Latent Failures in Aviation Disasters

PART A

Q1

Failure is used to refer to the ultimate result of human error. In the aviation industry in particular, about 80% are due to human error (Chiu & Hsieh, 2016). Close to 20% are caused by maintenance errors. Typically, it is subdivided into active and latent failures. Major difference in the two is due to the length of time taken before consequence of human error is manifested as an accident. In the case of active errors, consequences are felt almost immediately. Latent errors pile up and add onto each other before they finally cause system lapse after a long period of time. In other terms, active failures are advanced by officials positioned at ‘sharp end’ of the aviation system (Saward & Stanton, 2015). They include air traffic control and pilots who directly control flow of the system. They handle the user-interface and any miss-step results immediate consequence, which may even be adverse depending on extent of failure triggered. Latent failure, is a more indirect form of error that is caused by decisions made by administration. These decisions impact design, well-being of personnel, guidelines and all related bureaucracies involved in running an aviation system (Reason, 2017). They may not be felt immediately and my take both time and combination with suitable trigger factors to compromise on system integrity.

The Swiss cheese model, also known as reason model is adopted to explain how and when perfect conditions for an accident come about. The holes in question only lead to an accident when all of them are aligned. It takes approach of a pilot that during operation, all contributing factors must be cooperated effectively. Since this model has four layers, it adopts four holes. They include; organizational influences, unsafe supervision, unsafe action and error and violation.

Organizational influences directly relates to management of resources in the aviation industry. Also involved are organizational processes and business environment around it. In poor resource management, an employee may opt to underestimate maintenance budget. This puts condition of the serviced plane in question. Unsafe supervision may include incorrect operation, poor supervision due to inadequacy of skills or time resources or outright supervisory infringement. Inadequate supervision coupled with poor resource management in the factor of organizational influences increase probability of occurrence of an accident (Chiu & Hsieh, 2016). Also, lack of emergency training on procedures for interns and new employees increases risk of accident. An unsafe action is another factor. However, it does not cause accidents directly. It is preceded by steps such as poor mental health, which in turn influences poor judgment and decisions. Note that these factors are important during analysis of an accident.

Latent failures, as stared before, are impacted greatly by decisions made by top level management. The factors forming backbone of this article are going to be discussed in three levels of evaluation. Also, note that latent failures are not always detected until much later and are not given center-stage in initial stages of investigation (Hooper & O’Hare, 2013). The first factor is the kind that has great bearing on any one or all of operator’s behavior. This may be termed as operator precondition and may span their wellbeing. They may be feeling unwell or be fatigued. For instance, on 12 February 2009, fast approaching the Buffalo-Niagara International Airport was a Colgan Air Bombardier DHC-8-400. Everyone on board and one person on the ground lost their lives after an accident. The airplane crashed as it neared the airport and about to land (Saward & Stanon, 2017). Thorough investigations reveal that all the pilots on duty had fatigue during that flight. This is proved by the fact that their conversation during the flight had nothing to do with the flight business. This alone showed little or no attention as result. This can be said to have had indirectly caused the accident. The second level that a sanctioned investigator will look at is precursors of plane crushes that are associated with latent failures or the threats themselves. Air France 447 plunged into the Atlantic Ocean back in 1 June 2009. 228 passengers on the plane died that day. Latent failure is seen by contracting the services of a novice pilot. His inexperience, according to the Blackbox Analysis, caused him to raise the nose way beyond the safe angle (Reason, 2017). This resulted in a stall of the plane propulsion system. Back to the four factors Swiss cheese is modeled around, this instance of allowing an inexperienced co-pilot can be classified as unsafe supervision on the case of superior authorities and unsafe actions on the part of the co-pilot.

The final step of latent failure investigation will mostly revolve around is evaluation of organizational failure. An airline may decide to increase net profit by reducing cost of operation, which may touch on pilot training. The airline may opt to reduce cost of training of pilots resulting in fewer pilots. Those who do not undergo the training are thus inexperienced. The case of Air France 447 that crashed into the Atlantic Ocean in 2009, can be used to explain why the co-pilot was not competent enough to know the nose lift limit range beyond which system stall would be initiated (Woods et al., 2017). All these three steeps in these orders are to be followed to ensure that causes of an accident are conclusively understood. Note that these steps highlight factors that precipitated such instances of aviation accidents. The Reason’s model, which is a contracted approach, could be expanded into local and organizational factors. Since they have been discussed in the model, they will be mentioned here. Local factors are those which are found in immediate place of work and they include; competence and experience, morale and incentives, availability of equipment and tools, well-being and fatigue, weather and environment and safety procedure among others. Organizational factors include; organizational structure of aviation system, quality training and selection process, proper planning and scheduling and proper communication system.

Looking for further insights on Key Decision Areas in the Aviation Industry? Click here.

There are certain recommendations that must be implemented to address problem of latent failures. While ascertaining absolute solution cannot be guaranteed, error-reduction and error-containment can be achieved. While maintaining the aircraft, the stakeholders in aviation industry can ensure that personnel selection is done such that merit is prioritized. Also, in Human resource management, the HR manager should ensure that well-being of staff is always taken into consideration so that they are not fatigued or thinned out during assignments. Pilots and air traffic controllers and flight engineers must by trained and retrained so that their knowledge is up to date with the current aviation industry. The licensing bodies must be evaluated continually to ensure that the quality of the certificates they award are quality and that the personnel they train are worth the papers they hold. This can be done by doing background checks on their training programs to evaluate their suitability. Adoption and improvement of Incident reporting systems ensures that errors in systems of airlines are instantly reported to an agreed sanctioning body for necessary guiding steps to be provided. Finally, the design engineers can be given more safety guideline recommendations during the design phase so that they may be incorporated. It is always best to take care of impending danger during design stage. In summary, Latent failures are a buildup of a series of errors in the past, which take time to cause; and accident. They are different from active failures, which cause immediate lapse in aviation systems. This article has approached latent failures causality factors with the Reason’s model. It further touches on local and organizational factors as constituent elements of the four factors. Finally, some recommendations are made to help avert some of these failures.

Q2

There is an increasing concern about the misuse of drug and alcohol and the impact it has on performance and workplace safety, especially the construction industry. While drug and alcohol misuse has been largely considered as a safety-critical issue, there is insufficient information in regard to its prevalence (Hinze et al., 2013). Notably, there is unsubstantial guidance outlined to help in curbing the issue. This paper aims at providing a program that can be employed by the construction company to assist in addressing this issue or rather reducing it to a tolerable level. First, this paper will start by providing a summary of the impacts of alcohol and drug misuse to the workers, particularly on the construction site before embarking on program test for drug and alcohol misuse at workplace.

Lack of concentration, impaired judgment, and other unforeseen side effects of drug and alcohol misuse by the workers are more likely to result in increased accidents, fatalities and injuries at the workplace. BLUM et al (2015), establishes that one-fifth of managers and workers have complained that the persistent drinking habits of their colleagues hamper and jeopardize their productivity and safety. According to Garrringer (2015), the highly witnessed third drastic rise in workplace violence is caused by drug and alcohol misuse. The victims are three times more likely to be injured especially in a construction site that has dangerous equipment and located in accident arable area. Employees who misuse the drug are three times more likely to encounter outside workplace injuries as compared to workers who do not misuse or use the drugs. In most cases, the workers tend to fall asleep during working hours. They are likely to focus much of their attention on using or obtaining the drug at the workplace as such, they suffer injuries of lost-time (Biggs & Williamson, 2012). Additionally, the workers tend to move from one job to the other. This is costly to the employer owing to the fact that he or she will spend a lot of time interviewing and training new workers. Secondly, Drug and alcohol misuse reduces the morale of the workers involved. The behavior of an individual suddenly changes which in turn reduces the morale, for instance, the abusers may be quick-tempered, tardy or defensive (Hinze et al., 2012). They may get depressed due to financial constraints and sometimes heap blames on their colleagues for their own mistakes. Notably, one affected worker is capable of diminishing the morale of the entire workplace. Coworkers may get frustrated when trying to cover up duties neglected by the substance abuser thus making some of them to quit their job (BLUM et al., 2012). Other impacts include theft and damage of property, compensation of workers, legal liabilities, premature death, and higher cost of health care.

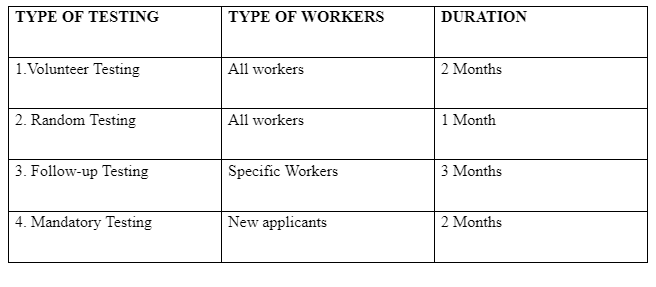

Introducing drug and alcohol safety program test to the works may be challenging, the fact that some employees may find it difficult to avail themselves to undergo the process for the fear of being dismissed from the workplace, as such, some workers may be reluctant to embrace the program. In order to counter this, the company will first initiate and implement drug free policies and rules in relation to the set program that every worker must comply with. Additionally, the company will issue notices to all workers to inform them about the current program that the company is planning to implement. Notably, the notices will bear the grave consequences that are likely to hit the company shall the problem go unresolved. The workers will be allowed to freely have their say concerning the program and even to present any legal document supporting the use of any given drug. The company will also make efforts to justify to the employees reasons as to why the program is necessary especially when a serious risk of damage is likely to be encountered. The fact that the company understand the signs of alcohol and drug misuse, it will apply this understanding to have a cutting edge on programs to be employed in order to eliminate or minimize the usage to a tolerable level. The company will use this short scheme to conduct the test to all its workers.

Drug and Alcohol testing program

The objective of this testing program is to assist the company to step up its level of productivity and also to provide an enabling environment that will be able to secure the safety of all workers at the workplace thus essence of their efforts can be realized. The testing programs are discussed below.

The urine drug testing

This is the most technologically advanced testing method that would be appropriate for the company. This method is used to provide a detailed analysis of the worker's urine. It screens the urine of specific use of illicit drug. The most common drugs screened are cocaine, opioids, PCP, marijuana, amphetamines and barbiturates. There are two types of urine drug test; however, dip cards urine drug test will be given preference due to its simplicity in administering, and the fact that it does not require specialized training (Biggs & Williamson, 2012).

Saliva testing

This test will be used to collect saliva inside the mouth of workers. The saliva will then be tested to find out whether the worker is using illegal drugs. It should be noted that this test can detect usage of the drug within the past few days. The test is used to detect the use of cocaine, methamphetamines, alcohol, and marijuana. The saliva test is a common test program applied by many employers to check for the illegal use of drugs among the employees. Its prevalence usage is due to the fact that it is cheap and easy to administer as compared to other testing programs (Dunlap, 2012). It is easy to collect saliva from the workers and test. The test can often be carried out on-site thus it is fast and efficient.

Hair drug test

This test is also referred to as hair follicle drug test. It used to screen prescription medication misuse and illicit drug. While carrying out the test, a small amount of hair should be removed from workers head using a scissor. The obtained sample is then put under analysis for any sign of drug use for the last 90 days (Garringer et al., 2015). This test will be applied to test for the usage of cocaine, marijuana, ecstasy, PCP, amphetamine and opioids.

Breath alcohol test

This test will be applied by the company to test for the level of alcohol a worker has consumed. The device make use of measurement to find out the estimate of alcohol content present in the blood. The number is referred to as the BAC. The alcohol content is likely to rise up after fifteen minutes of drinking and steadily move higher after about an hour. As the BAC of an individual rises up, the person gets clumsy and may not react promptly, as such, there is a likelihood of making wrong choices that are consider non grata at the workplace and the company in general.

Q3

Occupational carcinogens are defined as biological or chemical agents which human beings are exposed to or come into contact with in occupational settings (Chappell et al., 2016). Occupational settings are related to places of work where people get their economic income. For the purposes of this paper, construction sites are taken into consideration. The given extent of exposure workers face is related to type or nature of job they do and mitigating measures taken to limit it. Also, of significance for this paper is to comprehend that the probability that these workers get cancer afterwards is directly influenced by dosage of carcinogens they have taken, how potent they are, tolerance of each worker and availability of other forms of aiding exposures. This article is done to identify carcinogenic hazards in construction sites and come up with recommendations to abate exposure during construction phase. Finally, exposure limit below which safety is guaranteed for the workers is discussed.

Specific carcinogenic hazards include;

Working with Wood Dust

Members of staff who are tasked with shaping wood for fitting purposes may consume a lot of wood dust through inhalation, which is unhealthy. Wood Dust is produced in high quantities when shaping, cutting tools or machines used. Examples of activities that require such input are carpentry and cabinet designing. Wood Dust is inhaled and trapped in many places along the airway. Occupations that involve great exposure to this carcinogen may involve sander and press operators in transport equipment and wood products industries respectively (Carey et al., 2014). Other operators include the lathe machine in wood item production and sander in wooden cabinets. Tse et al (2011) denotes that Studies that focused on occupations involving experts with high exposure to wood- dust showed consistency with cancers of nasal cavity. Other cancers that had strong relationships with this occupational carcinogen is that of the paranasal sinuses.

Recommendations

The high exposure involved with this occupation can be lowered by designing and implementing structural changes to the production setups to include exhaust ventilation systems. The systems should be fitted with collectors at point of wood dust production. Other temporary solutions such as equipping personnel with protective gears like respirators can be adopted.

Concrete work

Concrete is made up of cement, rock, water, and sand. Cement, among other chemical compounds is made up of calcium compounds. The need to achieve a given quality of concrete setting may drive staff to use carcinogenic components such as asbestos. Note however that the use of this specific compound had been greatly dropped for better alternatives. Regulations have played an active role in ensuring this (Cherrie et al., 2017). Otherwise, concrete may be made up of granite aggregates or radon gas, which may find a suitable way of getting attached to the concrete. Production process of cement has been known not to get rid of all contaminants such as Hexavalent chromate, which is known to cause lung cancer. Other known carcinogens found in concrete include chromium and silica. Borrowing a special practice in Sweden, the risk of chromium eczema has made it compulsory for incorporation of ferric chloride. This practice has been carried for about 4 decades (Loomis et al., 2018).

Recommendations

It is advisable to ensure that as little cement dust as possible is produced in the construction sites as possible. Headway had been made by adoption of readily mixed concrete transported to sites using Lorries designed with rotating drums in recent change of job tasks in the industry. This can be interpreted as reduction of cement exposure. It advisable to continue with the same spirit and that research on better ways to reduce exposure even further be done.

Welding and welding fumes

Studies in the recent past have shown carcinogenicity of welding fumes. Roles of a combination of smoking, asbestos, and welding fumes have been studied to the point of establishing that smoking is more potent when associated with small and squamous cell carcinoma. Asbestos as an occupational carcinogenic has been strongly associated with adenocarcinoma. Other agents include inorganic lead has been widely linked to cancers of brain, kidney, nervous system and stomach. Nickel on the other hand is a proven carcinogen for nasal and lung cancers. Also linked with lung cancer is exposure to cadmium (De Matteis et al., 2012). Exposure to UV radiation has been found to be linked with ocular melanoma in a 2012 IARC report. Both mesothelioma and wide occurrence of lung cancer cases among welders has been attributed to the wide usage of asbestos material in production of welding instruments.

Recommendations

Level of exposure to carcinogens can be reduced to probability of developing cancer. For the case of UV radiation, welders are advice to maintain safe distance during operation. Also, they could limit one-time period of exposure by doing short rounds of welding to complete a given task. Always use welding methods that produce little fumes. One can change power settings to achieve this. Welders should request installation of artificial dilution ventilation and local exhaust to limit fumes concentration. Also, they could wear protective gears that purify air breathed or supply air. The coordinator should ensure that welders and other workers are always working separately to limit their exposure to fumes.

Refueling of automotive machine on site

According to Labreche et al (2013), when inhaled, pollutants like Volatile organic compounds (VOCs) have negative impact on human body. Of specific interest is the benzene, toluene, ethylbenzene and the three isomers of xylene (BTEX) group. It does not matter how it gains access into the body because effect is the same. The potency of this group is underscored by a study, which put forward that about half of volume of this compound inhaled into a human body actually absorbed. It further stated that suppose 1 million people are exposed to 1 mg/m3 of benzene, 4 are have a high risk of getting cancer of the blood (Chappel et al., 2016). Given the wide range of heavy machine that consume a lot of diesel, refill puts the attendants and other staff working nearby at risk of getting leukemia when they inhale the fumes. Also, mechanics are at a high risk of getting cancer during repair of automobiles.

Recommendations

Improvement of mechanical and natural ventilation systems fuel bays is important. For this scenario, the coordinator can ensure that refueling is not done near other staff. Apart from fuel bays, safety of company repair mechanics must be guaranteed by ensuring that their workshops are adequately ventilated.

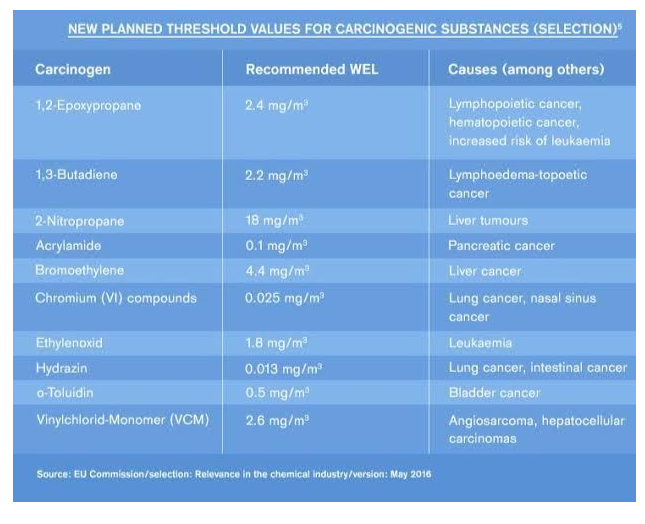

Exposure limit

Note: Legally, no person must be held in such environment. Exceeding such limits predisposes one to cancer. Standard periods in which most of these limits are expressed is 15 minutes and 8 hours or any other appropriate limit. In conclusion, Workers exposed to wood dust have high chance of getting cancer of nasal cavity and paranasal sinuses. Those working in concrete are exposed to Hexavalent chromate, which causes lung cancer. Welding fumes are quite potent and affect everyone working near them. This is why it is important to separate welders from other members of staff. Finally, effect of BTEX is discussed noting how they can cause leukemia. Recommendations are made for every hazard.

Q4

Local exhaust ventilation refers to an engineering system that is often applied in the workplace in order to shield employees from different forms of hazards (Leman et al., 2016). Designing and installation of an effective system is important to reduce the risk of exposure. It is a fact that frequent exposure to occupational hazards such as vapours, dust and fumes can greatly attribute to bad health among workers. The impact of exposure is mainly drawn from duration, degree and frequency of exposure (Hu & Yi, 2016). There are quite a number of LEV systems and this depends on needs: small enclosure, walk-in booth, capturing hood, receiving hood, down-flow booth, a partial enclosure and total enclosure. Before recommending an appropriate system, it is important to bring forth question that has bearing on factors to be looked into details while installing and commissioning the LEV system. What are the criteria to be considered when selecting or recommending an appropriate LEV system? It is important to note that the selected LEV system must be fit for the purpose. For this case, the process will entail grinding where the emission of dust coming from the wood will be expected, as such, the appropriate system should be in a position to capture or contain moving dust. Capturing hood is considered ideal and fit for the purpose thus.

Factors to be considered while design, installation and commissioning of the LEV system

Before designing and commissioning the LEV system, it would be imperative to consider a number of factors that plays a significant role in effective operation of the system: The need to adapt the system to conform to the changing processes and materials, is the system required to be adaptable and flexible, simple or complex? Firstly, there is a need to draw up a specification for the review of the employer. The specification should give regard to the processes of work, the involved employees, the potential fugitive dust and exposure points or sources. It is essential that all points of exposure are identified to enable accuracy in the specification as well as to avoid costly retrofitting (Ahmed & Kareem, 2017). An extensive and rigorous evaluation of risk conducted initially while identifying those areas where controlled is required is important since it facilitates an effective installation of the system. In designing an ideal system, there is a need to consider every element as well as integrating every element into the system. Notably, it is not recommended designing the system in isolation (Weinstein et al., 2016). Other essential specifications to consider are: Whether there is any other system of ventilation put in place, whether there is exhaust ventilation or controlled supply, whether the area have natural ventilation through windows and doors. It should be noted that the current conditions such as the consistent movement of air, droughts, or lack of control will adversely affect the LEV performance (Lee et al., 2018).

The type and sources of the contaminant will determine the type of enclosure or hood required. For instance, the contaminant can be directional (grinding), buoyant, propelled or injected into moving air. The size of the ducting must be accurate in order to facilitate the movement of the contaminant to the filter and point of the discharging points (Leman et al., 2016). Suppose the ducting has a multi-point, is there need to design the system to operate all points or rather a given percentage of points of exhaust at every one time? How will the control be done? The discharge will take into consideration the needs for a particular exhaust plume and the area unique topography in order to ensure exhaust air re-entrainment into supply air is not witnessed. Kokkonen et al (2019), denotes that specifications should make it easier and safer to check out, clean and maintain the LEV system. There would be need to record the performance rate of the system, the performance instrument indicator is installed thus. Once specification of the LEV system is completed, commissioning and installation commence immediately. According to Weinstein et al (2016), when installing the LEV system, it is important to use a reputable and experienced supplier who has a good understanding and ability to provide a detailed explanation that the system will be in a position to satisfactorily control potential contaminants. The LEV supplier should be in a position to issue out a user manual that contains a detailed description regarding what the LEV system is designed to control and the manner in which it should achieve such controls. The manual description should also contain a list of all replaceable parts, the previous performance obtained from commissioning, control failure, and signs of wear to monitor, checks and parts replacement schedule and the description showing ways in which the operators are supposed to apply LEV, in order to enable it to operate effectively. In the construction and installation phase, there are also a number of important questions that should be considered in order to set up an effective installation of the LEV system. Will the process of fabrication conducted on-site? Will the installation affect the major areas of the premises? The system is installed taking hid to all factors outlined in the specification of the LEV system to be installed (Lee et al., 2018).

Once installed the process of commissioning the system is started. This process provides enough control and adequate working to design. The process of commissioning must consider factors such as the work practices and 'hardware' of the LEV system suppose it is a true measure of performance. While commissioning the system, it is important to make a range of measurements. The type and number is determined by the complexity of the system and design of the hood. If the process discharges out particles. A dust lamp is applied to prevent the dust from reaching the workers. Notably, this technique doesn't need a surrogate to observe the movement of air (Hu & Yi, 2016). Additionally, it is important to check the elements of the commissioning process which implies the physical observation carried out on the integrity of the system: Is the system properly sealed or undone at some parts? Is the system fabricated by the use of right materials? Has the system been correctly assembled in regard to the plans and drawings? The rates of air-flow at every hood must be thoroughly checked while conducting the physical checks. Notably, when the system is multi-branched, the flows of air must be balanced by the use of sliding dampers or in-line blast gates (Huang et al., 2015). The effectiveness of control should be verified at this point. Quantitative and qualitative should be checked in order to verify the operation of the system and criteria of the design. It is important that the operators get the insight of the system operation (Leman et al., 2016). Once the system is commissioned and all factors in regard to appropriate commissioning of the system are all checked, the completed data are set from designing to commissioning. The data is handed over to the employer in form of user manual, which is regarded as an aspect of design, installation, and commissioning process.

References

- Ahmed, A. Q., Gao, S., & Kareem, A. K. (2017). Energy saving and indoor thermal comfort evaluation using a novel local exhaust ventilation system for office rooms. Applied Thermal Engineering, 110, 821-834.

- Biggs, H. C., & Williamson, A. (2012). Safety impacts of alcohol and other drugs in the construction industry: A research methodology. In Proceedings of the 1st International Conference on Safety and Crisis Management in the Construction, Tourism and SMEs Sectors (pp. 364-376). Brown Walker Press.

- Biggs, H. C., & Williamson, A. R. (2012, September). Safety impacts of alcohol and other drugs in construction: Development of an industry policy and cultural change management program. In ARCOM Proceedings of the 28th Annual Conference (Vol. 1, pp. 445-454). Association of Researchers in Construction Management (ARCOM).

- Blum, T. C., Fields, D. L., & Milne, S. H. (2012). The Interrelations of Drug Testing with Other Human Resource Management Practices and Organizational. Drug Testing in the Workplace, 11, 279.

- Carey, R. N., Driscoll, T. R., Peters, S., Glass, D. C., Reid, A., Benke, G., & Fritschi, L. (2014). Estimated prevalence of exposure to occupational carcinogens in Australia (2011–2012). Occup Environ Med, 71(1), 55.

- Chappell, G., Pogribny, I. P., Guyton, K. Z., & Rusyn, I. (2016). Epigenetic alterations induced by genotoxic occupational and environmental human chemical carcinogens: a systematic literature review. Mutation Research/Reviews in Mutation Research, 768, 27-45.

- Cherrie, J. W., Hutchings, S., Ng, M. G., Mistry, R., Corden, C., Lamb, J., ... & Rushton, L. (2017). Prioritising action on occupational carcinogens in Europe: a socioeconomic and health impact assessment. British journal of cancer, 117(2), 274.

- Chiu, M. C., & Hsieh, M. C. (2016). Latent human error analysis and efficient improvement strategies by fuzzy TOPSIS in aviation maintenance tasks. Applied ergonomics, 54, 136- 147.

- De Matteis, S., Consonni, D., Lubin, J. H., Tucker, M., Peters, S., Vermeulen, R. C. ... & Wacholder, S. (2012). Impact of occupational carcinogens on lung cancer risk in a general population. International journal of epidemiology, 41(3), 711-721.

- Hinze, J., Hallowell, M., & Baud, K. (2013). Construction-safety best practices and relationships to safety performance. Journal of construction engineering and management, 139(10), 04013006.

- Huang, Y., Wang, Y., Liu, L., Nielsen, P. V., Jensen, R. L., & Yan, F. (2015). Reduced-scale experimental investigation on ventilation performance of a local exhaust hood in an industrial plant. Building and Environment, 85, 94-103.

- Kohneshahri, M. H., Mohammadyan, M., Khani, H. M., Pourhossein, M., & Dastakzan, B. (2016). Designing a Local Exhaust Ventilation System to Control Toluene Diisocyanate and Dust in Woodworking Industries. International Journal of Occupational Hygiene, 8(4), 223-229.

- Kokkonen, A., Linnainmaa, M., Säämänen, A., Kanerva, T., Sorvari, J., Kolehmainen, M., ... & Pasanen, P. (2019). Control of Dust Dispersion From an Enclosed Renovation Site Into Adjacent Areas by Using Local Exhaust Ventilation. Annals of work exposures and health, 63(4), 468-479.

- Labrèche, F., Duguay, P., Ostiguy, C., Boucher, A., Roberge, B., Peters, C. E., & Demers, P. A. (2013). Estimating occupational exposure to carcinogens in Quebec. American journal of industrial medicine, 56(9), 1040-1050.

- Lee, T., Soo, J. C., LeBouf, R. F., Burns, D., Schwegler-Berry, D., Kashon, M., ... & Harper, M. (2018). Surgical smoke control with local exhaust ventilation: Experimental study. Journal of occupational and environmental hygiene, 15(4), 341-350.

- Leman, A. M., Zakaria, S., Jamaludin, M. F. Z., Nazri, A. A., Rahman, K. A., & Feriyanto, D. (2016). Air Velocity Flow Analysis Of Local Exhaust Ventilation (LEV). Journal of Occupational Safety and Health, 13(1).

- Loomis, D., Guha, N., Hall, A. L., & Straif, K. (2018). Identifying occupational carcinogens: an update from the IARC Monographs. Occupational and environmental medicine, 75(8), 593-603.

- Practice for Mentoring [TM]: Research-Informed and Practitioner-Approved Best Practices for Creating and Sustaining Impactful Mentoring Relationships and Strong Program Services. MENTOR: National Mentoring Partnership.

- Reason, J. (2017). The contribution of latent human failures to the breakdown of complex systems. In Human Error in Aviation (pp. 5-14). Routledge.

- Saward, J. R., & Stanton, N. A. (2015). Individual latent error detection and recovery in naval aircraft maintenance: introducing a proposal linking schema theory with a multi-process approach to human error research. Theoretical Issues in Ergonomics Science, 16(3), 255- 272.

- Saward, J. R., & Stanton, N. A. (2017). Latent error detection: A golden two hours for detection. Applied ergonomics, 59, 104-113.

- Tse, L. A., Yu, I. S., Au, J. S. K., Qiu, H., & Wang, X. R. (2011). Silica dust, diesel exhaust, and painting work are the significant occupational risk factors for lung cancer in nonsmoking Chinese men. British journal of cancer, 104(1), 208.

- Weinstein, M., Susi, P., & Goldberg, M. (2016). The power of local action in occupational health: the adoption of local exhaust ventilation in the Chicago tuckpointing trade. International journal of occupational and environmental health, 22(2), 142-150.

- Wiegmann, D. A., & Shappell, S. A. (2017). A human error approach to aviation accident analysis: The human factors analysis and classification system. Routledge.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts