Optimizing ATI's Supply Chain

Introduction:

Abeer Trade Impex (ATI, 2018), Dhaka, Bangladesh, has an important role in the sector of garments supplying as the major areas of this company are garments accessories and raw materials management. In the recent years the company is facing some issues affecting its efficiency and profitability while this company is focusing on expanding its productivity in supply chain management in order to improve its operation in logistic exercise more effectively. This pilot study is going to identify these issues based on the data provided by three managers of this company. At the beginning of this study, the conception about the supply chain management and logistics will be clarified to identify the purposes of this project with a special emphasis on evaluating the role of the supply chain in order to advantageously utilise the resources and increase the profitability of the company. Finally, the study would be concluded by identifying the issues related to this concept assessing how these issues could be overcome to help the company to achieve its objectives effectively and move into the right direction. This researcher has been working under this company since 2015, and this research is going to illuminate the critical issues of this company related to supply chain management with possible solutions to these factors. In this research, different issues and problems of supply chain management faced by ATI will be identified, and solutions will be provided for them. Herein, the researcher will explore and evaluate a company’s supply chain thoroughly and identify any loopholes and problem areas. In this research, special attention will be given to the aspect of logistics management. It is essentially a sub-discipline of the supply chain (Benjaafar, Li and Daskin, 2013). While supply chain management deals with sources for obtaining the raw materials, logistics management can be associated with transporting the raw materials and their storage.

Dig deeper into Optimizing with our selection of articles.

The rationale of the study:

This topic has been selected for the current study because this researcher has been working in the company since 2015 and has come to the understanding that several supply chain issues hamper operations of the firm. It is now more important for the company that it identifies ways through which these issues and problems can be resolved (Carter and Liane Easton, 2011). If a proper solution for them is not determined, then there are chances that it would have a negative impact on the functioning of the company. Not being able to find a solution can not only impact ATI’s performance, but it can also seriously jeopardise its very existence. Thus, through this study, the researcher will focus on analysing and identifying the issues in the supply chain department as well as recommend ways through which they can be resolved. In order to carry out this research, the focus will be on analysing the whole supply chain and identify the issues. Once the issues have been identified, the researcher will evaluate each of the problems in a detailed manner (Klassen and Vereecke, 2012). Performing this step will help in getting a better understanding of the firm’s supply chain as well as the overall operations of the company. After evaluating the issues, the researcher will present some solutions through which the problems can be resolved easily and effectively. The current topic has been selected by the researcher mainly due to the reason that the scholar believes analysing this subject matter can help in improving the firm’s current position and find ways through which its performance as well as position in the industry can be maintained and improved (Gold, Seuring and Beske, 2010). Currently, the ATI needs to find a solution to its supply chain issues because if they persist, they can result in a significant diminishment of its performance as well as sustainability. In this research, logistics management will also be given thorough attention. By assessing this area, the scholar will determine the way company transports and stores the raw materials.

Rationale and Relevance

As identified above, this pilot study intends to analyse the issues faced by the supply chain department in institutional settings in Dhaka Bangladesh concerning the case of Abeer Trade Impex. Accordingly, Abeer Trade Impex is a leading garment supplier located in Dhaka, Bangladesh. The company deals with integrating raw materials and accessories needed for the production of the garment. The company, in recent times, has been striving to expand its base in supply chain management (SCM) to achieve efficiency in its logistics operation. However, the researcher who has worked in the company since 2015, has identified that the company is currently faced with several issues and challenges that have the potential to influence the operation of the firm. It is due to this reason that this topic has been selected for the study. Accordingly, this study attempts to identify solutions to the issues and challenges faced by the company concerning its SCM and logistics management. It is strongly believed that the failure to determine a suitable solution to the issues can have a significant negative impact on the operations of the company. Such failure not only has the possibility of jeopardizing the operation of the company but can also cause a threat to its survival. Therefore, it is important to conduct the study analysing the issues faced by the supply chain department of the company and determine the appropriate solution to the identified issues. Also, the current topic is considered for the study purpose, because the subject matter that this topic focuses has long term implications on the performance and the survival of the company. Hence, it requires an urgent solution to continue its operation competitively and profitably. The above section can be identified to offer sufficient justification for conducting the study. Apart from the above-identified factors, there are other factors as well, which makes the study relevant. In this regard, this study attempts to identify the key issues and challenges faced by Abeer Trade Impex, and at the same time, it provides some practical recommendations to the company that it can implement to address the issues being faced by the company effectively. Currently, the business environment in which the company operates is highly competitive and is characterized by a high degree of uncertainties. In such circumstances, any issue faced by the company has the potential to threaten the long-term survival of the business and may also have a dramatic impact on its overall competitiveness. Given the importance of the issue, it can be firmly argued that analysing and identifying the solution to the issue faced by the supply chain department of the company is highly relevant. Moreover, the topic that has been considered in this study is relevant for the participant’s professional doctoral study because this topic deals with the contemporary issues faced by many of the companies across the world. Accordingly, this study is anticipated to provide the participant with in-depth knowledge and understanding of the supply chain management issue specific to the garment industry in developing countries like Bangladesh. Additionally, the study not only provides academic insight and understanding about the research topic, but it is anticipated to greatly contribute to the professional development of the participant as the participant has worked for the company for almost four years.

The concept of Supply Chain Management

Over the last few decades, supply chain and supply chain management (SCM) has played an important role in improving the efficiency of business organizations and have been a major subject of discussion among the economist, and academicians (Janvier-James, 2012). As per Li (2014) supply chain is defined as the strategic coordination amid the supplier and the business organization to so supply as well as distribute certain products to meet the needs and demands of the customers. Nonetheless, it has been argued that the supply chain in the current competitive business environment plays a crucial role as it helps business organizations with faster production of goods in a cost-effective manner. The supply chain is viewed as one of the most important components of the business operation today, regardless of the type of market the business operates. Even though there has been a high degree of consensus about the definition and meaning of the supply chain but on the flip side, there lacks a clear common definition of the concept of SCM. It is because of a lack of universal definition of SCM that scholars such as Ley, Helms, Kimball & McMahon (2017) claimed SCM as an ‘elusive concept.’ One of the major reasons behind the lack of a common definition of SCM is provided by Min, Zacharia & Smith (2019). In this regard, the authors argued that over the years there had been continuous changes is taking place concerning the marketing trends as well as the use of new and advanced technologies are also increasing at a rapid pace. Notably, such market and technological changes are argued to be one of the main reasons behind the lack of a common definition of SCM (Min, Zacharia & Smith, 2019). Notwithstanding, several scholars in the past have proposed different definitions of SCM. In this regard, Agus (2015) stated that SCM involves the integration of vision, process as well as strategy to ensure optimal flow of high-quality raw materials from the suppliers to a business organization for providing customers with high-quality products at a competitive price.

On the other hand, Tan (2001) described SCM as purchasing, transportation, and logistics functions of an organization. These definitions of SCM lack unanimity. Nonetheless, this research study involves the use of SCM definition proposed by Mentzer et al. (2001). As per the authors SCM is defined as “systemic, strategic coordination of the traditional business functions and the tactics across these business functions within a particular company and across businesses within the supply chain, for the purposes of improving the long-term performance of the individual companies and the supply chain as a whole” (Mentzer, et al 2001, p. 18)

Concepts of Logistics Management

Logistic management is often being considered as complex and has been emphasized by numbers of scholars. It has been argued that difficulties associated with managing coordinating logistics activities within as well as among the firms are more likely to increase. It is, therefore, the demand for logistics management in recent times has grown significantly across different industries and organizations (Nilsson, 2006). Given the growing importance of logistics management, several scholars in the recent past have proposed a variety of definitions. According to Li (2014, p. 1), logistics is defined as “management of the flow of goods between the point of origin and the point of consumption to meet some requirements." On the other hand, logistics management is defined as a process that involves planning, implementing as well as controlling the flow of goods. Interestingly, the focus of logistics management is more on the transportation of goods than other components of the operations of the business (Akkerman, Farahani & Grunow, 2010). On the other hand, Klibi, Martel & Guitouni (2010) described logistic management as the process of placing the right thing in the right place and at the right time. Correspondingly, the main objective of logistics management is to ensure that the goods flow from manufacturer to end-users in an effective manner and help the business organizations to meet the needs of its target customers effectively and promptly (Gold & Seuring, 2011). In a similar context, Diabat & Govindan (2011) stated that the logistic management primarily deals with how the business organization responses to the customer demand and meet their demands and expectations. As per Tummala & Schoenherr (2011), it has been argued that in the current highly dynamic business environment, business organizations are required to adopt effective logistics management practices to create a loyal base of customers. On the other hand, the authors contended the failure of the business organization to embrace suitable logistics management practices could have severe consequences on the performance and operations of the business organization. It is anticipated to destabilize the entire operation as well as supply chain activities, which can have both monetary and non-monetary consequences on the business organization.

Supply Chain Management vs. Logistic Management

According to Li (2014), supply chain and logistics are generally comparative in the academy as well as industry because both these concepts deal with the product circulation, and both are considered to be an important element for attaining competitive advantage essential for the profitable survival of the business. Additionally, it has been argued that supply chain management is broader compared to logistic management. In this regard, supply chain management is ascertained to be composed of a variety of other management practices, including network sourcing, supply pipeline management, value chain management, and value stream management. On the other hand, Sodhi, Son & Tang (2012) logistic management is an important component of supply chain management. In a similar context, Mollenkopf et al. (2010) acknowledged that logistic management is the final stage in the supply chain management which ensures that the finished goods are delivered efficiently to the ultimate consumers. As per Croom, Romano & Giannakis (2000), the concept of logistics has no relationship with the organization and is claimed to be opposite the supply chain. In this regard, the authors argued that the SCM usually involves multiple organizations such as supplier, manufacturer, and distributor, among others, while the logistic management is argued to activities such as logistics facility, transportation, and inventory planning. Accordingly, unlike logistics management, an important issue associated with the supply chain management is that the organization may not try to achieve a reduction in the cost to the product more affordable at the expense of supply chain partners, but it usually seeks to achieve cost reduction by making the whole supply chain more efficient and competitive. Hence, the focus of SCM is not on singly supplier or company; rather, it involves focussing on all those partners and companies associated with the supply chain of a company (Gleissner & Femerling, 2014).

Importance of Supply Chain Management (SCM)

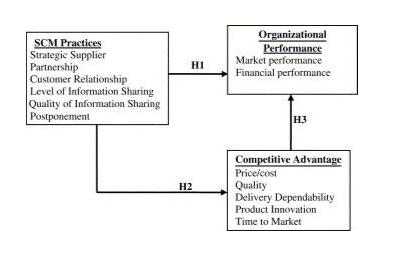

Over the last few decades, a bulk of research studies has been conducted in the field of SCM. The majority of the studies have stressed the importance of SCM and its impact on the performance of the firm (Kim, 2006; Ou et al. 2010). According to Wong, Boon-Itt, and Wong (2011), it has been argued that to succeed in the current highly competitive business environment, the business organizations are required to fulfil the needs and demands of the customers efficiently. In this regard, the author stressed that the implementation of effective SCM allows the business organization to provide high-quality products to the customers and fulfil their needs and deliver the highest customer satisfaction. In a similar context, Ou et al. (2010) argued that SCM has a direct impact on the performance of the firm. It has been claimed that the successful implementation of SCM has a positive impact on the operational performance of a firm. Additionally, the authors found that the SCM also has an indirect impact on customer satisfaction and financial performance. Moreover, the significance of the SCM for the business organization can also be identified from the fact that the businesses today are constantly striving to achieve greater competitive advantage over the rivals. These firms have adopted a variety of strategies and tactics, such as cost reduction, to achieve greater competitive advantage. In this regard, Van Wassenhove & Martinez (2012) argued the effective implementation of SCM and its practice allows the business organization to reduce its operational costs and further strengthen the competitive edge over its rivals. A similar idea has also been shared by Tan et al. (1999) in their study in which it has been claimed that one of the major challenges that have adversely influence the performance and competitiveness of a firm is due to the inability of the firm to integrate suppliers, manufacturers and distributors effectively. Similar view has also been postulated by Tan, Layman & Winser (2002) in their study in which they claimed that in the 1st century the importance of SCM has grown significantly and reported that the SCM has emerged as an important strategic tool for the business organizations that are striving to improve quality, customer services as well as competitive success. The findings from the study further supported that ineffective SCM practices have the potential to adversely influence the performance of the business organization while effective SCM practices can help the businesses to attain success and growth while sustaining competitive advantage. Thus, the evidence from the previous literature suggests that SCM is highly important for businesses that intend to achieve greater competitiveness and success.

Importance of Logistics Management (LM)

According to Sum, Teo & Ng (2001), it has been argued that in the current business environment, which is characterized by a high degree of uncertainties and competition, many business organizations are going global to acquire market share as well as to take advantage of production and sourcing efficiencies. Notably, one of the most important determinants is argued to be logistic management, which plays a crucial role in ensuring smooth flow of materials, products as well as information across the supply chain of business organizations. As per Rahman & Subramanian (2012), it has been argued that one of the major challenges being faced by business organizations today is to deliver products to ultimate customers timely and reduced cost. Corresponding, logistic management is stated to facilitate the business organizations to store the goods securely in the warehouse and distribute them efficiently to fulfill the customer’s needs. It has further ascertained that the business organizations today are involved in implementing different types of strategies to reduce costs and deliver products to the ultimate customers at a low price (Fassoula, 2007). In this regard, Hajmohammad, Klassen & Gavronski (2003) effective logistics management practice in a firm has the potential to reduce the cost while improving the overall profitability of the firm. Notably, logistics management practices that are efficient and systematic allow the firm to eliminate errors and mistakes associated with material handling which in turn reduces the waste of materials during transportation and distribution. As a result of which, the firm can reduce its production and distribution costs and help improve its profitability. As per Thun & Hoenig (2011), it has been argued that for the firms, it is challenging to set up manufacturing plants across all countries and regions of its operation. Therefore, logistic management allows the firm to safely transport and deliver the goods to the end-users and help in the expansion and growth of the firm. Hence similar to SCM, the existing literature provide sufficient evidence regarding the importance of logistics management for the firms.

Issues in Supply Chain Management

The business environment is constantly changing, making the SCM more complex and challenging. Today, the business organizations are faced with numbers of SCM related issues and challenges, which is critical to address to achieve efficient SCM and take advantage of the SCM practices for the success and growth of the organization (Storey et al. 2006). One of the major SCM issues faced by firms today is related to the issue of globalization. Notably, the phenomenon of globalization has allowed the firm to expand the business rapidly across different geographical locations. However, it has created a significant challenge for the firm to build a strong network of supply chains and execute effective SCM practices. It has increased the risk of losing control over the operation, visibility, and mismanagement over inventory (García, Florez & Torralba, 2013). In a similar context, the fluctuating demand, the rapid rise in the cost of materials followed by depreciating currencies, has also made it difficult for the firms to achieve effective SCM and perform its supply chain activities smoothly (Gao, Demirag & Chen, 2012). Similar concerns have also been raised by Eltayeb, Zailani & Ramayah (2011). In this context, the authors in the wake of constantly rising cost of raw material cost, production cost, and transportation cost, it has become a major challenge for the business organizations to control cost and deliver quality products to its target customers at the affordable price. Another major issue is related to the developing of the sustainable supply chain. Notably, several scholars in the past have stressed the importance of a sustainable supply chain, but the high cost of maintaining a sustainable supply chain has made it difficult to realize a sustainable supply chain (Seuring & Müller 2008).

Future directions in supply chain management

As identified above, there are several issues associated with the SCM. Correspondingly, business organizations need to tackle these issues effectively and engage in the continuous improvement of SCM and logistics management (Chapman & Corso, 2005). In this regard, the different scholars have suggested different strategies and tactics for realizing improvement in SCM practices. According to Olhager & Selldin (2004), it has been argued that SCM communication is changing rapidly with the advancement in the new technologies. Correspondingly, it has been suggested that the firms need to prepare it and develop strategies for incorporating new technologies and ways for improving SCM communication. At the same time, Lee (2002) argued that business organizations are faced with an increased level of uncertainties, which has the potential to influence the logistics and supply chain management practices negatively. In this regard, it has been stressed that the business organization needs to align its SCM strategies with the uncertainties prevailing in the market of its operations to maintain effective control over supply chain risks. Also, Green et al. (2012) suggest that the firms in the current contest should integrate environmental issues into their SCM practices. Notably, such integration is claimed to take the firm closer towards attaining sustainable SCM practices.

Outline of Research Methodology, Methods and Sample

Research Methodology

To understand the reality of the research subject, the interpretive research philosophy is used. According to this philosophy, the reality of a research subject can only be understood by a subjective perspective. Therefore, the personal opinion of the researcher plays an important part in understanding the research subject. Unlike positivist philosophy, in this philosophy, the research subject is studied under the natural setting. Interpretive philosophy considers that there can be different explanations of realism and such explanations are considered as a part of scientific understanding of the topic (Kumar, 2014). In the meanwhile, the subject supply chain issues in ATI is believed to be subjective. Furthermore, the research has been conducted in its natural setting as it is considered that if the respondents are separated from the natural setting, they will give different responses, and therefore, the truth about the issues faced by the company cannot be revealed. The research considered human interest. It is believed that the realism about supply chain issues in ATI is socially constructed, and therefore by taking the opinions of different respondents, the truth can be obtained. It has appreciated different explanations of people and is not focused on using only one method for collecting opinions. In this research, a mixed approach is used for conducting the study. This approach is based on including both qualitative and quantitative data to understand the research subject. By integrating both methods, a mixed approach influence the entire research procedure. In this approach, methods which are best suitable for comprehending the research subject is used. Using a mixed approach has made the study much comprehensive and also complex (Creswell & Plano-Clark, 2007). The research not only uses personal opinion but also the opinions of the respondents. It is based on dynamic interaction with people who are involved in the supply chain practices of ATI. Mixed methods work on explanatory, exploratory, and case study, among other formats. However, in this research, the exploratory format is used. This format is used for discovering thoughts and insights regarding a research subject. In this context, the key emphasis of the research is also to obtain ideas and insights about supply chain issues in ATI. The pilot study is conducted to give an understanding of the situation of the supply chain department in the organization, rather than coming up with a decision to solve the issues (Creswell, 2013). By this format, it is hoped to produce a hypothesis about what is going on in ATI about supply chain difficulties.

In this research, the inductive reasoning method is used. The research is based on logical thinking. In this research, at first, observation is made by conducting a literature review on the subject of supply chain issues. Afterward, a pattern about the research subject is understood through collecting data from different primary sources, and after analyzing the data, a tentative hypothesis has been made on the subject, and finally, generalization has been made based on specific details obtained (Babbie, 2010). In the research, the conclusion about the subject is drawn from the information acquired at different phases.

Data Capture, Analysis, Findings, and Conclusion

Data Capture

Findings from the Questionnaire

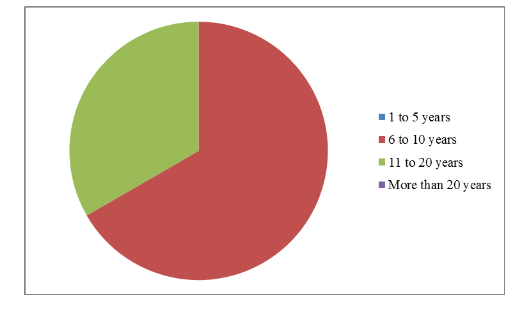

To analyse the issues currently faced by ATI, a questionnaire survey has been conducted with three managers of the company. They are provided with a sample of questions regarding organizational specifies supply chain issues. Their responses have provided a valuable understanding of the problem faced by ATI. Among the 3 respondents, 2 are male, and 1 is female. Two of them have experience of about 6 to 10 years, and only 1 manager has experience of about 11 to 20 years. This indicates that the managers have sufficient knowledge regarding the organizational supply chain operations and the underlying issues it is facing.

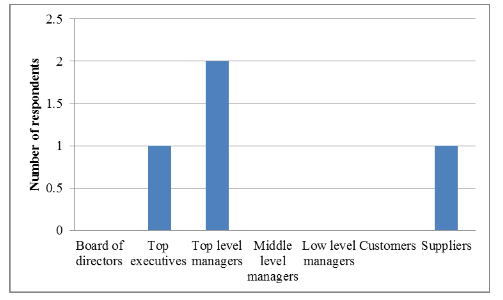

Initially, the managers are asked who in the company is involved in developing supply chain practices. In this context, most of the respondents (2) have mentioned top-level managers, and 1 respondent has mentioned middle-level manager. One respondent also mentioned suppliers involved in supply chain practices.

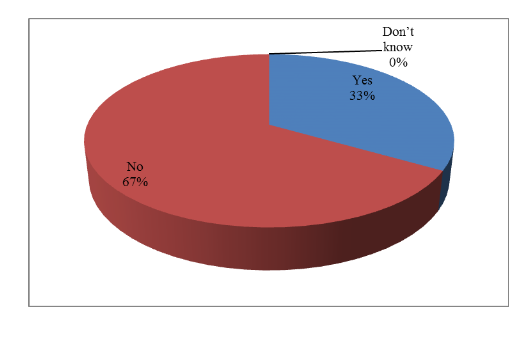

The respondents are asked if the company evaluates supply chain management practices. 2 respondents have stated no to this question. This leaves the supply chain issues unnoticed by the company and hence impact on the performance.

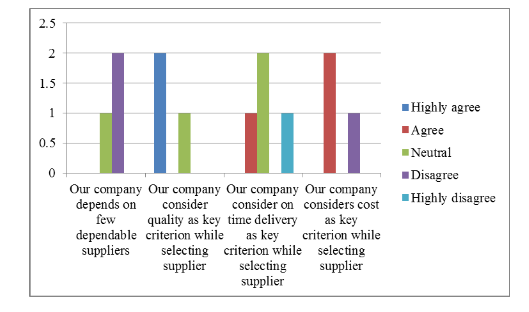

To understand the issues of supply chain management, questions have been asked in various sections. The first section to analyse is to analyze existing supply chain management practices of the company. Understanding such practices will help to understand the current drawbacks regarding supply chain management activities. The respondents are asked to mark their level of agreeableness on certain statements regarding supply chain practices. The first aspect of supply chain practice is several suppliers, where most of the respondents disagreed with the fact that the company depends on a few dependable suppliers. This certainly is a positive aspect for ATI as more suppliers will result in less reliance and also better-quality products at the right price. The second important aspect of supply chain practice is quality. In this aspect, most of the respondents have highly agreed with the fact that the company considers quality as a key criterion while selecting a supplier. This indicates that ATI is concerned about maintaining a certain quality standard for its garment products to satisfy the customers. The third important aspect for analysis of supply chain practice is on-time delivery. In this aspect, most of the respondents were neutral. This specifies that timely delivery is less concerned or focused less in comparison with other aspects of supplier selection. This certainly can result in a delay in product delivery for the company. The fourth important aspect is cost, where most of the respondents have agreed that it is a key criterion for selecting a supplier. The reason can be high costs can increase the prices of the garments and therefore will not be acceptable by the clients. Thus, maintaining cost is a priority for ATI.

Maintaining a long-term relationship is another important aspect of supply chain practice. In this aspect, most of the respondents have agreed with the fact that the company strives to develop long term relationships with the suppliers. Without a good relationship, ATI will be unable to procure the required raw materials for fulfilling the orders of the customers. Therefore, maintaining a profitable business relationship is of great importance for ATI. However, most of the respondents have disagreed with the fact that the company helps suppliers to improve their performance. This is another important drawback for the supply chain practice of the company. Without mutual support, supply chain performance is unlikely to improve. Most of the respondents also disagreed with the fact that the company regularly solve problems jointly with the suppliers. This specifies that the cooperation between the company and the supplier is missing within the supply chain practice of ATI.

The second important section analysed through the questionnaire is supply chain integration within the company. Better supply chain integration can lead to better supply chain performance. To better integrate, a company require to constantly notify about any important event of business importance to the supply chain associates. However, most of the respondents have found to neutral on the aspect that the company keeps the supply chain members to stay up to date regarding any events or changes in the business. Concerning the timely exchange of information, most of the respondents have agreed with the fact that the company exchanges information in a timely way. This helps to ensure better communication with the supply chain associates. The respondents disagree with the fact that they push the suppliers for shorter lead times.

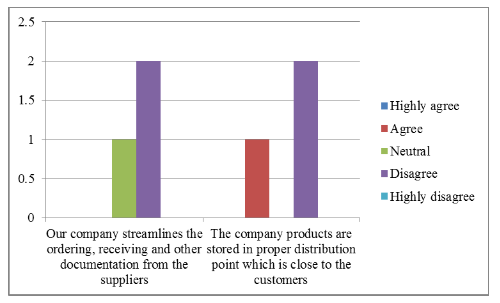

Supply chain performance is also dependent on the streamlining of key business operations like ordering and receiving of documents etc. Most of the respondents have disagreed with the fact that the company streamlines the ordering, receiving, and other documentation procedures from the suppliers. This can lead to delay in product delivery and also impact on logistics performance due to slow documentation process. Furthermore, most of the respondents also disagreed with the fact that the company products are stored in a proper distribution point, which is close to the customers. This certainly results in more lead time to transport the products to the customers. Inappropriate distribution points also lead to high expenses, and it is an important issue faced by the logistics division of the company.

The next section for the supply chain analysis of ATI is the supply chain performance of the company. It helps to reveal the issues that hamper the performance of the company. The effectiveness of supply chain performance is subject to the capability to respond with the variation in demand and seasonality. Demand can vary due to many reasons like changes in economic or political conditions of the nation. Furthermore, the garment sales are also seasonal, which requires matching the supply with the demand. In this aspect, most of the respondents have marked the performance of the company good, i.e., it can deal with demand variation and seasonality. The entrance of new competitors in the market also has a strong impact on business. In such a context, the supply chain performance must be adjusted to deal with the competitors and to provide products effectively to the customers. However, concerning the ability to react with the new competitors, most of the respondents stated it is moderate. Therefore, there is space for improvement on this ground through better supply chain management. In any industrial segment, including garment, on-time delivery is an important aspect of obtaining customer satisfaction. Without it, customers can switch to other companies. This on-time delivery is mostly depended on supply chain performance and particularly the logistics performance. However, most of the respondents have stated that the on-time delivery of the product to the customers of the company is bad. This can be due to issues in the supply chain or logistics division of the company, which requires to be solved. On the time delivery of products is subject to on-time acquisition of raw material to a certain extent. Without on time acquisition, the production and other operational procedures will be delayed, leading to a delay in product delivery to the customers. This is also an important aspect of performance for supply chain and specifically logistics. Most of the respondents also market that the on-time acquisition of raw materials of the company is bad.

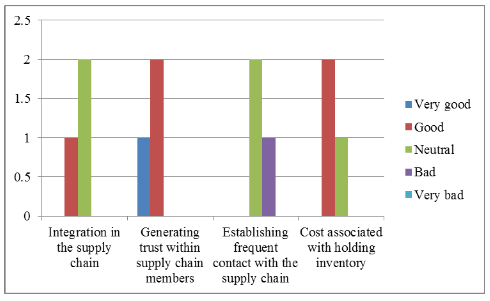

The next aspect analysed is the integration of the supply chain. It is important as better integration leads to better information exchange, knowledge sharing and better coordination. As a result, it helps to enhance the performance of the supply chain through on-time product management and delivery. Supply chain integration is also important for better logistics support. However, most of the respondents have stated that the supply chain integration of ATI is moderate. Therefore, the company will require enhancing integration for better management of supply chain and logistics. Trust is also a vital factor in supply chain performance. Without mutual trust, there will be incongruence between the company and the supply chain partners, which will impact on the performance. In this aspect, most of the respondents have verified that generating trust within the supply chain members is good. To make supply chain partners work effectively and to make them react with the changing demand or changes in the business environment, there is a need to establish frequent contact. The supply chain members must be notified frequently in case of any future changes in business activities. Most of the respondents stated that the performance of ATI concerning establishing frequent contact with the supply chain is moderate. Therefore, ATI needs to contact frequently regarding any events which can have an impact on business relationships and activities. Better supply chain performance is characterized by maintaining a minimum level of inventory, as holding much inventory can lead to additional expenses for holding. Furthermore, concerning garment products, there is a frequent change in style, trend, and fashion, which requires changes in products. This necessitates organizations to maintain sufficient inventory, essential for fulfilling the current demand of customers. Most of the respondents have mentioned that for ATI, the performance about holding inventory is good. This specifies that ATI is effective in maintaining appropriate stock levels by avoiding surplus stock and hence can save expenses of a business.

Concerning production lead time, most of the respondents have stated that the performance of the company is good. This low production lead time helps the company to develop the products within time and make the product ready for delivery. Apart from that, low production lead time also result in high productivity and increased capability for fulfilling the demand of customers. In the supply chain, proper resource allocation plays a vital part. Supply chain effectiveness is subject to better allocation of resources like financial resources and human resources so that the organization can economically as well as optimally satisfy the market demand. However, in this aspect, most of the respondents have stated that the resource allocation of ATI is bad. Thus, the company requires managing the resources effectively through a better resource allocation plan and better scheduling so that one function does not overlap with others and each function has sufficient resources to complete on time. Concerning logistics, the resource typically refers to available vehicle and distribution networks, which must be improved for ATI. Finally, the last aspect amassed concerning supply chain performance is shipping errors. A high level of shipping errors can result in a high level of customer dissatisfaction. In this aspect, most of the respondents have mentioned that performance for shipping errors is good for the company, signifying that there is a low level of shipping errors that occurs in the company.

Supply chain management performance is dependent on a variety of functions. These functions, if not conducted effectively, can create issues in the supply chain. To understand the importance of different functions for the supply chain performance of ATI, these functions are analysed for their impact. The first function is inventory management, on which most of the respondents stated that this function has a moderate impact on the supply chain management performance of the company. Since the garment products are not perishable, they can be inventoried for a long time. The second function is transportation, on which most of the respondents have stated that this function has an impact on the supply chain to a great extent. This indicates that ATI transportation and logistics are important. The company requires obtaining products and delivering the same through within proper time because the demand for garment products is seasonal and changes frequently; and without good transportation, it will result in a delay in procurement as well as delivery of products, resulting in loss of opportunity and also dissatisfaction for customers. Business process improvement is another important aspect of supply chain performance. Business process improvement leads to the development of the entire supply chain network through better communication, better management of resources, and better stock control among others. For most of the respondents, this aspect has a high impact on the supply chain performance of ATI.

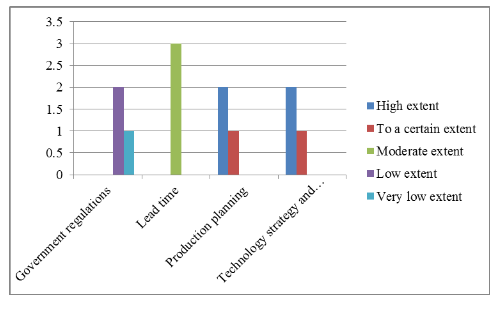

Government regulations can also impact the supply chain performance in terms of transportation, logistics, and documentation while shipping, among others. However, most of the respondents mentioned government regulations have a low impact on the supply chain management of the company. Concerning lead time, most of the respondents also mentioned this aspect impact on supply chain management moderately for ATI. Production planning is another important aspect of supply chain management. The amount of ordering and selling is subject to the level of production planning by the company. Therefore, most of the respondents mentioned this aspect could impact on the supply chain performance to a great extent. Hence, ATI needs to plan production activities effectively. Finally, technology has a great impact on the supply chain management performance of a company. Technology implementation can result in better supply chain integration and better communication between the company and supply chain associates. Furthermore, technology also helps to manage the resources effectively through better planning. Most of the respondents also mentioned technology strategy and implementation impact on supply chain management to a great extent.

Analysis and Findings

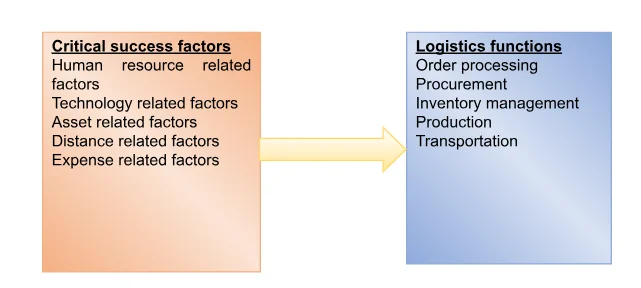

In general, the pilot study revealed that ATI faces many difficulties concerning its supply chain and, specifically, logistics. There is a problem with the integration of the supply chain in Bangladesh because the segment is fragmented in nature. There are many players of the supply chain in the garment industry in Bangladesh at different tiers, and they use different systems or processes. This complicates the operational practices of these players. ATI presently faces logistics problems and therefore, at times it unable to deliver the products on time. One of the key factors impacting the supply chain logistics performance of ATI is ineffective resource allocation. Apart from that, planning, inventory management, business process improvement, technology implementation, human resource management, and supply chain integration also impact on the supply chain performance to a large extent. From the findings, it has been learned that in ATI lack of proper communication and information exchange that at times, result in procedural issues. There is also a lack of talented employees in the company. The company faces problems with information processing since most of the processing activity is done manually, which quite time-consuming and also leaves an opening for human error or omission. There is no real-time solution for inventory management, which makes tracking the inventory of the company difficult. These hurt procurements, production and hence the supply chain activity. The cost of production and transportation is another important issue revealed in the interview. The cost of production is dependent on the cost of raw materials and the cost of human resources. Furthermore, the geographical distance also impacts on the cost of logistics. ATI also has been found not to streamline activities like order processing, procurement, and inventory tracking. This results in poor visibility throughout the supply chain. From the interview, various factors have been identified which impact on the logistics activity of ATI, which are demonstrated in the following figure.

The human resource factor is key aspects of production and distribution because ATI is a labour-intensive company. The abilities of the employees, their competency in production and other activities and their experience and talent regarding supply chain influence on the logistics performance of the company. Furthermore, technology is also important for ATI to better compete with competitors in the market of Bangladesh. Proper inventory management is crucial for ATI to reduce the expenses of inventory carrying and also ensure the proper availability of raw materials. Distance is also crucial for the supply chain performance of ATI. It impacts on the expenses of products and also the lead time for production and distribution. The production activity is also dependent on inventory management. Improper inventory hampers production and, therefore the entire supply chain logistics of ATI.

Conclusion

The list of issues for supply chain inefficiency ion ATI is quite comprehensive. Yet the conclusion drawn from the findings and analysis is that the human resources, technology, and procedures of the company need to be developed for supply chain effectiveness. Finding skilled employees and giving them training, automation in MRP and procurement requirements, real-time updates of inventory data, and tracking systems in logistics are important for enhancing the supply chain in ATI. There is also no evaluation in supply chain performance in ATI. Therefore, it is recommended that the supply chain performance should be measured by developing proper metrics, which will help to identify the drawbacks in the system and operational procedures and will help to take measures. Obtaining feedback from the customers and employees can help to achieve that. Implementation of IT for better communication and integration is also important for the supply chain efficiency of ATI. In conclusion, it can be stated that ATI requires applying a proper supply chain management strategy to become competitive in the marketplace.

Reflection

Introduction

The purpose of this article is to demonstrate the reflections on the pilot study, which possess a phase of the Ph.D. research of the author. These reflective reports should give light on various problems faced as one of the ways to eradicate them in the major data collection process. Reflection is the method that helps the researchers to have a look over their past experiences and attain knowledge from them. Procee (2006) has stated that although reflection is one of the difficult parts but could be meaningful if it applies mainly three principles, which includes the purpose of the reflection, the process used in reflection, and give focus on the experiences needed to reflect. This study will make the application of Kolb’s experimental learning cycle as one of the reflection models whereas the reflection process will be based on four stages of Kolb. The first stage possesses concrete experiencing, which will explain the experiment, whereas the second stage includes reflective observation, which possesses experience’s reflection. The third stage possesses abstract conceptualizing which is studies from reported experienced and lastly active experimentation which plans for collected data.

Context of the study

This project was aimed at analyses and solved the issues of the supply chain department in an institutional setting (Abeer Trade Impex) in Dhaka, Bangladesh. Both questionnaire surveys collected the data and interviews to attain productive results. The motive was to analyses the problem faced by ATI in supply chain departments. Since communication is the main element in an organization, the lack of communication and communication techniques have led to various issues in an organization. Because of the importance of communication in an organization, there is the organizing of the training programs which could help the employees to teach English and motivate the company boards to employ informational technology in an organization (Agbatogun, 2014).

The Reflection

Based on the Proceee’s(2006) principles for what needs to be applied in the reflective report, the main aim of this reflection is to acknowledge the issues faced nu the researcher in the collection of the data experimentally mainly which are related to the study so as to solve them prior to the main collection of data. The reflection’s process is being informed by Kolb’s experiential learning cycle, and the major focus is on a pilot study that hopes to assist other different researchers.

Kolb’s experiential learning model

Kolb’s learning theory is a set of four distinct learning styles that are linked with a four-stage learning cycle. This model helps in understanding the individual people's variant learning styles and explains the experimental learning which is applied in it. The Kolb models possess a four-stage cycle, which includes concrete experience, reflective observation, abstract conceptualization and active experimentation (Adams, Kayes and Kolb, 2005).

Concrete experience

The pilot study was mainly taken place to evaluate if research instruments like the interview guide and written tests are worthy or not. It is one of the major opportunities to review the validity and authenticity of the research instruments, measure the supply chain performance, review the communication skills and test the usage of IT as suggestions given in the interviews. This part of the research started by attaining approval from the director of the company to carry out research and have a meeting with the manager of supply chain departments. The proper investigations of the company were performed, and the communication skills of the employees were also tested through various tasks and games. The activities of employees were observed in detail wherein the external observer was found to look after the various tasks taken place with the employees. Moreover, the proper analysis was taken place in each corner of the company to analyses the usage of IT in their workplace. However, the shortage of time had made it difficult to review the overall details.

Reflective observations

The reflection took place after the pilot study to analyses the advantage and disadvantages of the pilot test procedure as well as instruments. It is highly required to reflect the problem faced to abstract and manage the data collection. This study which aims to test the issues of supply chain department in ATI, the researcher might face obstacles in doing so. In this study, the researcher analysed issues linked to the supply chain department and to those setting where the data was being collected. One of the major issues faced by managers was communication problems. It is stated that ATI managers mostly face the issues of insufficient communication wherein many of the times, information is not delivered to the other end properly, and most of the time, it leads to delay in operation. These gaps in communication lead to an ineffective work process. The lack of communication has also blocked the fluidity of the work process, and the parties are not informed about important events that had influenced the business organization. The second problem type prevailing in carrying the pilot study was linked with the time assigned for it. Because it takes more time to teach communication skills, there was a requirement of more time to train the employees to have effective communication and ways to make sound communication environment. In general sense, the intervention task requires more time than its planning as unknown problems could arise, which results in time scarcity. In addition to that, many respondents or participants might underestimate the value and have not taken the test seriously. Lastly, there were also other various issues and obstacles linked with resources such as technical issues like lack of information technology, internet connections, which have made this test more complicated.

Abstract conceptualizing phase

Taking the reflection as well as to avoid indulged in any sorts of issues at the time of the main data collection, two points need to be reviewed. It was included in the pilot study that there is a lack of information technology which delays the communication between the employees and clients. Thus, the company must appoint information technology and speed up communication so that there could be a building of a relationship between clients and employees. Moreover, there must be better preparation and planning for the data collection of the main files. This can be possible by having a contact with the IT professionals to make availability of required technical resources. Such preparation could help in increasing the profile of the researchers along with the participants and avoid any sorts of difficulties.

Active experimentation phase

Taking the abstract conceptualization into consideration and summing the procedures allocated to refuse such issues in the main collection of data, it can be stated that there needs to be an improvement that needs to be made before the collection of data. It is thus planned to enhance the information technology and apply the training to focus totally on the development of the communication skills of the workers. In addition to that, it is also planned to be in the company one week before the collection of the data. The company owner will also be asked regarding the reason for the non-availability of the information technology and will try to solve all the issues regarding the technical matters.

Conclusion

There are various issues linked with this pilot study, and steps will be taken before entering the further phases and will be analysed. The main aim of the pilot study is to test the instruments of research and analyse the kinds of issues that would be faced at the time of collection of the data. There was a plan to set the data and manage it effectively.

References

- Agbatogun, A. O., 2014. Developing learners' second language communicative competence through active learning: clickers or communicative approach? Educational Technology and Society, 17(2), 257-269.

- Agus, A. (2015). Supply Chain Management: The Influence of SCM on Production Performance and Product Quality. Journal of Economics, Business and Management, 3(11), 1046-1053.

- Akkerman, R., Farahani, P. & Grunow, M. (2010). Quality, safety and sustainability in food distribution: a review of quantitative operations management approaches and challenges. O R Spectrum, 32(4), 863-904.

- Chapman, R. L. & Corso, M. (2005). Introductory paper from continuous improvement to collaborative innovation: the next challenge in supply chain management. Production Planning & Control, 16(4), 339-344.

- Creswell, J. W., & Plano-Clark, V. L. (2007). Designing and conducting mixed methods research. Thousand Oaks, CA: Sage Publications.

- Croom, S., Romano, P. & Giannakis, M. (2000). Supply chain management: an analytical framework for critical literature review. European Journal of Purchasing & Supply Management 6, 67-83.

- Eltayeb, T.K., Zailani, S. & Ramayah, T. (2011). Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resources, conservation and recycling, 55(5), 495-506.

- García, J. Florez, E. J. & Torralba, A. (2013). Combining linear programming and automated planning to solve intermodal transportation problems. European Journal of Operational Research, 227(1), 216–226.

- Gold, S. & Seuring, S. (2011). Supply chain and logistics issues of bio-energy production. Journal of Cleaner Production, 19(1), 32-42.

- Green, K. W., Zelbst, P. J., Meacham, J., & Bhadauria, V. S. (2012). Green supply chain management practices: impact on performance. Supply Chain Management: An International Journal, 17(3), 290 – 305.

- Hajmohammad, S., Klassen, R.D. & Gavronski, I. (2013). Reprint of lean management and supply management: their role in green practices and performance. Journal of Cleaner Production, 56, 86-93.

- Kim, S. W. (2006). Effects of supply chain management practices, integration and competition capability on performance. Supply Chain Management, 11(3), 241-248.

- Lee, H. L. (2002). Aligning supply chain strategies with product uncertainties. California Management Review, 44(3), 105-119.

- LeMay, S., Helms, M., Kimball, B. & McMahon, D. (2017). Supply chain management: the elusive concept and definition. International Journal of Logistics Management, 28 (4), 1425-1453.

- Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S & Rao, S. S. (2006). The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), 107-124.

- Min, S., Zacharia, Z. G. & Smith, C. D. (2019). Defining Supply Chain Management: In the Past, Present, and Future. Journal of Business Logistics, 40(1), 44-55.

- Nilsson, F. (2006). Logistics management in practice – towards theories of complex logistics. The International Journal of Logistics Management, 17(1), 38-54.

- Ou, C., Liu, F., Hung, Y. & Yen, D. (2010). A structural model of supply chain management on firm performance. International Journal of Operations & Production Management, 30(5), 526-545.

- Seuring, S. & Muller, M. (2008). Core issues in sustainable supply chain management – a delphi study. Business Strategy and the Environment, 17, 455-466.

- Storey, J, Emberson, C., Godsell, J. & Harrison, A. (2006). Supply chain management: theory, practice and future challenges. International Journal of Operations & Production Management, 26(7), 754-774.

- Tan, K. C. (2001). A framework of supply chain management literature. European Journal of Purchasing & Supply Management, 7, 39-48.

- Tan, K., Kannan, V. R., Handfield, R. B. & Ghosh, S. (1999). Supply chain management: an empirical study of its impact on performance. International Journal of Operations & Production Management, 19(10), 1034-1052.

- Thun, J.H. & Hoenig, D. (2011). An empirical analysis of supply chain risk management in the German automotive industry. International journal of production economics, 131(1), 242-249.

- Van Wassenhove, L.N. & Martinez, A.J.P. (2012). Using OR to adapt supply chain management best practices to humanitarian logistics. International Transactions in Operational Research, 19(1-2), 307-322.

- Wong, C.Y., Boon-Itt, S. & Wong, C.W. (2011). The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. Journal of Operations management, 29(6), 604-615.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts