Energy Harvesting in Public Transport

Chapter One – Project Background and Significance

Introduction

Chapter 1 will present an introduction to this thesis’ topic, providing the background, purpose, and significance of the thesis topic. This chapter will also provide a context into the authors working profession, the company the author works for and how the thesis topic fits and aligns with the company’s business and direction.

Company Background

I am a Civil Engineer working for the Department of Transport and Main Roads (TMR) in Queensland. TMR is a Queensland Government Department responsible for safe, efficient and effective movement and connection of people, places, goods and services (TMR, 2018). This includes pedestrians, cyclists, light vehicles, freight, public transport, and marine (coastal). TMRs role is for the implementation and execution of works in alignment with the policies of the Queensland Government. My role in TMR is Engineer who manage Motorways. I provide engineering technical advice, guidance and direction to the planning, design, and implementation of the Motorways in Queensland, including all associated and effected Intelligent Transport System (ITS) infrastructure. My role is to look at effective and efficient design and management of Queensland’s motorways. At TMR there is now an increasing and greater focus on preparation of the network in the roll-out of autonomous vehicles all across Queensland. Every day there is growing research into new systems, technologies, and developments in the field of cooperative intelligent transport systems globally. This is the background to how and where my proposed thesis topic started. My experience has allowed me to witness the connections and alignments between the emergence of smart, cooperative and intelligent technologies in the transport sector and those aiming for more energy efficient and ‘greener’ technologies. Many projects and initiatives are currently getting invested in the field of renewable energy, greener energy, and smarter energy. This includes electric vehicles, hybrid vehicles, the Tesla’s, energy efficient and smarter vehicles. However, there is currently a gap in the understanding and appreciation of energy harvesting technologies in Australia. Recent policies released by the Queensland Government have fortified the Government’s objectives of climate change and sustainable development, in particular, the Zero Emissions Transport Roadmap (Queensland Government, 2017). There are three critical commitments in the climate strategy in the country including powering Queensland with 50% renewable energy by 2030, achieving zero net emissions by 2050 and reduction of carbon pollution by at least 30% lower than the 2005 levels by 2030 (Queensland Government, 2017). The technologies and benefits of energy harvesting would be very beneficial to Australia’s energy and transport sectors. As such, my thesis will aim to carry out a feasibility study in the field of large-scale energy harvesting technologies through Queensland’s public transportation systems. However, is important to note that acquiring required and enough data about energy harvesting in Australia from various relevant authorities for a comprehensive assessment of comparisons and costs of energy harvesting technologies in this thesis has been a continuing challenge. Therefore, this thesis has only focused in the sector of public transport particularly trains and buses. As I am currently working and residing in the state of Queensland, I would like the focus of my thesis research to be bound to this region. My aim for the future will be to make recommendations for furthering my research to broader areas of Australia.

Project Background

Our understanding and appreciation of energy production and utilization are developing every day. We are increasingly becoming more aware of the negative impacts, particularly the emancipation of greenhouse gases and its contribution towards global warming. Much emphasis is now on the utilization of environmentally friendly products and services, the practice of ‘greener’ lifestyles and the consumption of renewable energy (Smith, 2015). There are many research and development projects in the field of renewable energy that is currently happening and being worked on around the world. Australia is one of the states with its geographical location making it ideal for establishment, testing and implementation of such technologies. According to Smith (2015), Australia’s wind resource is among the best in the world. Its solar energy has the potential to power the country for 10,000 years, its wave energy from the oceans is enough to supply five times of its electricity needs. Additionally, hydrogen gas is plenty (generated by splitting water into hydrogen and oxygen). Approximately a third of the world's uranium (nuclear energy) is in Australia in addition to its sufficiently available geothermal and bioenergy. The Department of Environment and Energy stated that their transport sector is the largest consumer of energy in Australia (Energy.gov, 2018). On the other hand, the Australian transport sector is now becoming more energy efficient, and although emitting fewer greenhouse gases per kilometer, transport demand is increasing at a higher rate and hence resulting in increased greenhouse emissions to approximately one percent per year (Smith, 2015). For gasoline vehicles, CEC (2006) states that only 15 percent of fuel energy gets utilized in cars (Energy.ca.gov, 2018). The U.S. Department of Energy says that approximately 21 to 40 percent of fuel energy from hybrid vehicles is used to drive vehicles while about 72 to 94 percent of the energy is used to power electric vehicles (Energy.gov, 2018). Further, in the report, it is stated that the energy losses for gasoline and hybrid cars are due to their engines (engine friction, pumping of air and wasted heat) and driveline inefficiencies (Energy.gov, 2018). Although electric vehicles are more energy efficient, there are still losses due to charging of battery, braking and powering of accessories (Energy.gov, 2018). Melcher (2016) provides a solution to such losses and inefficiencies by implementation and utilization of energy harvesting technologies within vehicles’ mechanisms and instruments. Melcher (2016) states that energy harvesting has the potential for cleaner and more efficient operating vehicles, hence reducing greenhouse gas emissions and fuel consumption. Energy harvesting is the process of capturing and accumulation of by-product energy as it becomes available. This energy is stored and later used for a variety of applications. This idea and technology, the harvesting of freely available energy are not new with applications such as windmills and watermills from the ancient times (Mide Technology, 2018).

Today’s world has become more complex technologically. The examples of available energy harvesting tech include mechanical energy from vibration, stress and strains, thermal energy from heat of combustion engines, friction and furnaces, electromagnetic energy from inductors, coils, and transformers (S3.amazonaws.com, 2018). In the transport sector, there is currently many research and works occurring in the field of energy harvesting. For instance, CSIRO’s tasks on motion energy harvesting, including capturing of vibration energy from large civil structures such as bridges (S3.amazonaws.com, 2018). It is estimated that the Sydney Harbour Bridge could generate enough power for approximately 200 homes. Thermoelectric generators are another example of recent energy harvesting technology whereby waste heat from car exhaust is captured and transformed into electricity. This energy is then utilized for vehicles’ electrical system, resulting in reductions in engine-load, fuel consumptions and greenhouse gas emissions (Melcher, 2016).

Project Aim

The aim of this thesis is to investigate alternative energy harvesting methods and implement a feasible solution for large-scale energy harvesting through public transport in Queensland.

Project Scope

The scope of this thesis is finding a workable solution for energy harvesting through public transportation which passes by on-road.

Expected Outcomes

The expected outcomes of my thesis will be a better understanding and appreciation of energy harvesting technology in Queensland through its public transport systems. It will be an assessment of energy harvesting systems practicality in operation and implementation. Although this is not and will not be a new system, the outcomes of my thesis will aim at providing an understanding of the current works and researches in the field of energy harvesting and how it can or possibly can benefit the state of Queensland. My ultimate aim will be to suggest the implementation and utilization of this technology for the betterment of Australia. My thesis is a feasibility study and as such my solutions and outcomes will be providing justifications, reasoning and supporting evidence for the effectiveness and practicality of large-scale energy harvesting through public transportation systems in Queensland. I will be offering a detailed assessment of the technology requirements in both Australia and Queensland.

Thesis Structure

This thesis contains six chapters. The first chapter is about introduction of the thesis. The second chapter includes a literature review of the thesis topic which investigates existing technologies used in the world for energy harvesting. The third chapter includes a deep study on existing public transport systems in Queensland. The fourth chapter is about my proposed solution to utilize energy from public transportation in Queensland. The fifth chapter is about solution development and its implementation. The sixth chapter contains cost-benefit analysis and a conclusion of the thesis.

Concluding Remarks

This chapter presented an introduction into the thesis topic, providing the background, purpose, background of the writer and the significance of this thesis’ topic. The aim of this thesis is to investigate alternative energy harvesting methods and implement a feasible solution for generation of large-scale energy harvesting through public transport in Queensland. The expected outcomes of my thesis will be a better understanding and appreciation of energy harvesting technology in Queensland through its public transport systems. It will be an assessment of the energy harvesting systems practicality in operation and their implementation.

Chapter Two – Literature Review

Introduction

This chapter presents a brief review of existing knowledge and information on public transport and energy, alternative energy sources and energy harvesting. Past works and research carried out on energy harvesting and public transport is also examined. A vast study is carried out on the public transport system of Queensland. The economic benefits, environmental benefits and the fields of application of energy harvesting are also reviewed.

Source of Literature

Today, energy harvesting is one of the debated topics for renewable energy. I have looked into the usage of modern technologies for energy harvesting and read different methodologies that are being used locally and internationally. In this regards, research material has been studied which includes research papers, research journals, and articles. These research materials have been analysed and accomplished. The detail of each topic is discussed in this chapter

Review of Literature

Overview

In this chapter, a literature review has been done. The energy harvesting solutions around the world have been explored particularly in Australia. In this regards, different research papers and articles have been read. The research includes traditional methods for energy production, alternative energy solution for electricity production like solar energy, wind energy, and harvesting energy. The advantage and disadvantage of existing electricity production sources have also been discussed. An analysis has been done on energy losses in transportation. Transportation energy can be utilised for production of electricity. A deep study has been done on new renewable energy resources and feasibility to implement harvesting systems locally in Australia especially in Queensland.

Energy

The Oxford dictionary (2018) defines energy as ‘the property of matter and radiation which is manifested as a capacity to perform work such as causing motion or the interaction of molecules. From simple walking to the switching on of lights, the generation of electricity, the use of computers, air conditioners and running of cars, planes, trains, and buses, all require energy to operate and function (Gallagher et al., 2018)

Energy usage

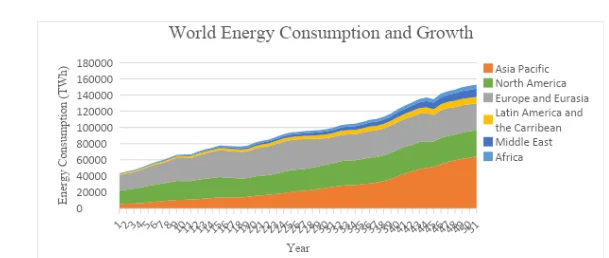

As stated by Ritchie and Roser (2018) a key pillar to the wellbeing, poverty alleviation and economic development is our access to energy. The source, type, and application of energy have developed, evolved and advanced over time (Pant et al., 2010). Figure 2.2 and 2.3 (below) from Ritchie and Roser (2018) illustrates energy consumption by continental regions of the world between 1965 and 2015. It is exemplified in the figure that during this period global energy consumption skyrocketed by more than 350 percent, with Asia Pacific, North America, and Europe contributing the greatest. Figure 2.1 depicts about the world energy consumption and its growth with the passage of time. This figure provides information about energy consumption and its growth in different regions from Asia to Africa. It is apparent from then figures that the consumption is growing continuously.

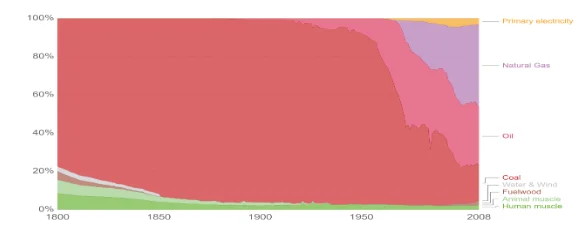

The era of energy consumption started with the use of coal (Ritchie and Roser, 2018). The modern fuels of today have replaced the human energy systems of the past like muscle, food for labor and animal feed. This understanding is critical in highlighting the importance of our reliance and understanding of the transition of energy consumption exemplified in Figures 2.1 to 2.11 below (Ritchie and Roser, 2018). These figures exemplify reliance on energy and their existence. During the 1800’s it is interesting to note the portion of energy exerted and generated from human muscle, animal muscle and fuel from wood. This was particularly true for Italy with approximately 91.5 percent energy exerted (Ritchie and Roser, 2018).

The above figures provide information about consumption of energy in Italy and Canada. This figure depicts consumption of energy in the 18th century. During this period energy was taken from human muscle and animal muscle. With the passage of time, consumption of energy shifted towards fuel-wood in the 19th century (Ritchie and Roser, 2018). In the middle of the 19th century, energy consumption shifted towards water and wind. At the end of this century it shifted towards coal and oil (Ritchie and Roser, 2018). The traditional methods for electricity production depend upon natural resources (Santos et al., 2014). However, natural resources decay continuously making them unreliable (Santos et al., 2014). Nowadays the consumption is shifted towards renewable energies like solar energy, wind energy, and the harvesting of energy (Destek and Aslan, 2017).

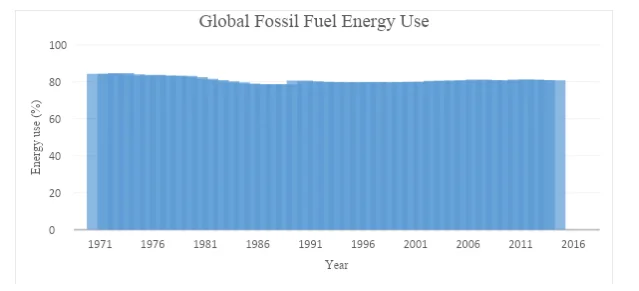

The above figure 2.15 depicts global fossil fuel energy use. Fossil fuel is the main energy source around the world (Wang et al., 2017). Every country depends upon fossil fuel. This figure tells us that about 80% of energy was acquired from fossil fuel between 1971 and 2013. The fossil fuels is a natural source. It is decreasing with the passage of time at a very low percentage. This data depicts that long-term reliability on fossil fuel is unreliable. It also affects the global environment (Peters et al., 2017).

Traditional Energy Sources

A majority of energy generated in Australia is from traditional energy sources. In fact, this is true for approximately 86 percent of electricity generated, which 73 percent is from coal and 13 percent is from natural gas (Lu, Blakers and Stocks, 2017). The importance of traditional methods for electricity production cannot be ignored but these methods are costly and unreliable. The traditional methods depend on natural resources. These natural resources decay with the passage of time and the demand for electricity is becoming high every day. So there will be a gap between demand and supply (Peters et al., 2017). The detail of resources for the production of electricity from traditional resources (including their advantages and disadvantages) are discussed in these next sections.

Petrol (Leaded/Unleaded)

Petrol is the biggest source of energy which is used for the production of electricity. Like other non-renewable energy sources, this fluid is the finished result of long periods of decay of natural materials (Wang et al., 2017). There are three technologies used to convert oil into electricity: The first one is Conventional steam where Petrol is burned to heat water to create steam to generate electricity (Jamal et al., 2017). The second technique is the use of Combustion turbines where Petrol is burned under pressure to produce hot exhaust gases which spin a turbine to generate electricity (Jamal et al., 2017). Additionally, there is Combined-cycle technology where Petrol is first combusted in a combustion turbine, using heated exhaust gases to generate electricity. After these exhaust gases are recovered, they heat water in a boiler, creating steam to drive a second turbine (Jamal et al., 2017). One of the main challenges for using petrol is that despite of it being a natural source, it is decaying from the soil (Gray and Taylor, 2018). Furthermore, the demand for energy is getting high with the passage of time. Hence the cost of petrol is increasing due to a shortage of petrol worldwide. Therefore, it is not a permanent sustainable solution for energy production (Gray and Taylor, 2018).

Diesel

Diesel generators are very useful machines that produce electricity by burning diesel fuel (Choichan et al., 2018). These machines use a combination of an electric generator and a diesel engine to generate electricity (Choichan et al., 2018). Diesel generators convert some of the chemical energy, contained by the diesel fuel, to mechanical energy through combustion. This mechanical energy then rotates a crank to produce electricity. Electric charges are induced in the wire by moving it through a magnetic field (Choichan et al., 2018). In an electric generator application, two polarised magnets usually produce the magnetic field. A wire is then wound around the crankshaft of the diesel generator many times, which is placed between the magnets and the magnetic field (Choichan et al., 2018). Diesel is a bi-product of crude oil. This method of producing electricity is very expensive and natural energy resources are decaying by the time. So it is not a reliable and permanent solution (EnergyInst.org, 2018). The challenge of using diesel is that torque is less in diesel, consequently the pulling force is less. The idling performance of diesel is weak. It expends a high amount of fuel while running on low rpms (revolutions per minute). Besides, the overall fuel efficiency is less so the amount of consumption is high and hence fuel cost of the vehicle becomes high. The diesel source is natural and natural resources are decaying with the passage of time, hence it is not a long-term reliable solution (EnergyInst.org, 2018).

Gas (LPG)

Liquefied petroleum gas (LPG) is an excellent choice of fuel for power plants where natural gas for various reasons is not available. There are a number of reasons for the increasing popularity of LPG for power generation. LPG is a cleaner fuel than heavy fuel oil as well as LPG is traded as a commodity worldwide making it readily available. Its transportation is easy by sea, rail or truck, regardless of batch size. Its storage of LPG is relatively simple and does not require cryogenic storage tanks. Lastly, the distribution infrastructure for LPG is readily available in many countries as it is used for transportation, industry and also small-scale heating and cooking (Gastgivers, 2017). This gas is also a less expensive method for electricity production as well as it is the most popular method to produce electricity. But it is a natural resource that decays with time. So it is not a long-term solution for energy production (Gastgivers, 2017). The main challenge of using LPG is that to liquefy Methane, the main component of Natural Gas, it needs to be chilled down below -164 Celsius which consumes a lot of energy (Gastgivers, 2017). Keeping it below that temperature constantly performs active cooling of the tanks. For a ship loading LPG from a port and taking it to the destination, the quantity of energy needed to first liquefy and then maintain LPG in a liquid state amounts to 10–25% of the energy generated when the LPG is liquefied. Due to the wastage of energy in compression, the cost of using LPG gas becomes high (Gastgivers, 2017). The production of electricity through mechanical technology is environmentally unfriendly. It is also protected and reliable. Energy output is also predictable and high (Behnam, Arefi, Shafii, 2018). However, wear on the parts may limit lifespan and piezoelectric materials used in some devices may become faulty over time. The machine size is another issue with electromagnetic devices. There is also limited practical operational duration with this technique (Behnam, Arefi, Shafii, 2018). Another technique is thermal or pyro-electric Energy which has a long lifespan and the potential for human body-worn applications. But it produces low energy. That is why it has higher cost, low power output (about 40µW/cm3); limited usage due to higher temperature gradient requirements and the power output depends on thermal gradient conversion efficiency (Namdeo and Pawar, 2017). Biochemical Energy production on the other hand provides availability of constant fuel source and implantable applications for human beings. But this technology is sensitive to the external environment and is not available commercially. There are also limitations on the lifetime and reliability of biological components (Ladd et al., 2018).

Alternative Energy Sources

Alternative energy sources are not acquired from fossils (Prodan, 2017). The traditional methods for electricity production are not cost effective. Its resources are decaying with the passage of time. If countries depend only traditional methods then it will create a problem in the production of electricity, demand will be high. Ultimately it affects the economy of countries unable to fill the gap between energy demands and supply (Santos et al., 2014). Alternative energy sources are used to address the issues of fossil fuel like emission of carbon dioxide and global warming (Prodan, 2017). Alternative Energy sources are cost effective and provide a long-term solution. Most countries are investing in an alternative source like solar energy, wind energy and harvesting energy (Prodan, 2017). The detail of the alternative source is discussed in the next section.

Solar:

Solar energy is radiant light and heat from the sun that is harnessed using a range of ever-evolving technologies such as solar heating, photovoltaics, solar thermal energy, solar architecture, molten salt power plants, and artificial photosynthesis (Green et al., 2017). It is an important source of renewable energy and its technologies are broadly characterised as either passive solar or active solar depending on how they capture and distribute solar energy or convert it into solar power (Green et al., 2017). Active solar techniques include the use of photovoltaic systems, concentrated solar power, and solar water heating to harness the energy. Passive solar techniques include orienting a building to the Sun, selecting materials with favorable thermal mass or light dispersing properties, and designing spaces that naturally circulate air (Green et al., 2017). The main challenges of using solar energy are that the solar energy is stored in battery that has a very limited lifetime. Hence the operation cost becomes high (Green et al., 2017). The power output of solar panels is expressed as watts, which is a measure of the amount of electricity that can be generated by the solar panel. Solar panels for domestic purposes typically produce between 225 to 360 Watts of electric output (Theecoexperts.co.uk, 2018). Sometimes, solar panels are not able to fully maximize electricity production as this depends on the outside temperature and number of hours it is exposed to sunlight (Theecoexperts.co.uk, 2018). Solar energy is also used in transportation. The first bus to use solar energy was introduced in 2013 in Australia, Adelaide by the Adelaide city council (Greenmatch.co.uk, 2018). This was with the intention to reduce carbon emission by the city. This buses totally rely on electricity to operate. The bus has a battery that is charged back in the city. The battery can last for over 200km then it is drained and requires a recharge. The battery life of these buses is also extended slightly by their regenerative brakes (Greenmatch.co.uk, 2018).

Wind

Wind power is the use of air flow through wind turbines to provide mechanical power to turn electric generators (Gebraad et al., 2017). Wind power, as an alternative to burning fossil fuels, is plentiful, renewable, widely distributed, clean, produces no greenhouse gas emissions during operation, consumes no water, and occupies small space on land. The net effects on the environment are far less problematic than those of non-renewable power sources (Gebraad et al., 2017). Wind farms consist of many individual wind turbines, which are connected to the electric power transmission network. Onshore wind is an inexpensive source of electric power, competitive with or in many places cheaper than coal or gas plants (Gebraad et al., 2017). Offshore wind is steadier and stronger than on-land and offshore farms have a less visual impact, but construction and maintenance costs are considerably higher (Gebraad et al., 2017). Small onshore wind farms can feed some energy into the grid or provide electric power to isolated off-grid location. The main challenge of using wind energy is that wind energy depends on the wind which is a natural source. The wind plant is implemented in those areas which have a high wind speed. But sometimes the wind does not blow to generate energy. Therefore it increases the operation cost of the plant. Hence the cost of generating energy becomes high (Gebraad et al., 2017).

According to Sciencing (2018), the latest wind turbines have unique designs that aid in capturing wind efficiently. In an ideal environment, a wind turbine can convert 100% of passing wind into power. However, due to factors like friction, wind turbines have efficiency of 30% to 50% in terms of electricity output. The power output of wind turbines is calculated as follows:

Electric power= [(Air density)*(Swept area of blades)*(Wind speed)]/2

Area is in M2

Air density is in Kg/M3

Wind speed is in M/Sec

According to Sciencing (2018), just because a turbine has a certain megawatts rating does not mean it will generate the exact amount of power practically. They often generate considerably less power than their rated capacity. Nonetheless, Sciencing (2018) claim that industrial scale wind turbines have the potential ratings of two to three megawatts. This amount of power is however often reduced by wind availability and efficiency (Sciencing, 2018). There are evidences that trains can be powered by wind energy. According to the Phys.org (2018), all Dutch trains are being powered using wind energy. A single windmill running for one hour is able to power a train across approximately 200kilometres (Phys.org, 2018). Additionally, there are evidences that buses and trucks can be powered by wind energy. According to Tony (2018), wind turbines are driving the bus and truck fuel economy. Tony (2018) point out that wind turbines operate by disturbing air as they move through it. He further says that buses and truck also cut through air. Therefore, the scientific principle of wind turbines and buses or trucks of cutting through air are similar. Buses and trucks are fitted with wind turbines attached with EcoFin Vortex Generators to enhance aerodynamics around them and increase energy production (Tony, 2018).

Transport and Energy

Activities of transportation are responsible for huge energy consumptions when they offer mobility to freight and passengers. Transportation accounts for at least 25% of the total energy consumption worldwide (Wu, Yuan and Xin, 2017). Transport and energy sources can be used to boost the development of sustainable transportation systems because these sources are renewable and have a lower environmental impact than diesel and gasoline. The transport energy can be utilised to produce electricity and this electricity can be sent to the grid station (Wu, Yuan and Xin, 2017). The market of transportation gets affected by three factors, volatility and price levels of energy, energy performance levels through technical and technological changes, and environmental externalities. Research shows that transportation accounts for about 61.5% of the total oil consumed every year (Wu, Yuan and Xin, 2017). Its detail is discussed in the next section.

Transport in Australia

There are many forms of transport in Australia, including road, rail, sea and air. Australia is highly dependent on road transport. There are more than 300 airports with paved runways. Passenger rail transport includes widespread commuter networks in the major capital cities with more limited intercity and interstate networks (Black, 2018). The Australian mining sector is reliant upon rail to transport its product to Australia's ports for export (Black, 2018). There are 3 different categories of Australian roads. They are federal highways, state highways, and local roads. The road network Intra-city public transport comprises a total of 913,000 km broken down into Commuter rail, Trams, and light rail Rapid transit (Williams, 2017). Investment in Australia’s total road network has been relatively constant at around one percent of GDP since at least the late 1980s, with a significant increase from the early 2000s (Figure 3). This reflection both increased Commonwealth and private sector (PPP) funding. PPP stands for purchasing power parity and is a theory, an economic concept which elaborates how the exchange rate of currencies is in equilibrium with each other especially when the currencies’ purchasing power is equal or the same in every one of the two states (Williams, 2017). The National Highway system link connects all the state and territory capitals and terminates at the edge of each capital city. It was established under the act ‘to encourage and contribute, to a major extent, to trade and commerce, overseas and among States (Williams, 2017). Road transport is an essential element of the Australian transport network and an enabler of the Australian economy. There is a heavy reliance on road transport due to Australia's large area and low population density in considerable parts of the country (Black, 2018). Another reason for the reliance on roads is that the Australian rail network has not been sufficiently developed for a lot of freight and passenger requirements in most areas of Australia (Lennox and Dixon, 2018). This has meant that goods that would otherwise be transported by rail are moved across Australia via road trains. Almost every household owns at least one car and uses it most days (Black, 2018). Australia has the second highest level of car ownership in the world. It has three to four times more roads per capita than Europe and seven to nine times more than Asia (Black, 2018). Australia also has the third highest per capita rate of fuel consumption in the world (Parker et al., 2018). Melbourne is the most car-dependent city in Australia, according to a data survey in 2010 (Rissel et al., 2018). Melbourne has 110,000 more cars driven to and from the city each day than Sydney. Perth, Adelaide, and Brisbane are rated as being close behind. All these capital cities are rated among the highest in this category in the world (car dependency) (Rissel et al., 2018). The distance traveled by car (or similar vehicles) in Australia is among the highest in the world, exceeded by USA and Canada (Rissel et al., 2018).

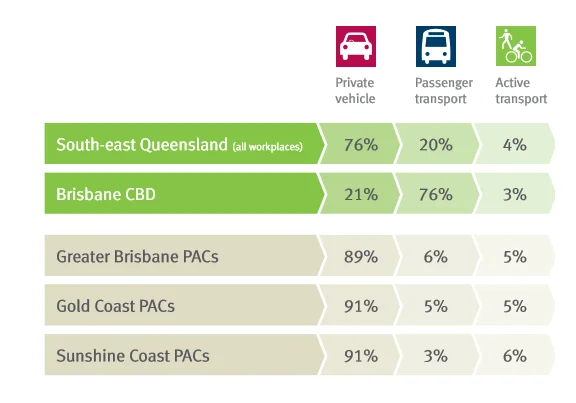

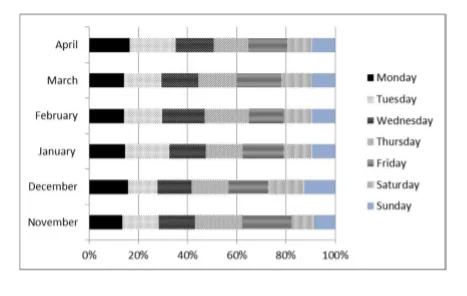

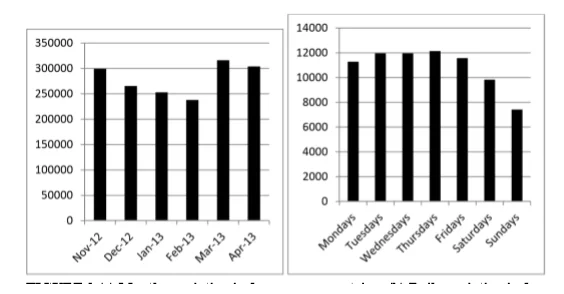

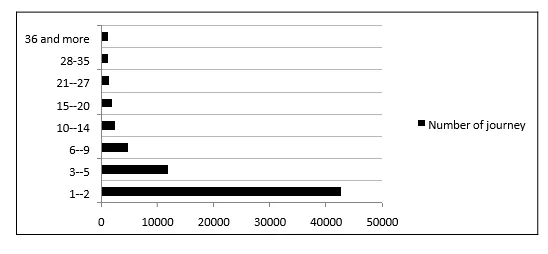

Public Transport in Queensland

In Queensland public bus services are coordinated by the Queensland Government's Department of Transport and Main Roads (TMR) and provided by over 1000 operators (Yen et al., 2017). The coordination of public bus transport generally falls under three schemes: TransLink services, QConnect services and the remaining rural/regional school services. There are also private bus services in Queensland offered by some operators (Yen et al., 2017). The public trains in Queensland are managed by the Queensland rail. Queensland rail not only is a monopoly rail system but also has the obligations and responsibilities under law to offer transparent and open access to its systems for all operators under the Queensland Competition Authority (Queenslandrail.com.au, 2018). Brisbane is Queensland’s third most populated city as well as its capital. In Brisbane alone, people spend 68 minutes commuting through public transport on weekdays (Moovitapp.com, 2018).

Besides, 23% of Brisbane’s population use public transport every day for two hours including Ferry, Bus, Train and Light rail. These 23% of the population cover an average of 9.0 km (single journey e.g. from work) (Moovitapp.com, 2018).

Energy usage/losses in cars

No less than one-third of a car’s fuel consumption is spent in overcoming friction, and this friction loss has a direct impact on both fuel consumption and emissions (Liu et al., 2018). There are 612 million cars in the world today. The average car clocks up about 13,000 km per year, and consumes 340 liters of fuel just to overcome friction, costing the driver EUR 510 or 818.1 Australian Dollars per year (Liu et al., 2018). Of the energy output of fuel in a car engine, 33% is spent in the exhaust, 29% in cooling and 38% in mechanical energy, of which friction losses account for 33% and air resistance for 5%. By comparison, an electric car has only half the friction loss of that of a car with a conventional internal combustion engine (Liu et al., 2018). Annual friction loss in average car worldwide amounts to 11,860 MJ: of this, 35% is spent in overcoming rolling resistance in the wheels, 35% in the engine itself, 15% in the gearbox and 15% in braking (Mozafar et al., 2018). With current technology, only 21.5% of the energy output of the fuel is used to actually move the car; the rest is wasted (Litman, 2017). Reductions in frictional losses will lead to a threefold improvement in fuel economy as it will reduce both the exhaust and cooling losses also at the same ratio (Litman, 2017).

Energy usage/losses in buses

There is energy losses in buses due to friction. There are 200 million buses in the world today. Friction is an important energy consumer in transportation in buses representing some 15 to 20 % of the total usage of energy. The frictional usage/losses are 21 % of the total fuel energy and of this is 5 % consumed in the tire-road rolling contacts, 3 % in elastohydrodynamic contacts, 3 % in hydrodynamic contacts, 2 % in mixed and 2 % in boundary lubricated contacts. Viscous losses are 2 % and braking takes 4% (Masanes and Oppenheim, 2017).

Energy usage/losses in trains

The first law of thermodynamics says that energy cannot be created or destroyed; it can only change form (Masanes and Oppenheim, 2017). The South-eastern Pennsylvania Transportation Authority (SEPTA) are launching a project to build a battery storage network for its railway network that will capture and reuse energy released by the braking of its subway cars. SEPTA subway cars use a lot of energy, but then cast it off each time one of them stops at a station. When complete, the network will be one of the largest customer sited battery storage systems (the first commercially deployed for a transit operation) and serve as a model for using stored energy to supply power in congested parts of the grid (Warner et al., 2017).

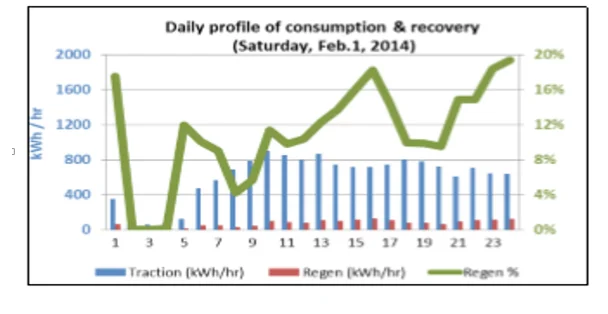

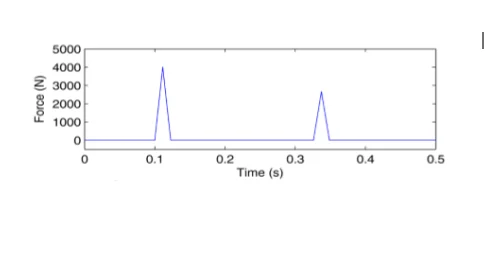

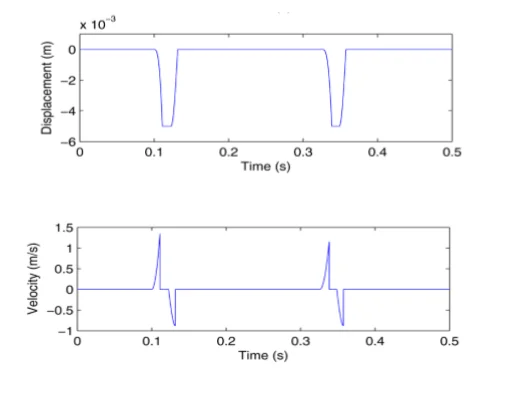

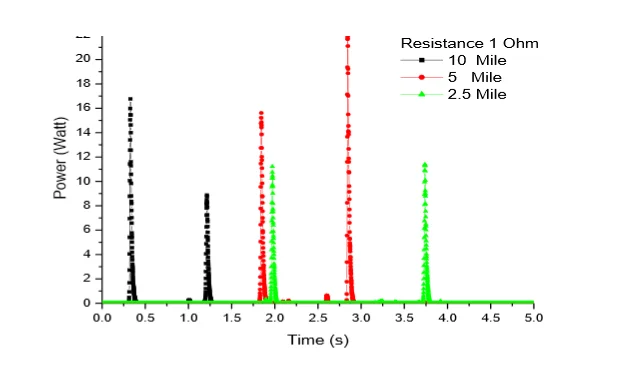

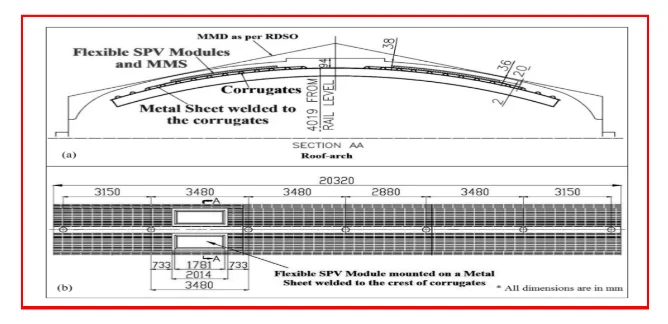

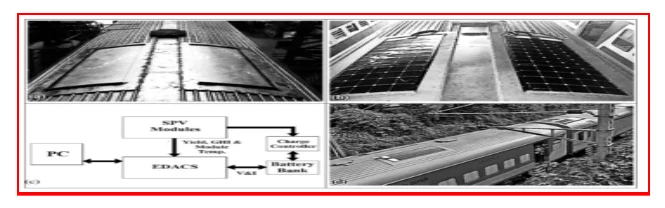

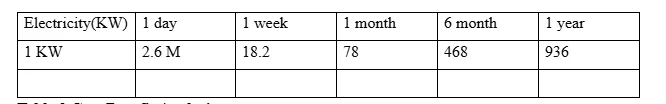

This diagram above shows energy recovery by event count and size. The profile shown for energy recovery is a function of the rate of stopping of the train. The table presents a profile as a fraction of the entire energy traction. The frequency of recovery decreases below 5% of the total traction energy at peak hours and above 20% at off-peak hours. The energy produced by these trains can be harvested to generate electricity (Septa.org, 2018). The possibility of scavenging electricity from railcar traffic was investigated by Nelson and colleagues (2008) by using piezoelectric devices and a technique of inductive voice-coil. Passing railcars over the piezoelectric devices (placed below the rails) caused a significant longitudinal strain. The longitudinal strain was then converted to electricity. An alternative method also investigated by these researchers was the use of an inductive voice-coil which was attached to a railroad. This device was driven by the rail’s vertical displacement. The average electricity harvested was about 1 mW for both the inductive voice-coil and the piezoelectric devices (Nelson et al., 2008). These techniques show great potential for the generation of electric energy and can also be used in Queensland rail network to produce energy.

Ferries:

A ferry is a merchant vessel used to convey travelers, and sometimes vehicles and freight operating on water. A public ship has numerous stops within the sea and many stations like public buses. Ferries are cost-effective public transport in numerous countries which has waterside urban areas and islands, permitting to travel to different coastal stations. The ferry travel needs very low capital route because if public buses get used in these routes, then the government needs to construct bridges over the sea. So the ferry is a very suitable public transport system used in Queensland. The ferry travel is also suitable for t he environment as compared to buses and rail because normal carbon dioxide outflows by ships per traveler kilometer appear to be 0.12 kg which is ideal for the environment and does not have the effects of global warming (Abs.gov.au., 2018).

The usage of public transport (Train, Bus and Ferry)

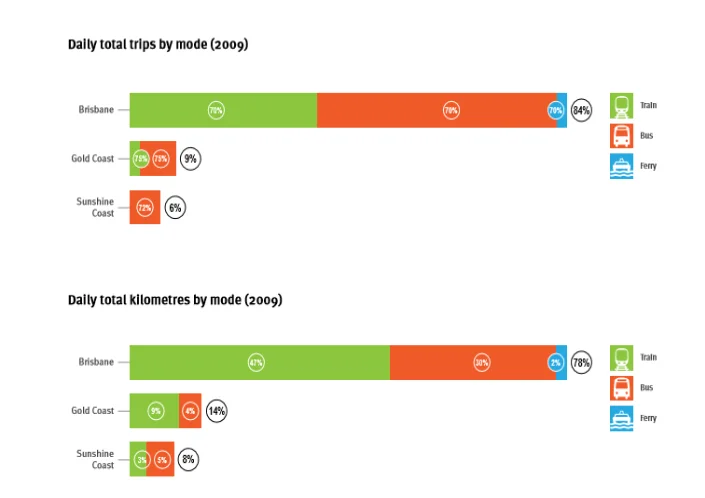

Brisbane residents make the majority of trips in South-East Queensland in regarding public transport. 84% of all trips in the public transport sector in terms of kilometres.

Harvesting

Energy harvesting is a process that takes small amounts of energy that would otherwise be lost such as heat, light, sound, vibration or movement (Xia and Shull, 2018). Energy harvesting also has the potential to replace batteries for small, low power electronic devices. One of the earliest applications of ambient power collected from ambient electromagnetic radiation (EMR) is the radio. This has several benefits such as no costs of maintenance free as there is no need to replace batteries. It is also environmentally friendly as disposal of batteries is tightly regulated because they contain chemicals and metals that are harmful to the environment and hazardous to human health. It also opens up new applications like deploying energy harvesting sensors to monitor remote or underwater locations (Xia and Shull, 2018). The history of energy harvesting dates back to the windmill and the waterwheel. People have searched for ways to store the energy from heat and vibrations for many decades. One driving force behind the search for new energy harvesting devices is the desire to power sensor networks and mobile devices without batteries. Energy harvesting is also motivated by a desire to address the issue of climate change and global warming (Xia and Shull, 2018). Energy harvesters provide a very small amount of power for low-energy electronics. While the input fuel to some large-scale generation costs resources (oil and coal), the energy source for energy harvesters is present as ambient background. For example, temperature gradients exist from the operation of a combustion engine (Xia and Shull, 2018). And in urban areas, there is a large amount of electromagnetic energy in the environment because of radio and television broadcasting (Matteo et al., 2017).

Small Scale Energy Harvesting

The production of nano-scale devices has drastically increased with the rise in technological applications, yet a major drawback to the functionality of nano-sized systems is the need for an equally small energy resource (Hsieh and Tsai, 2018). To address this need, the students of the University of Ahvaz in Iran have been modeling new piezoelectric energy harvester (PEH) technology at the nano-scale level. The team determined how small-scale dimensions impact nonlinear vibrations and PEH voltage harvesting (Zhu et al., 2018). According to Yeatman (2009), there are harvesting devices measuring as low as some cm to mm with energy output of micro-watts to milliwatts. Piezoelectric materials generate electricity from the application of mechanical stress and are utilised in everything from cell phones to ultrasonic transducers (Zhu et al., 2018). This electricity can also be generated by vibration-induced stresses, allowing scientists to create PEHs. These PEHs can be miniaturised down to a micro or nanosize and used in conjunction with nano-scale devices (Zhu et al., 2018). "Nowadays, the need for new miniaturised wireless sensors is growing. These MEMS [Micro-Electro Mechanical Systems] or NEMS [Nano-Electro Mechanical Systems] sensors usually require a power source of their size" (Sciencedaily, 2018). Piezoelectric energy harvesting is a well-known process for converting energy available in an environment into energy that can power small electric devices (Mide Technology, 2018). Traditionally, this has been used for generating a self-sufficient energy supply. Self-sufficiency is highly desirable for nano-scale devices due to the complicated nature of replacing small energy systems (Zhu et al., 2018). PEHs are gaining popularity for nano-scale applications due to their relatively simple structures, higher energy densities and ability to easily be scaled down (Zhu et al., 2018). Macro-scale models have been extensively studied and provided a strong base point to produce nano-scale models. Foruzande, Hajnayeb, and Yaghootian are taking advantage of these adaptable qualities and have generated nano-scale PEH models based on non-local elasticity theory (Zhu et al., 2018). "It's necessary to use this theory for other systems at nano-scale and also the sensors in nano-scale, which use piezoelectric materials (Sciencedaily, 2018)." Research teams have studied nonlinear vibrations and voltage based on nonlocal elasticity theory, which states that a point stress is dependent on the strain in a region around that point (Sciencedaily, 2018). Using this theory, they could derive nonlinear equations of motion with straightforward solutions. Their results showed that adding a nanobeam tip mass and increasing the scale factor would increase the generated voltage and vibration amplitude, hence increasing energy output (Sciencedaily, 2018). Modeling micro- and nano-scaled PEHs was also able to reveal just what impact size effects had on the output they could expect. The researchers found that the error of neglecting size is significant when comparing macro and micro PEHs. Neglecting various size effects resulted in lower estimations of PEH vibrations. Nano-scale sensor technology is becoming a hot commodity in the scientific industry due to its expansive applications. With applications in medicine, engineering, physics and more, nanotechnology has a lot to gain from the use of a stable energy source, such as these newly modeled PEHs (Sciencedaily, 2018).

Large Scale Energy Harvesting

Zuo and Tang (2013) point out that large-scale harvesting machines could produce one watt to 100 Kw or more Nowadays, harvesting energy from vibration is one of the most promising technologies. However, the majority of current researches show 10 µW to 100 mW power, which has limited applications in self-powered wireless sensors and low-power electronics (Musa et al., 2018). In fact, the vibrations in some situations can be very large, for example, the vibrations of tall buildings, long bridges, vehicle systems, railroads, ocean waves, and even human motion. With the global concern on energy and environmental issues, energy harvesting from large-scale vibrations is more attractive (Musa et al., 2018).

Other forms of large scaling

Tidal, Wave and Hydro Power

Energy from natural waves and tides can be harvested and utilized as clean and pollution-free electricity. Waves move along the ocean allowing the time of their arrival at the wave electricity facility more predictable as compared to wind. Tides are caused by the pull of gravity of the Sun or moon and can be predicted before they occur (Ltd, 2018). There are ambitious tidal power projects that are already producing 1.5 Mega-watts using their turbines (Eia, 2018). This has already happened in South Korea and in Scotland (Eia, 2018). In fact Scotland is planning to establish tidal turbines with the potential of producing 400 megawatts (Eia, 2018). Tidal energy, wave energy and hydro-electricity are mainly used for the generation of electricity. For instance, Tidal energy is used to produce 240 Megawatts of electricity at low costs in France. There are also smaller plants that produce sufficient commercial level Tidal electricity that are used in homes (Abhishek, 2011). Tidal energy particularly tidal barrages are used as energy reservoirs and to protect the coast during high storms (Abhishek, 2011). The first tidal lagoon construction began in 2016 along the Swansea’s Welsh city coast. The project is designed to be an enclosing of 11km2 and will generate 320 megawatts of electricity. This amount is sufficient to power over 155,000 homes thereby making it the world\s largest tidal power plant (Andrew Farris and Charlotte Helston, 2017).

Thermoelectric Energy Harvesting

Environments which naturally have heat flow and temperature gradients can produce electricity using a conversion mechanism known as thermal-to-electricity conversion of energy. A difference in temperature provides the ability for energy conversion that is efficient. However, even with sufficient heat flow, the expectable energy or power is usually low because of low material and Carnot efficiencies. Moreover, low heat presence also limits power production. Nonetheless, with exceptionally-low power systems like remote sensors that are wireless, thermoelectric power harvesting is seen as a viable method which is promising to be very prevalent because energy requirements for these devices decline (Ltd, 2018). According to Dahoon and Kyungwho (2018), a thermoelectric energy harvester stores electric power after harvesting generated waste heat by passing railroad vehicles. These individuals studied a thermoelectric module which was applied to change the temperature difference between the axle bearing housing surface and the air outside the housing into electricity. In their study, they conducted a lab-test on the output performance caused by the temperature difference and maximised the process through a computational fluid assessment of the fins that caused cooling. Their optimized thermoelectric power harvesting system was modelled and used on rolling stock. They then analysed electricity generation under operation. After about 57 min of the rolling stock including 300km/h maximum speed interval, 0.4 V, maximum open-circuit energy, was measured. Dahoon and Kyungwho (2018) claim that this energy can be used to self-power monitoring systems which are independent particularly low-power sensor nodes.

Triboelectric energy harvesting

Another technique is triboelectric energy harvesting which uses two principles operating collaboratively or in conjunction. The first principle is the electrostatic induction and triboelectric effect. Triboelectric effect or contact electrification occurs when two surfaces that are charging are brought in contact with each other (Ltd, 2018). This form of energy harvesting may be considered to be a type of electrostatic energy production because of how it works where an electric field is applied to collect produced generated energy. Triboelectric technique is based on the criteria of triboelectric effect. This effect comes due to contact electrification where some materials are electrically charged after they come in contact (also known as static electricity) (Panat, Wang and Parks, 2014). The contact electrification occurs from an electrical output from a polymer electret after the materials are in physical contact with each other. After the materials come together, they pass electrical charges to each other. Triboelectric energy harvesting techniques have improved significantly with time and are becoming applied in many areas. However, many researches on the technique focus on its optimization and development in terms of contact geometry, energy sources and power output (Wang, Chen and Lin, 2015). There has been advancements of smaller tribolectric energy harvesters known as triboelectric nanogenerators in the few past years (Wang, 2013). Triboelectric harvesters have also been used with different methods of harvesting energy to increase their benefits and decrease the weaknesses from each of the techniques. For instance the coupling of triboelectric and piezoelectric vibration harvesting (Han et al., 2015). There is also the coupling of triboelectric and electromagnetic harvesting for sensors that are self-powered (Fan et al., 2014). A group of a Chinese collaborator and a group of engineers from the University of Wisconsin-Madison have built a triboelectric-nanogenerator which is capable of harvesting energy from friction of a rolling car tire (Mao et al., 2015). The generator was able to change mechanical energy into electric energy using the triboelectric principle (the production of electric charge from rubbing together or contact of two different objects). Their nanogenerator relied on the triboelectric ability to produce energy from the electric potential which was changing between the vehicle’s wheels and the pavement (Mao et al., 2015). In this project, the electrons movement was able to produce sufficient electricity to power bulbs. Their results supported the idea that energy which is lost through friction can be harvested and reused (Mao et al., 2015). Such projects show that this technique is very promising in terms of energy harvesting and can be used in Queensland roads to harness energy.

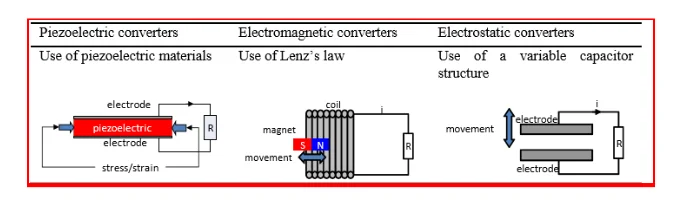

Piezoelectric energy harvesting

Piezoelectric devices are usually appropriate for harvesting small-scale energy (1-10cm3) (Boisseau, Despesse and Seddik, 2012). Piezoelectric energy harvesting is very common in addition to being well researched in the field of mechanical power or energy harvesting. These appliances operate using a property of material called piezoelectricity. This material generates voltage or charges under mechanical stress stimulation. Various materials exhibit piezoelectricity like lead zirconate titanate, quartz, zinc oxide, polyvinylidene fluoride, and aluminum nitride (Hybrid Energy Harvesting Systems Using Electromagnetic and Piezoelectric Materials, 2015). The most commonly used materials in the piezoelectric technology are polymeric PVDF and ceramic PZT (Anton, Farinholt, and Erturk, 2014). The most recent development in this harvesting technology is the use of piezoelectric foam which is most preferred because of its relative strength as compared to the traditional ones (Kar-Gupta and Venkatesh, 2006). Most peizoelectric forms are made from Polythylene Terephthalate and Polypropylene (Anton, Farinholt, and Erturk, 2014). These devices have high voltage output. Piezoelectric devices can be placed in pavements to harvest energy. Research conducted by Xiaochen et al (2017) have shown that these devices can be installed in urban highways and roads. When vehicles run on these roads in high speed, the frequency of vibration in these piezoelectric boxes increases hence increasing the amount of energy generated. Although piezoelectric devices efficiency in energy collection is not sufficient for large-scale energy requirements, it is more appropriate for traffic facilities like traffic indicator brand and reminding on vehicles which are in the wrong or opposite direction (Xiaochen et al., 2017). The advantage of this technique is that it does not need long-distance power thereby allowing the possibility of traffic equipment’s to power themselves (Xiaochen et al., 2017).

Electromagnetic Energy Harvesters

The other form of energy harvesting is using electromagnetic energy harvesters. These harvesters operate on Faraday’s principle of induction. Many transformers, electrical motors, generators, and inductors use this fundamental working principle. The electromotive force or voltage produced in a circuit which is closed is directly proportional to the whole or total flux through this closed circuit (Hybrid Energy Harvesting Systems Using Electromagnetic and Piezoelectric Materials, 2015). The resultant energy of an electromagnetic energy harvester is 0.5 volts to 2.0 volts. Energy harvesting using electromagnetic harvesters can acquire energy from radio waves and vibrations. The coil and magnet can undergo interactive motion due to physical motion or vibrations. These activities can occur in seconds and may produce large amounts of energy (Beeby, Tudor and White, 2006). Currently electromagnetic energy harvesters are being applied in powering portable devices and wireless sensors (Beeby, Tudor and White, 2006).

Electrostatic electricity harvesters

Electrostatic energy harvsters generate 2V to 10V. The last type of energy harvester is using electrostatic electricity harvesters which operate on the variable plate capacitor principle. The mechanical energy which is present in the environment changes the space between two adjacent parallel plates. Together, these plates form a capacitor. The change in this gap results in charge flow exterior of a load linked across two platters. Electrostatic power harvesters which use a physical mechanism is differentiated basing on relative motion between two plates (Li, Misra and Gregori, 2017). Static electric energy can be used to control pollution by applying charge to dust molecules in the air. These dirt particles are then collected on a plate having opposite charge as the dirt (Ron, 2014). Electrostatic energy is also being used to paint cars. Many automobile producers first prepare the car surfaces. They then give the paint to be used an electric charge before spraying it (fine mist) into the painting booth. The paint particles which are charged are attracted to the car’s body. Once it dries, the paint sticks properly giving the car a smoother, finer look as the paint is distributed evenly on the car body (Ron, 2014).

Energy Harvesting in Australia:

The first step has been taken with a Mandatory Renewable Energy Targets, providing a powerful signal that the government is committed to supporting renewable technology (Ma et al., 2017). The challenging 20% renewable by 2020 target provides an opportunity for the supporters of such technology to demonstrate the capability of their industry (Ma et al., 2017). The issues associated with future energy options in a carbon-constrained world have been dominant themes for the Australian Institute of Energy in 2009. The eight branches and members across Australia are providing an informed debate on future energy supply, emission reduction programs, and complementary measures (Ma et al., 2017). Teams from Australia’s own CSIRO are developing technologies in vibration energy harvesting – from clothing to large structures, such as bridges and roads. Dr. Sam Behrens presents the latest from CSIRO’s Division of Energy Technology. One such project that has evolved into a start-up research company is the Windbelt, now under development by Humdinger (ABC NEWS, 2018). Humdinger claims that the Windbelt mechanism of generating energy requires no bearings thus making it efficient as compared to other processes of energy generation like wind turbines that are scaled down but experience tremendous friction. Windbelt energy generation is also preferred mostly for small-scale devices like in LED lights which are powered and used in rural communities (S3.amazonaws.com, 2018). Additionally, because of its aeroelastic flutter nature, Windbelt is adjustable or tuned to maximize or optimize its output at varying wind speeds (S3.amazonaws.com, 2018). The Humdinger firm also claim that Windbelt is quite cheap to manufacture or produce notably the smaller versions. They also have a longer lifespan of at least 20 years. Humdinger firm say that these devices can be readily built in countries which are still developing. The current application of Windbelt technology faces one challenge which is technology relativeness. Different Windbelt sizes are not yet becoming widely produced. Hence each Windeblt must become designed and developed individually (S3.amazonaws.com, 2018). Windbelt is less complicated as compared to the construction of conventional turbines. Additionally, developing wind turbines requires other mechanical units and gears to aid in rotating this turbine so that electricity gets generated. Very light winds to cause vibrations on its membrane and generate electricity. In fact, there is a prototype of Wind belt about ten to thirty times effective as than to micro turbines. Also, since the building of Wind belt is not expensive, it becomes a better alternative particularly in places where kerosene is applied for smaller power amounts. Humdinger says that while kerosene produces unhealthy smoke which is a health risk to humans causing health problems, Wind belts can be used to alleviate such challenges (S3.amazonaws.com, 2018).

Energy Harvesting around the World:

Energy harvesting is a process that takes small amounts of energy that would otherwise be lost such as heat, light, sound, vibration or movement (Du et al., 2017). Energy harvesting also has the potential to replace batteries for small, low power electronic devices. Now it is the era of renewable energy and it provides the best solution to produce electricity. Countries are shifting its energy sources towards harvesting energy. Traditional methods for energy generation are not reliable for the long term because fossil fuel is decreasing with the passage of time. If countries depend on fossil fuel then the gap between demand and supply of energy cannot be filled (Peters et al., 2017). Fossil Fuels are also affecting the global environment (Peters et al., 2017). The followings are researches which have been implemented in different countries.

Israel Model to generate electricity Using Piezo-electronics Devices

Israeli engineers have tested a 100 meter stretch of roadway installed with a system of Piezo Electric Generators (Schwartz, 2018). The piezoelectric effect converts mechanical strain into electrical current or voltage and the system is required to scale up to 400 kilowatts from a 1-kilometer stretch of double carriageway. The spearheading creation in the field of Parasitic is on the basis of energy collection which produces energy from weight, movement, vibrations and temperature changes and has other parasitic energy gathering applications in numerous fields (Schwartz, 2018). At first, however, the system can be arranged to produce and store energy from road, airplane terminal runways and rail system. The harvested energy from different resources can be exchanged back to the grid, or utilised for particular infrastructure purposes, such as lighting. The use of the system would enable greater scrutiny and thus comprehension of the conduct of road vehicles. Israeli engineers have also tested a stretch of what may turn into the road for future. The road contains piezoelectric crystal that creates power when pressed, empowering them to gather a portion of the energy which vehicles lose to the environment during their journey. The system is expected to deliver up to 400 kilowatts from a 1-kilometer stretch of the double carriageway. The technology is also applicable to airplane terminal runways and rail system (Schwartz, 2018). In addition, to produce its own power, the system can deliver real-time data on the weight, frequency, and speed of passing vehicles and the spacing between vehicles (Schwartz, 2018). Accordingly, the embedding of piezoelectric generators to make "smart road” could, in the long run, turn into a necessary part of traffic management system (Sharma et al., 2018). The Piezo Electric Generator created by Israeli University is increasing development for Parasitic Energy gathering (Sharma et al., 2018). The harvesting system of parasitic mechanical energy from roadways depends on the piezoelectric effect that converts mechanical strain into electrical current or voltage. The harvesting energy can be transferred back to the grid or utilised for specific road infrastructure. The infrastructure store energy for reuse (Shwartz, 2018). The generators are mounted with electronic cards providing the storage system. The laying of the present system, (installing the generators and electronic cards into the roadway), should be possible during paving of new roads or maintenance of existing roadways, so it's completely retrofit-table to any road. This implies that parasitic energy of busy roads, railways and runways can be converted into electrical energy that can be used for public electricity, or sustained back into the grid (Shwartz, 2018).

California model for Harvesting Energy

The California Energy Commission intends to find out how piezoelectric devices could turn road traffic into the dream of renewable energy. Energy harvesting methods have been growing in popularity lately in America. California has funded experiments on lot of traffic whereby roads which encounter substantial movement are fitted with piezoelectric transducers to convert the vibration produced by vehicles into electricity (Large.stanforededu, 2018). This electricity then is added into the grid to give energy to everything including buildings, homes, and road lights. Piezoelectric energy harvesting is not a new innovation. It's really been around for a time. In facts, energy harvesting has not exclusively been demonstrated. However, it is being used in a few sites (Large.stanforededu, 2018). For instance, a few prepare stations in Tokyo utilise piezoelectric energy to produce the power expected to run the ticket machines and electronic showcases (Du et al., 2017). Another model is a Dutch dance club which utilises piezoelectric tiles on the floor to control lights. Piezoelectric devices are more commonly used for generating sounds and measuring vibrations as opposed to generating electricity for energy consumption (Du et al., 2017). This makes finding energy data from piezoelectric energy harvesting rather difficult. However, there are currently transducers available that are specifically designed for generating electricity in energy harvesters. There are issues of costs of such a system. Piezo generators work in nightclubs and train stations since people are generally unlikely to destroy their pathways (Du et al., 2017). Since piezo devices rely upon deflection to deliver control, the trail needs to consider advancement and vibration to extend profitably of the collecting devices.

Roads must be built to restrict damage from tires and junk if they are to be secured and reliable (Du et al., 2017). As needs are, roads have a tendency to not move around and distort under impact. This makes putting transducers under roads dangerous on two fronts. Either the road is built to allow vibration imperativeness to accomplish the transducers which possibly makes the road weaker or the transducers don't achieve near their potential making them a costly investment (Schwartz, 2018). Furthermore, the world is moving from internal combustion engines to electric batteries. Combustion engines tend to vibrate even when they are stationary. Nevertheless, electric automobiles don't vibrate so much when stationary, thusly rendering the imperativeness gatherers less effective. This raises the issue of whether this piezo road will age with the expanding number of customers swinging to electric cars. In reality, California has apparently been the overall pioneer in the electric vehicle improvement beside China who competes aggressively for the electric car market.

Wireless System for Harvesting Energy

Wireless systems are becoming universal. It includes incorporated a wireless network based upon wireless availability of versatile gadgets and PC peripherals which utilise the Bluetooth standard. The utilisation of remote gadgets offers a few favorable circumstances over existing, wired systems (Chen et al., 2017). Its beneficial factor includes flexibility. However, the simplicity of wires is frequently a source of failure in such a system resulting in an extensive cost issue (Chen et al., 2017). At present, numerous wireless sensor hubs are battery controlled and work on economical budget. Efficient energy spending plan is required since consistent battery swap is not a possibility for systems with a huge number of physically inserted hubs. Besides, continuous battery replacement is not an option for networks with thousands of physically embedded nodes (Chen et al., 2017). Intelligence can also be used at the sensor hub to perform signal processing on the raw sensor data, execute interchange conventions and deal with the hub's power utilisation. These low-power wireless sensor hubs give a real incentive for elective sorts of intensity sources to conventional batteries. There are also solutions like smaller scale energy components and miniaturised scale turbine generators. Both the solutions include the utilisation of chemical energy and require fuelling when their supplies are depleted (Chen et al., 2017). Such systems are able to produce or generate large amounts of energy. They show great potential for the energising of, or notwithstanding supplanting, cell phone or workstation batteries (Chen et al., 2017). Renewable power can be acquired by creating electrical energy from light, warm and motor energy present inside the sensor. These sources can be utilised as either an immediate substitution or to expand the battery, in this manner increasing the lifetime and ability of the system and relieve the natural effect caused by issues encompassing the transfer of batteries. In this specific circumstance, solar based power is presumably the most well-known. Solar based cells offer phenomenal power density in coordinate sunlight. However, it is dependent on the surrounding light conditions and are plainly inadmissible in implanted applications where no light might be available, or where the cells can be obscured by contamination (Destek and Aslan, 2017). Thermal energy can be transduced into electrical energy using the Setback effect. Kinetic energy generators also convert energy through mechanical development present in the environment producing electrical energy. Kinetic energy is commonly present as vibrations, random displacements or forces and is regularly changed over into electrical energy utilising electromagnetic, piezoelectric or electrostatic components. Vibrations can be found in various applications including basic family merchandise (coolers, clothes washers and microwaves), mechanical plant gear, moving structures, such as vehicles and planes and structures, for example, structures and scaffolds (Destek and Aslan, 2017). The amount of generation by this methodology depends upon the amount and type of the kinetic energy available in the application environment, the efficiency of the generator and power conversion of the electronics (Destek and Aslan, 2017). The following section will discuss the essential soft kinetic energy harvesting and different mechanisms applied. This mechanism will then be illustrated by a comprehensive survey of generators created to date. There is a problem in using the field of vibration energy harvesting. With the predicted proliferation of wireless sensor networks, sufficient surrounding vibrations can help create an electrical supply by utilising a small scale generator to reap the mechanical excitation. There are three fundamental approaches that can be used to implement harvesting energy using wireless system (Chen et al., 2017).

Piezoelectric generators:

Piezoelectric generators offer the simplest methodology, whereby structure vibrations are directly converted into a voltage yield by utilising an electrode piezoelectric material (Shwartz, 2018). There is no necessity for having complex geometries and various extra segments. Piezoelectric generators are the most simple type of generator to manufacture and can be utilised in force and impact coupled harvesting applications (Shwartz, 2018). There is an extensive variety of piezoelectric materials available for various applications. Its advantages is that this transduction principle is particularly well suited to microengineering since several methods exist for saving piezoelectric films. The piezoelectric technique is equipped for creating generally high yield voltages however just at low electrical streams. Its transmission will be done with the wireless system. The piezoelectric materials require stress. Moreover, their mechanical properties allow large execution and a long lifetime (Shwartz, 2018).

Electromagnetic generators:

Electromagnetic generator offers a well-established technique of electrical power generation and the effect has been utilised for a long time in an assortment of electrical generators (Musa et al., 2018). Harvesting energy from roads and transmission is also done by the wireless system. High-performance bulk magnets, full-scale loops are promptly available. With Wafer-scales system, poor properties of planar magnets result in limitations on the number of turns achievable in addition to a limited amplitude of vibration (Musa et al., 2018).

Electrostatic generators

The electrostatic concepts are reliable and its working relies on the basis of the capacitor and storing of energy (de Queiroz, 2018). The energy source is the vibration taken from the road as well as its vehicle. The energy density of the generator can be increased by decreasing the capacitor spacing and encouraging scaling down. The energy density, in any case, is additionally diminished by decreasing the capacitor surface zone. High transduction damping, at low frequencies, is achievable by fusing small capacitor gap and high voltages (Musa et al., 2018). Shockingly, electrostatic generators require polarising voltage or charge. This is not an issue in applications that utilise the generator to charge a battery, as this can be utilised to give the vital introductory excitation level. Electrostatic generators can use electrets to give the underlying charge and these are fit for putting away charge for a long time. The transmission is done by the wireless system. The yield impedance of the gadgets is frequently very high and this makes them less suitable as a power supply. Capability requirements for custom circuit execution create difficult circuit designs. Parasitic capacitances within the structure can sometimes lead to reduced generator efficiency and there is a risk of capacitor anodes shorting or of 'stiction' in wafer-scale (Musa et al., 2018). The three primary techniques of harvesting energy from surrounding vibrations have become equipped for producing electricity. A few years ago, such energy levels would have been considered as 'unusable' (Musa et al., 2018). Advanced VLSI circuit plans work in light for low activity areas as well as many business areas. Circuits are now able to be applied or utilised in energy harvesting arrangements. The electronic calculator whose early frame required a few 'AA' measured cells, are currently capable of running completely off solar energy. Vibration-fueled remote sensor systems can also be utilised in various situations. Several research groups across the world are addressing possible applications of ambient intelligence, medical implants, and smart clothing (Chen et al., 2017). Wireless battery-less industrial condition monitoring system is about to commercialise in the market (Chen et al., 2017).

Discussion

Energy is the property of matter and radiation which is manifest as a capacity to perform work such as causing motion or the interaction of molecules (Gallagher et al., 2018). Our ability in performing a task or carrying out of particular works, manual or through external applications is essentially the result of energy. From simple walking to the switching on of lights, generation of electricity, the use of computers, air conditioners and the running of cars, planes, trains, and buses, all require energy to operate and function (Gallagher et al., 2018). As stated by Ritchie and Roser (2018) a key pillar to the wellbeing, poverty alleviation and economic development is our access to energy. The source, type, and application of energy have developed, evolved and advanced over time. Energy can be used for the production of electricity (Lu, Blakers and Stocks, 2017). There were many ways of energy production, from traditional to renewable and the costs associated are ever increasing. The production and utilisation of electricity is pivotal and very important throughout the world. With the associated and ever increasing costs in energy production and operation, there is also the question of energy efficiency and wastage. Where approximately 20% to 40% of fuel is actually utilised in the generation of the force in the movement of the vehicle a lot is wasted in friction, vibration, exhaust, heating and cooling. These wasted energy can be captured and utilised through energy harvesting. Harvesting energy is an innovative energy solution currently. Countries are shifting their energy sources into harvesting energy. The cost and natural reserve can also be saved (Xia and Shull, 2018). The focus of this thesis will be to explore the existing systems for harvesting energy (from around the world and Australia) and analysing how these technologies can be utilised to resolve energy wastage and inefficiency problems and challenges. The aim will be to identify applicable harvesting energy technologies that could potentially be utilised in Australia (mainly in Queensland) through public transportation systems. As detailed in this literature review there are currently research and works being carried out around the world in energy harvesting and there are technologies currently being tested and implemented accordingly.

Project Methodology

My thesis project is the carrying out and performance of a feasibility study in the field of energy harvesting technologies in public transport. My thesis project comprises of seven chapters. Chapter 1 is project background and significance, chapter 2 is literature review and project methodology, chapter 3 is current systems, chapter 4 is alternative solutions, chapter 5 is development and implementation of solutions, chapter 6 is cost benefit analysis and chapter 7 is conclusion and recommendation of future works. My project methodology will focus around the three main sections of literature review, main body and conclusion. In my literature review I have aimed at exploring and defining energy, energy harvesting, public transport in Australia and Queensland and the technologies currently and potentially available in the energy harvesting. This has provided a background to my thesis topic as well as potentially highlight the gap between energy harvesting technology and public transport. In my thesis main body I will identify the existing situation, all the existing large-scale energy harvesting technologies and their corresponding applications considering the context of applications. This will provide a better understanding of the entire appropriate energy harvesting technologies with regard to public transport systems. Moreover, I will identify those technologies suitable to Queensland’s situation, by comparing the working environment and conditions of each existing case. I will also be carrying out a cost-benefit analysis of the situations and scenarios in order to gain a better understanding and appreciation of the feasibility. I will also consider the technologies implementation easiness, the technology’s maturity, environmental protection, minimal interruption to the traffic during the implementation stage, and the operational and maintenance costs. Under the conclusion and recommended future works, I will do research and propose a portfolio of technologies for future investigations and. I will summaries my achievements throughout the project and highlight limitations or constraints so that I am able to propose future works in order to address those limitations or constraints, to come to an even better proposal for further development towards the realisation of adopting a novel large-scale energy harvesting system through public transportation in Queensland.

Chapter Three –Existing Public Transport System in Queensland

Queensland:

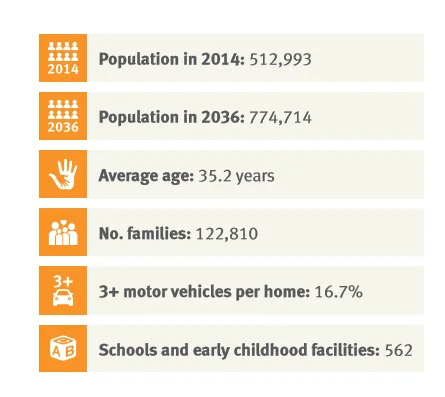

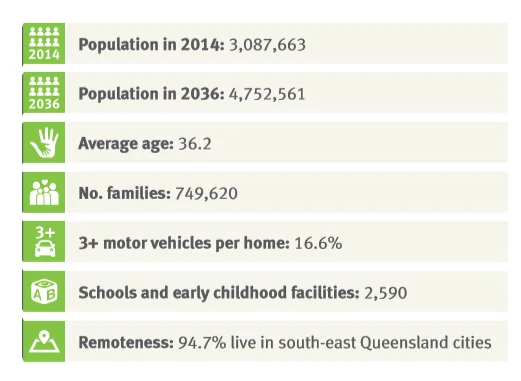

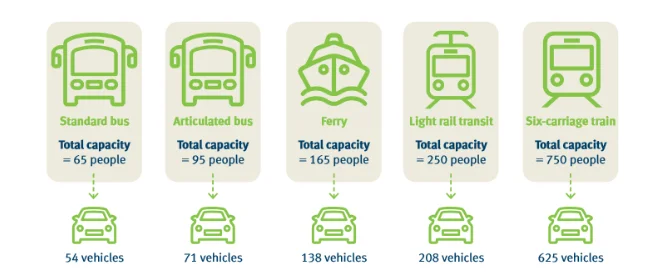

Queensland is the second-biggest and third-most populated state in the Australia. Queensland has a populace of 5,000,000 focused along the drift and especially in the state's South East (Fig 3.0). The capital and biggest city in the state is Brisbane, Australia's third-biggest city. Queensland is home to 10 of Australia's 30 most significant urban areas and is the country's third-biggest economy. Tourism in the state, fuelled to a great extent owing to its warm tropical atmosphere making it a unique industry (Abs.gov.au, 2018). There is more than 3.7 Million vehicles registered. There are three types of public transports that are used by people of Queensland which contains buses, trains, and ferries.

Public Transport in Queensland: