of Business Strategy.

Whittall, M., Lucio, M. M., Mustchin, S., Telljohann, V., & Sánchez, F. R. (2017). Workplace trade union engagement with European Works Councils and transnational agreements: The case of Volkswagen Europe. European Journal of Industrial Relations, 23(4), 397-414.

Yu, M., & Cruz, J. M. (2019). The sustainable supply chain network competition with environmental tax policies. International Journal of Production Economics, 217, 218-231.

Continue your journey with our comprehensive guide to Volkswagen Case Defeat Devices.

What Makes Us Unique

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts