Lean Manufacturing at Toyota

Introduction:

The success of Toyota depends on the operational principles and means management technique, where the organisation creates decentralised structure to empower the employees and engage them in the operational activities (Aoki and Wilhelm, 2017). It is successful to gain competitive advantage in the global automobile marketing and lead manufacturing philosophy is the major success factor of Toyota. Toyota’s production system is based on the lean manufacturing philosophy which includes product design, customer relation, supplier network management and operations, through which Toyota tries to expand their business and manage strong operational activities in the market (Ichinose et al., 2018). The profitability of the company is maximised over the period of time, where the strategies of supply chain management as well as inventory management leads the firm towards efficiency and productivity.

Toyota’s principle of operation management

The organisation Toyota focuses on developing operational principles for managing their activities and ensuring that the products are in good quality with latest design and additional technological innovations (Chiarini, Baccarani and Mascherpa, 2018). Designing the goods and services is the major operational principle, here the company aims at conduct Research and Development as well as invest in market research for understanding the customer’s requirements. This further boosts the organisational decision making practice where Toyota is successful to create high quality cars for the benefits of the customers. The advanced features as well as innovative design of the cars further create values for the customers in long run.

Process and capacity design is another principle, through which Toyota tries to reduce the waste and increase efficiency for manufacturing the quality products. The quality management principle is also good for the organisation to improve their operations and ensure high quality product delivery. Location strategy for localised manufacturing plant development is also another principle, where Toyota aims at manage their production unit and maintain the stock of raw materials efficiently (Coetzee et al., 2016). Additionally, scheduling and maintenance of the production sites are effective to continuously improve the operational efficiency and ensure that the company provides high quality products with latest design and technological innovations.

Human resource management and supply chain are other tow operational principles to make the business successful where Toyota focuses on job design, sharing clear role and responsibilities of staff members in the production units, managing all the individuals engaged with the production and operations (Kawamoto et al., 2017). The company is also efficient to manage their supply chain in order to maintain strong bonding with the suppliers and retain them for long run. Supply chain management includes lean management, automation process for real time adjustment in the supply chain activities so that Toyota would be able to minimise the cost and time of the operations and maximise its efficiency to serve the customers in the market.

Six Sigma method and Lean Principles at Toyota

Toyota’s success factors are the TPS system where Kaizen is the technique through which the whole process is controlled and monitored. The organisation tries to manage their operations and production activities through Japanese reduction tactics (Toma, and Naruo, 2017). JIT production system is also implemented in the organisation for managing the production of quality products in the organisation. Incorporated total quality control, statistical process control and quality circles are also effective for the organisation to respond the demand for their products.

TPS is highly flexible and efficient for managing the production and manufacturing activities of Toyota manufacturing activities and reducing high quality automobile products in the market. The Kanban system is also effective in Toyota, where Kanban synchronises the production system and maintain the units if produced products efficiently. The IT system is also handled efficiently which includes Enterprise Resource Planning (ERP) (Suh, 2017).

Characteristics of TPS

The organisation Toyota is successful to manage their production unit by JIT and Jidoka system, where the organisation can reduce the cost of the production by managing their raw materials, inventory and pull strategy of production. Just in time strategy is effective to manage the stock of the raw materials and it further fasters the production activities in the manufacturing unit. The organisation is also efficient to maintain the quality of the products and ensure high efficiency in serving the customers (Gerard, Chiu and Shilagani, 2020).

Just In time

Kanban system is implemented to manage Just in time in Toyota where overproduction is managed well to reduce the wastage and cost of operations. Waste minimisation and defect prevention system are effective for Toyota to maximise the quality of their products. The work in progress and the raw materials required for production are managed well through the system. JIT also controls the delivery and necessary quantities of operations in the company.

Lean manufacturing

Toyota lean management principles are effective for the organisation to manage the quality of production and solve the problems arises in the production process. The leader of the organisation encourages team working activities for better quality management and improving the production process. Toyota introduces the flat structure of production to facilitate experiments and learning through high communication (Gerard, Chiu and Shilagani, 2020). The organisation also seeks new method of working in the production units for better performance and manufacturing a large volume of automobile products. The lean philosophy of Toyota also incorporates JIT system and Kanban for better management and developing integrated system of production.

The organisation is successful to manage their operations through lean management principles, where the Kanban system and JIT are effective to manage inventory control as well as lower the cost of operations. The structured flow and production activities are controlled under proper monitoring and managing the flow of raw materials, where the inventory are managed well in the production sites of Toyota. Six sigma principles of reducing the error, cost, time and defects in the prediction activities are effective in Toyota, where the lean management and technological innovation support the manufacturing units to control their time and cost of production and produce high quality products.

Conclusion

The organisational activities are efficient to manage their production and the strategy of just in time and operational principles are beneficial for the firm to manage their manufacturing unit and design high quality automobile products efficiently in the market to manage the customers in long run.

Applying the concept of continuous improvement in an operational context

Introduction

For successful operational excellence and enhancing the performance of the organisation, continuous improvement lean is mandatory for the multinational corporation to develop creative strategic planning so that it would be beneficial for the firm to achieve future success. This part is helpful for developing continuous improvement lean in order to make the productions and operational system efficient. The continuous development lean is for Toyota, which is a famous automobile manufacturing organisational across the globe. The organisation is known for this efficient production and operations and it is successful to deliver high quality cars to the customers across the international borders. The continuous improvement model is good for the organisation to support the production and operational activities and create a good lean for better management.

Continuous improvement plan

The organisation Toyota mainly focuses on JIT and Jidoka for managing the operational activities and it is beneficial for the firm to achieve future success as the production process of Toyota is efficient to maximise the quality of the final output and serve the customers in a better and unique way. The technical team of Toyota is efficient to manage the technical activities and improve their production process further. However, the organisation must implement ERP system in all the production sites and manage the integrated system for better efficiency and maximising its quality (Gerard, Chiu and Shilagani, 2020). ERP is the integrated process, where the products and manufacturing activities as well as operational activities are handled within effective time. The automated process of operation and production are effective for the organisation where Toyota would be able to maintain its big data and analyse the system efficiently. The organisation should focus on asset management and arrange the raw materials for smooth production pace. Additionally, the organisation also must aim at financial planning, big data analysis under the ERP system in order to manage the operations efficiently. The inventory control system, online data management for racking the inventory and raw materials would also be effective planning for Toyota to improve its efficiency in handling the stick of the raw materials and enhance pull strategy (Iwao, 2017).

In addition to this, the organisation must focus on human resource management for continuous improvement and in this regard arranging technical training program and developing partnership working practice are mandatory for the organisation to engage the staff members and give them the opportunity for personal and professional development (Monden, 2019). In addition to this, the organisation needs to develop performance related pay and incentive structure for encouraging the staff members and technicians for better management and improving the system continuously. Leadership practice must also be improved in the organisation, where the leader of Toyota needs to provide continuous support, share the important information of the organisation and direct them efficiently to improve their performance. The organisation needs to develop customer centred services to engage the customers 24*7 and create values for them and in this regard the ERP system is an integrated system which also allows Toyota to manage their customers worldwide. These are the major planning for continuous improvement of Toyotas operational activities.

Justifying strategies for continuous improvement at Toyota

The above mentioned continuous improvement plan is effective for Toyota in creating values for the customers, as the activities according to the plan further helps the employees to improve their experience and capabilities to perform better in the production sites. The operational excellence can be maximised through the plan where the suppliers and the employees become coordinated for performing as a partnership working practice (Fujimoto et al., 2019). This further helps the brand to improve their operations and manage the worldwide supply chain efficiently. The lean management principles can also be improved through the above mentioned plan, where the employees get the scope for empowering themselves and make creative decision for managing their production units. The planning are effective hereby where Toyota has the chance to maximise efficiency and run their production sites more innovatively through latest organisational IT infrastructure and the ERP system which further boosts the TPS including Just in time and Jidoka strategy.

Conclusion

It can be concluded that, the continuous development plan for Toyota is beneficial for the organisation to reduce the time of operations and maximise the efficiency of the employees and technicians to support the production units. The inventory management system through lean principles can also be developed where Toyota would be able to maximise their quality in maintaining the operational activities in the market. Toyota also can improve their services towards the customers and this further provides a scope to create positive branding in the market.

Case 2: Renovation of leisure centres of Paul and Penny

Introduction

Project management is a critical activity where there project managers and the operational head try to collaborate and communicate about the project and select suitable steps to develop the tasks so that the major aim of the project can be achieved and in this regard the activities such as capital investment, recruiting experienced staff, communication plan, work break down structure, identifying the project aim and deliverables as well as the financial planning, Gantt chart development and monitoring and control of the project are necessary for successful completion of the organisational objects. Paul and Penny is an established organisation working in the leisure industry. The business is successful in expanding their operations worldwide and the entrepreneurs and management team are proficient to handle the leisure activities and design the services for the customers. The organisation Paul and Penny has their business in Clapham and it is able to restructure new destinations for retaining more long run visitors and travellers for enjoying their leisure time. The project life cycle model in this regard is effective for the organisation Paul and Penny to renovate their locations and expand the business internationally to represent their services in the global leisure industry so that Paul and Penny can ensure future sustainable development as well and maximise their organisational objectives in long run. The organisation is an able to be financially stable and invest a lump sum amount of capital for the successful establishment of the project. In this regard, the project life cycle model gives the scope to restructure the operations of the Paul and Penny and manage their activities to establish and renovate the new place. The new destination, chosen by Paul and Penny is Croydon. The study is hereby effective to implement the project life cycle model and evaluate the activities and operations of the organisation Paul and Penny so that it would be possible for the firm to renovate the new destination at Croydon and attract the customers for enjoying their leisure time. The steps of project life cycle model are effective for the organisation Paul and Penny to follow the strategies and arrange the resources and maximise capabilities of the employees so that the managers and staff members can renovate the place and complete the project efficiently.

Applying the Project Life Cycle to a given context

Managing the project and creating a good project planning can be easier by selecting the steps of the project life cycle model which further helps the organisation, where the project management team can work collaboratively and develop suitable planning for fulfilling the business values (Medeiros et al., 2018). Paul and Penny are targets to develop new leisure activities at new destination Croydon by renovating the place with high quality services and facilities. In this regard effective investment as well as project planning is mandatory for the organisation Paul and Penny are to complete the project and make the business successful.

Project initiation and conception

Project objectives:

The objective of the project is to expand the business of Paul and Penny by introducing attractive place Croydon with all the leisure services available of the customers. Paul and Penny try to establish the business in the leisure centres and gain high competitive advantage across the global tourism industry. Through the project, it would be possible to expand the operations of Paul and Penny to Croydon and renovate the place for attracting the customers in long run. The project is beneficial for the Paul and Penny to establish the business more innovatively with high quality services, additional facilities at the place and leisure services available for the customers.

Project scope:

The major scopes of the project are such as,

Maximising leisure activities of the organisation Paul and Penny

Attracting long term and trustworthy customers for enjoying their leisure time

Introducing additional facilities at the place Croydon

Launching the latest information technology and innovative services at the pace

Successful expansion of the brand Paul and Penny to Croydon

Ensuring first class and luxury facilities for the customers

Making the place attractive with new service innovations

Making the business profitable in long run

Project planning

Budget planning

Work break down structure for this project

Launch and execution

For launching the project and executing it with successful plan, it is mandatory to reallocate the resources, available for the project (Shi, 2019). The major resources of the organisation Paul and Penny are human resource, technology, capital and organisational infrastructure. The organisation Paul and Penny is efficient to invest appropriate capital required for the project. The estimated cost for the project is £2 million and it is effective for the Paul and Penny to invest and progress in the project. In addition to this, the organisational infrastructure is good where the ICT framework, the arrangements of the meetings and growing working activities are also effective where the project managers and the employees can get suitable workplace for progressing in the project at Croydon. Paul and Penny also focus on recruiting the experienced staff members as human resource is mandatory for successful completion of the project. In this regard, the recruited staff and employees in the project team are efficient, and there are experienced interior decorators, service management officer in hospitality industry, plumber and painters, raw materials suppliers of designing the place as well as the project managers who are beneficial to launch and execute the project and complete it successfully.

Project deliverables

The project deliverables need to be developed to understand the performance of the Paul and Penny though this project Life cycle stages and in this regard, the project deliverables are,

Good decision making skill of the leader of Paul and Penny to increase leisure facilities

To make the place Croydon most attractive destination through renovating the place

To ensure high quality leisure services by Paul and Penny

Contributing in the green environmental footprint at Croydon

High collaborative and enhancing communication among the staff for better leisure

Monitoring and control

For successful monitoring and controlling the project, it is mandatory to communicate properly with the reject manager and develops the project efficiently. The propjet is mainly renovate the new place Croydon for the organisation Paul and Penny on order to manage their operations and ensure high quality services in the luxury centres of Croydon. The entrepreneurs and the managers of Paul and Penny are efficient to enhance the internal communication and cooperation and it would be possible to progress in the project and control the activities. For communication, the leader tries to implement the Information and communication Technology (ICT) which further enhances communication with all the stakeholders engaged with the project including project managers, employees, interior decorator, service designers and supplier of the raw materials which are effective for the project managers to complete the project efficiently. There are CCTV cameras implemented in the place which is effective to monitor the progress and evaluate the performance of the employees in the place. The ICT and telephonic conversation as well as sending email and CCTV cameras are effective mode of monitoring and enhancing internal communication for evaluating the project activities so that it would be possible for the project manager at Paul and Penny to complete it with the effective time.

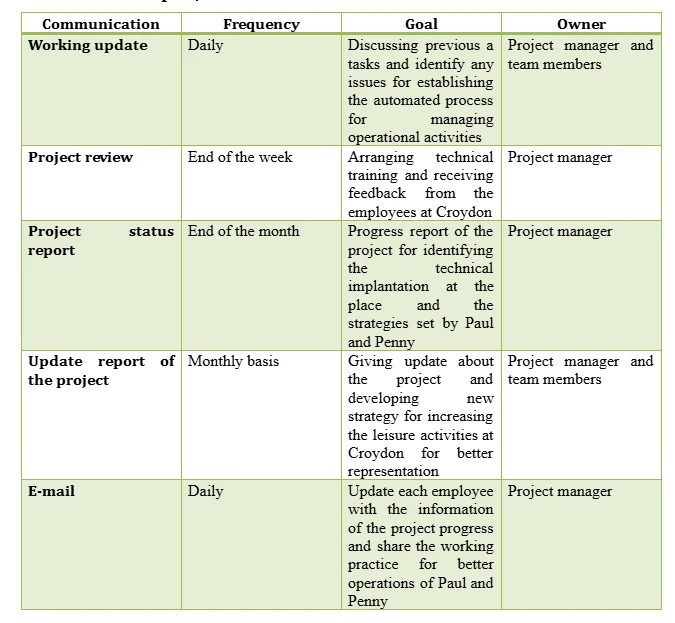

Communication plan

The above mentioned communication plan is effective for monitoring the progress and improve cooperation among the project managers, employees, technical team, plumbers and painters and interior decorators which are trying to participate in the project of Paul and Penny at Croydon in order to make the leisure destination attractive so that the firm can attract the trustworthy and long term customers towards the destination for enjoying their leisure time. In addition to this, for successful monitoring and controlling the project of Paul and Penny, key performance indicators of the project at Paul and Penny should be evaluated to monitoring and control the project. The key performance indicators are such as clarity, accountability, increased focus; reduce waste, making innovative decision, faster growth, increased visibility, higher returns and better performance. In this regard, the performance indicators of Paul and Penny are mainly the increased focus and the creative decisions making behaviour of the firm. The firm is able to make innovative decision to renovate the place Croydon and there is strong focus about the project for increasing leisure activities through latest facilities and technological advancement. For controlling the project, the technological innovation as well as the internal working activities are the major indicators or improving the performance and make the project successful. On the other hand, proper planning and budgetary plan are also effective where Paul and Penny is able to invest appropriate amount of capital in the project in order to manage the project and make the project successful.

Hence, suitable monitoring and control can be possible where the project manager and other staff members engaged with the project become efficient to handle the project collaboratively. Continuous monitoring, support and direction from the leaders are also effective for the organisation Paul and Penny to manage the project and make it successful.

Project closure

After monitoring and controlling the project managers try to hand over the project to the leader of Paul and Penny and in this regard the technical team, employees and to their staff members try to arrange meeting and review their working activities and engage with the organisational leader so that the leader can understand the project deliverables and evaluate the project successfully. In this regard, internal fittings and finishing, Installation of Security System, Installation of IT system as well as final preparations for opening are the major activities at the last pace of the project to complete it successfully. The project managers try to test the technology and review the whole place, check safety and security of the leisure services so that the leader of would be satisfied with the project and accept the project.

Analysing the rationale for use of WBS, Gantt chart, Critical Path, and leadership

Wok break down structure (WBS), Gantt chart and leadership practice are the major factors which have contribution on achieving the project objectives. The project management of Paul and Penny aims at develop WBS, Gantt chart and the suitable leadership practice in order to manage the project and make it successful in long run. The project objective of Paul and Penny is to expand their business by renovating the place Croydon for better leisure activities where Paul and Penny would be able to attract the long run customers for enjoying their leisure time with innovative activities and other additional facilities (Willar et al., 2018). The project managers try to develop WBS in order to maintain the efficient and accuracy of the project so that the working activities can be distributed among the employees and other stakeholders engaged with the project. The work break down structure is effective to have clear roles and responsibilities of the members engaged with the project at Paul and Penny and through the break down structure, the working activities can be completed and performed by each member efficiently, Hence, through WBS, it is possible for the project manager to handle all the staff and employees in the project at Croydon as well as give them clear instruction to work efficiently so that the project would be completed within the time. It further helps the estimate the costs and time for the project and ensure high quality project deliverable in near future, the WBS is also appropriate in this regard as per the PLC, to allocate the resources easily through proper planning. It further helps to organise the team and maintain good working collaboration and communication among the team members in or3edr to complete the project efficiently. On the other hand, the Gantt chart is also efficient for the PLC to develop proper timeline of the project. It further helps the project managers to set the programs as per the required time and estimate the total time for completing the project for Paul and Penny successfully. Effective time management and better reallocation of the resources can be possible through the Gantt chart as well as it also provides a scope to the project manager represent the project tasks in a synchronised way (Willar et al., 2018). Hence, it is fruitful to choose the WBS and the time line through Gant chart where the above mentioned WBS and time table are effective for the project manager at Paul and Penny for better project management and enhance their activities to complete the tasks efficiently within effective time. On the other hand, critical success path and the leadership style are also mandatory to be chosen during the project management activities at Croydon for fulfilling the objective of Paul and Penny. In this regard, the project managers develop critical success path to identify the tactics and technological innovation to develop the leisure services at Croydon which further help the firm Paul and Penny to be more innovative to represent the place of attracting the customers for long run. Leadership style is important factor for completing the project efficiently and in this regar4d the leader at Paul and Penny as well as the board members try to develop suitable working culture (Teixeira et al., 2019). Flexibility at the workplace as well as harmony and freedom to work are the practice where the employees feel free to work in the place Croydon. The leader of Paul and Penny is also efficient to support the employees and project manager with proper resources and organisational infrastructure to enhance their creativity and make the place attractive with all the latest leisure activities and additional facilities for the customers. On the other hand, the leadership style towards encouraging the employees and project managers with structured salary, performance related pay, supervisor quality and monitoring the progress through enhancing internal communication and cooperation are also effective for the project to achieve success.

Effectiveness of the application of the PLC

The application of PLC is good for the organisations to strategise the project and make effective planning for completing the project objectives successfully (Ashraf, Parveen and Khan, 2016). The PLC model is applied in Paul and Penny in order to strategise their project activities and maximise its objectives (Zare Ravasan and Mansouri, 2016). The major objective and scope for the project are developed through PLC model and additionally, the project initiation is done efficiently by identifying the steps of arranging the project and choosing the right place for Paul and Penny which is Croydon. The organisation is also efficient to reallocate the resources and arrange the required resources through the PLC model, where the budgetary plan, work break down structure as well as time table are effective for project planning. Hence, the PLC model is good and effective for Paul and Penny to arrange the resources and invest it in the project to renovate the pace Croydon for the leisure activities. PLC model also provides a scope to launch the project and develop organisational infrastructure for making the place attractive with effective painting, interior design, facilities and hospitality services available for the customers (Odia and Idowu, 2019).

Applying theories for large and small scale projects

The PLC model and the above mentioned leadership theories and practice, WBS and time table are effective for both the small and large sized project in order to manage the project activities successfully (Xingzhong et al., 2019). Proper reallocation of the resources, hiring new experienced staff members as well as developing communication plan and work break down structure are possible through the model where step by step activities provide a scope to the project manager to progress in the project and make it successful within estimated time (Alexander, Ackermann and Love, 2019). The budget planning and project estimation are also effective where the model is beneficial or the small and large sized projects to make the project successful and complete it efficiently by fulfilling the project objectives (Lin and Huang, 2020).

Conclusion

PLC is effective model for Paul and Penny to progress in the project and fulfil the aim of renovating Croydon for the ultimate leisure destination for the customers. as per the project planning, approximately £2 million budget are required as well as it is expected that the project needs 145 days to complete it successfully by implementing all the necessities, leisure activities and additional facilities for renovating the place efficiently for the ultimate tourist attractions. Hence, PLC provides a scope to the project manager at days to arrange the required resources and raise the capabilities of the organisation to arrange the team, manage the stakeholders engaged with the project and monitoring and control the executing of the activities to complete it successfully.

Reference List

Alexander, J., Ackermann, F. and Love, P.E., 2019. Taking a Holistic Exploration of the Project Life Cycle in Public–Private Partnerships. Project Management Journal, 50(6), pp.673-685.

Aoki, K. and Wilhelm, M., 2017. The role of ambidexterity in managing buyer–supplier relationships: The Toyota case. Organization Science, 28(6), pp.1080-1097.

Ashraf, K., Parveen, S. and Khan, A.R., 2016. ANALYSING IMPORTANCE OF PROJECT LIFE CYCLE MANAGEMENT IN CONSTRUCTION INDUSTRY. Integral Review: A Journal of Management, 9.

Chiarini, A., Baccarani, C. and Mascherpa, V., 2018. Lean production, Toyota production system and kaizen philosophy. The TQM Journal.

Coetzee, R., Van der Merwe, K. and Van Dyk, L., 2016. Lean implementation strategies: how are the Toyota Way principles addressed?. South African Journal of Industrial Engineering, 27(3), pp.79-91.

Gerard, P., Chiu, L. and Shilagani, C., 2020. Using Toyota Methodology To Improve The Operations of the Nuclear Medicine Department: Lessons Learned. Journal of Nuclear Medicine, 61(supplement 1), pp.1164-1164.

Gerard, P., Chiu, L. and Shilagani, C., 2020. Using Toyota Methodology To Improve The Operations of the Nuclear Medicine Department: Lessons Learned. Journal of Nuclear Medicine, 61(supplement 1), pp.1164-1164.

Ichinose, R., Sato, T., Masuda, A., Yamamoto, K., Yukihiko, O.N.O. and Oshima, A., Hitachi Ltd, 2018. Use-assisting tool for autonomous mobile device, operation management center, operation system, and autonomous mobile device. U.S. Patent 10,055,694.

Iwao, S., 2017. Revisiting the existing notion of continuous improvement (Kaizen): literature review and field research of Toyota from a perspective of innovation. Evolutionary and Institutional Economics Review, 14(1), pp.29-59.

Kawamoto, M., Mori, H. and Kitaoka, H., Toyota Motor Corp, 2017. On-demand vehicle operation management device, on-demand vehicle operation management method, and on-demand vehicle operation management system. U.S. Patent 9,836,974.

Odia, J.O. and Idowu, M.A., 2019. Management accounting practices in the tourism and hospitality industry. Development and transformation processes in the tourism industry under the conditions of globalization, pp.127-136.

Teixeira, R.M., Andreassi, T., Köseoglu, M.A. and Okumus, F., 2019. How do hospitality entrepreneurs use their social networks to access resources? Evidence from the lifecycle of small hospitality enterprises. International Journal of Hospitality Management, 79, pp.158-167.

Willar, D., VY, W.E., DG, P.D., Mait, R.E. and Rangan, J.J., 2018, October. Quality management of infrastructure project life-cycle. In 2018 International Conference on Applied Science and Technology (iCAST) (pp. 231-236). IEEE.

Xingzhong, L., Peng, S., Chao, H., Xianzhe, Z. and Center, S.M.O.D., 2019. Design and implementation of provincial meteorological equipment information management system based on project life cycle. Meteorological, Hydrological and Marine Instruments, (3), p.17.

Zare Ravasan, A. and Mansouri, T., 2016. A dynamic ERP critical failure factors modelling with FCM throughout project lifecycle phases. Production Planning & Control, 27(2), pp.65-82.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts