The Future of Logistics: Anticipatory Approaches

Anticipatory Logistics Practices in Industries

AL practices are being implemented in different industries, which have an increasing need to reduce lead times for order deliveries. In the present day, there exist companies which meet the demands of customers by offering one-hour and same-day delivery services. While fulfilling the speedy needs of customers, the same businesses try to balance their costs of making such deliveries. Some demands come spontaneously from customers, therefore, as a way of making on-demand deliveries, and saving costs of having to use their own distribution hubs, companies use services like Uber and Postmate (Brown, 2019). Meeting same-day demands requires an extraordinary and beyond conventional approach of supply chain optimization. Thus, similar to how a retailer can offer promotional discounts to sell overstocked inventory in real time, the businesses leverage customers, through incentives such as reduced charges, free miscellaneous services and other promotional offers, to select the means of delivery which are return the highest profit. Companies, thanks to technology advancements in significant industries, can meet speedy demands effectively. Precisely, increased data storage and information processing technologies have paved way for predictive analytics to be used in forecasting customer demand patterns in the future of a given industry. By possible means, where accuracy would be at 100%, companies can even make deliveries ahead of an order actually being placed by a customer using predictive analytics in the version of anticipatory logistics (Pathekkara, 2016). Although, due to AL being a relatively new concept, it is yet to be perfectly implemented in several organizations, or, rather, its elements are not fully exploited in different industries. The following industries have illustrated the implementation of AL practices.

E-Commerce Sector

Anticipatory Logistics in Economic Sector

The e-commerce economy is characterized by the extensive application and popularization of internet technology, which takes advantage of the changes in the social economy using the growing digital information and electronic communication. The immediate developments in the information communication technologies and computing services throughout the 1990s brought about dramatic transformations in the manner which organizations carry out supply chain and logistics operations as a way of maintaining an edge over competitors (Rell, 2013). To acquire competitive advantage organizations in the e-commerce sector ought to find a balance between price, timely delivery, and customer service and satisfaction. Logistics and supply chain activities in this sector rely on customer demand, and this leads them to adopt data management and storage tools, which fall in with AL aspects, such as enterprise sources of information, and information technology-based software to improve efficiency, platform effectiveness, and maximize the added net value (Kayikci, 2018).

Demand Sensing Technologies

This is exemplified by companies present in the sector, like Amazon, in their application of demand sensing technologies (Berttram, et al., 2018). Demand sensing technologies analyze data sourced from new digital forms of technology present in organizations to predict when and where potential clients will purchase a product, and in which quantity (Berttram, et al., 2018). The data sources are made up of the real-time signals and historical data present in a particular organization in this industry. Amazon uses demand sensing through its patented ‘anticipatory shipping’ system which is based on algorithms that trigger shipments even before a customer can place an order (Ulanoff, 2014).

Anticipatory Shipping Model

The anticipatory shipping model which was patented by Amazon in 2013 works by packaging more than one item as an order for an upcoming shipment to an address for delivery, picking a geographical destination for shipping the package, ship the package to the geographical destination region without fully identifying the address for delivery at the moment of shipment. The address for delivery gets fully defined while the package being delivered is in transit. The goal of anticipatory shipping is to add the number of orders which can be delivered in less than 24 hours (Sahiner, 2014). Anticipatory shipping builds on predictive analysis and big data and Amazon intends to use it to gain constructive insights for the prediction of what consumers wish to buy before they can even buy it. This works by first shipping the items to an Amazon hub that is present in the geographical region where the company believes the items will sell in the near future. This is illustrated in Fig. 1 below. This is an enhancement to the logistics of the business by rendering it unnecessary to wait for customer orders to be received to initiate the central warehouse activities of labeling packages, loading them, sending them using USPS or UPS before delivering them. As an advantage, by anticipating demand, Amazon can have faster deliveries. This will exponentially increase Amazon’s next-day and same-day number of deliveries. A disadvantage to the anticipation of demand by Amazon is the making of inaccurate orders (Deloitte, 2018). This is owing to the fact that big data and predictive analyses are still developing in the current world and this leaves room to comprehend that computers have not always been 100% accurate in predicting human needs (GTG Technology Group, LLC, 2015). Another advantage is that the volumes of sales are expected to increase despite the likelihood of inaccurate orders. The company is optimistic that a significant population of clients will buy the items and make a payment for them. Another disadvantage of making order predictions is that it may appear offensive and intrusive, this evoking ill-will among customers, causing them to refrain from buying their items from Amazon (GTG Technology Group, LLC, 2015).

Anticipatory shipping appears to be risky, especially with the consideration that there is a balance between the pros and cons, yet Amazon still opts to take it up. This high-reward and high risk model will supplement the implementation of anticipatory logistics, using anticipatory shipping ideals of continuous optimization, corporate agility, customer centricity and innovation culture (GTG Technology Group, LLC, 2015). To add, like the general activities involved in the implementation of anticipatory logistics, anticipatory shipping will be costly to implement. However, the expansive opportunities will result in other e-commerce organizations adopting it into their logistics systems as soon as it turns out to be successful (GTG Technology Group, LLC, 2015). This means that companies will approach Jeff Bezos, Amazon’s CEO, for valuable insights on anticipatory shipping. In addition to anticipatory shipping, other kinds of technology are developing in the e-commerce industry which appeals to anticipatory logistics. This includes the use of unmanned aerial vehicles, which has caught the attention of organizations like Amazon and DHL (which already putting UAVs into test in Germany) (GTG Technology Group, LLC, 2015). 3D-printing will develop to supplement anticipatory shipping and logistical procedures through on-the-spot production of small parts. 3D printing will also increase competition in the e-commerce market between the large organizations and the small- and medium-sized enterprises (SMEs) (GTG Technology Group, LLC, 2015).

Automotive Assembly

Anticipatory Logistics in Automotive Industry

The automotive industry is faced with the digitization of its processes, which is an upgrade to its conventional analog processes. Every aspect of its modern business, such as automotive assembly that was analog in the first placeis digitized, and this offers opportunities for disruption (NTT Innovation Institute Inc., n.d.). Big data and analytics are being used to facilitate improvements in supply chains in this industry by predicting demand. The reliance on data analytics in demand prediction also aids in minimizing risks and maximize growth resulting in an optimized supply chain system. Managers in the automotive industry use analytics to identify the right partners and vendors they should deal with (Deloitte LLP, 2015). They can identify the channels, which customers use to contact companies, optimize inventories and distribute products according to real-time demand.

Demand Driven Supply Chains

Companies like Toyota use advanced supply chain analytics and demand-driven supply chains in order to shift away from reactive models of the same functions. Advanced supply chain analytics allows Toyota to engage a proactive model of management by equipping the company with the ability to progressively forecast and respond to the industrial changes in the automotive assembly environment (The Economist, 2009). Toyota uses its demand-driven kanban system which adheres to the principles of just-in-time management of inventory and lean manufacturing (Budd, et al., 2012). The kanbanis representative of Toyota’s ‘pull’ approach to customer demand as a way of managing its network of materials, suppliers, and components of manufacturing and distribution.

Toyota Production System

Toyota also has a Toyota Production System, which is highly efficient which aids it in being able to appropriate planning of production and making accurate demand predictions. Demand prediction, particularly the demand for new model vehicles, is difficult in fast-growing automotive markets for Toyota, like China. At the end of every fiscal year, Toyota holds sales conventions by gathering the entire important sales representative in China. The conventions focus on collecting the replenishment plans for the upcoming year from the dealers which include a detailed number for certain automobile models, the total quantities, and the monthly configurations. This prompts Toyota to determine the quotas for the year for each dealer according to the figures they submit in the replenishment plans and the total number of sales from the previous year. This result in the appropriate development of a production plan for the year that follows and during its implementation, Toyota makes adjustments to the general production plan according to the sales realized. As a means of complying with the ideology of anticipatory logistics, Toyota uses these replenishment plans to develop quotas according to the level of demand recorded. The replenishment plans are regarded as effective tools in demand prediction. The implementation of anticipatory logistics ideas is facilitated by the organization’s centralized, multi-level structure of management. Upon realizing demand, trans-shipments are arranged between regions and sub-regions as dealers get to enjoy a certain degree of flexibility by informing the main organization about the replenishment plans at least three months earlier and the quantities can be adjusted by 10% until 2 months before delivery.

Self-Driving Vehicles

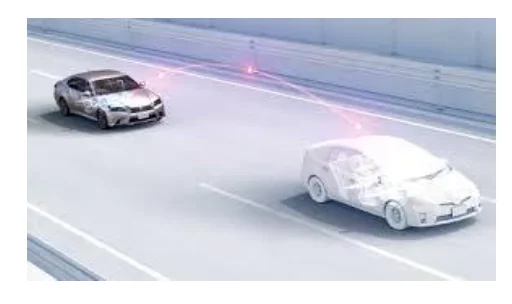

Apart from Toyota’s demand-driven kanban system, the automotive industry has been using advanced technology in the form of self-driving vehicles in logistics activities as illustrated in Fig () below. This because, separate from being used in the transportation of people, self-driving vehicles are useful in warehouses as well as other private, secure indoor areas where goods are loaded, transported and isolated relatively.

Self-driving vehicles are more useful in indoor locations than the outdoors where the conditions are harsh such that after long hours of work, tired drivers pose a huge risk. For several years, the automotive assembly has deployed self-driving technology on a degree that is quite higher than in other industries. By definition, the self-driving vehicles are those which operate without the direct input from a driver to control vehicle operations such as acceleration, steering, and braking. In this kind of vehicle, drivers need not to monitor the roadway consistently while the vehicle is on self-driving mode (Kuckelhaus, et al., 2015). These autonomous vehicles already bear sufficient technology that causes a vehicle to move from one point to another without any person being on board at all. Self-driving vehicles could be considered an idea that is possible yet far-fetched into the future, although, the reality is that the technology is already in use. Some of the world’s top technology and automotive firms have showcased prototypes and gone ahead to discuss self-driving vehicles with the theme of being the next revolution in the automobile industry (Kuckelhaus, et al., 2015). Among the benefits brought about by self-driving technology are high efficiency, improved safety, lower impact on the environment, and, for public users, greater comfort. The self-driving technology operates according to the interdependence between the functions of trajectory control, motion planning, situational analysis and navigation (Kuckelhaus, et al., 2015). Trajectory control ensures driving stability by managing the way pre-planned changes in direction and speed are performed by the acceleration and braking systems. Motion planning is useful in avoiding accident collisions with dynamic and stagnant objects by using sensors to monitor the movement of the vehicle. The monitoring is necessary in determining the precise pathway of motion for a specified period. It is helpful in ensuring the vehicle retains its lane and proceeds in the correct direction. Situation analysis uses video cameras to monitor the environment that the vehicle moves in and ensures that the autonomous system is wary of all the necessary objects and their motions (Kuckelhaus, et al., 2015). It is due to this functional feature that most self-driving vehicles are adopted in warehouse application. Navigation uses the global positioning systems (GPS) for essential planning of routes. This relies on the creating a map which is consistently recalculated to include information regarding road types, locations, settings, weather forecasts, and terrains (Kuckelhaus, et al., 2015). Predictive algorithms are used together with automated vehicles to enhance the flexibility of transport services by addressing the vehicle routing problem (van Engelen, et al., 2018). A combination of self-driving vehicles and demand predictive algorithms are useful in the performance of demand responsive services and adds essence to anticipatory logistics. The advantage of merging both technologies in the automotive industry is that they increase accessibility and service coverage in logistics (van Engelen, et al., 2018). Auto-manufacturers also benefit by achieving great flexibility and reducing operational costs. In fact, automated vehicles are preferred to and better suited than the traditional manual vehicles for public transport systems which are more responsive to demand. When working together as a unified system, the predictive algorithm and automated vehicles can result in the more effective and efficient deployment of transport services. One real-life application of predictive algorithms working together with automated vehicles to solve logistics problems is the online dynamic insertion algorithm that has demand forecasts being used with the rerouting of empty vehicles (van Engelen, et al., 2018). The system supports anticipatory logistics by making a decision, every time that a customer sends a request for being picked up, to select a vehicle having a higher residual capacity.

Food and Beverages

Anticipatory Logistics in Food and Beverages Industry

The food and beverage industry consists of exciting and fast-moving businesses. The businesses in this industry handle a combination of intangible and tangible products. For a long time, companies in this industry have focused on satisfying customers through quality assurance. However, with time, this approach of customer satisfaction has changed to consider the value added to the products, which clients may not have expected (Lockwood & Bowen, 2003). One way of adding value is by being able to predict demand and demand is key in this industry because it is prone to consistent fluctuations (Nguegan Ngeugan & Mafini, 2017). The unpredictability of customer preferences and demand is highly prevalent, and it affects the profits and successes made by existing businesses. In addition, goods in this industry are highly perishable (Lockwood & Bowen, 2003).

Sources of Uncertainty

Amount of Order Forecast Horizon

There are several other sources of uncertainty in the logistics activities in the food and beverages industry and one of them is the amount of the order forecast horizon which is the period between placing an order to the receiving of goods after the order has been made. This uncertainty in food and beverage industry renders it necessary for sales estimates to be made during the period of forecast horizons (Lewis & Naim, 1995). Two elements are distinguished in the amount of order forecast horizon, and they are the order sales period and order lead time. The order lead time represents the time which elapses from the time an order is placed up to the time of the receipt of the ordered goods. The order lead time has five elements, and they include the lead time for information (time required for the supplier to receive and process the order), the decision or administration process time (time required for the generation of a production plan and this is in the case of production to order, the applicable time required for production of the products, the lead time for distribution and the time for waiting between procedures (Lewis & Naim, 1995). The order sales period signifies the period between two deliveries that are made successfully. In the food and beverage industry, the order, which is followed by deliveries after an order lead time, needs to be huge enough to facilitate the sales during the order sales period (Beulens, et al., 1998). The long frequencies of delivery as well as the long lead times for orders could result in increased uncertainty which in turn causes high levels of safety inventory and many activities that do not add any value to the supply chains. In order to increase the potential of supply chain performance in the food and beverages industry, it would be worth to minimize the amount of order forecast horizon, and the addition of the order sales period and the order lead time (Beulens, et al., 1998).

Input Data

This is another source of uncertainty in the food and beverage industry, which has insufficient data for making decisions. The transparency and availability of information in the supply chain can potentially reduce costs in a radical manner and increase service for customers. One study by van der Duyn (1994) revealed that information regarding the upcoming production runs status which is provided by a supplier who makes orders in production cycles which are fixed allows a retailer to minimize the inventory costs by nearly 30% as they still fulfill service requirements and constraints (van der Duyn, et al., 1994). Data applicability and data timeliness need to exist prior to the exchange of information. The control systems for inventories ought to be updated and managed properly so as to provide existing information on stock availability and stock levels (Lewis & Naim, 1995). In case the control systems are not managed well and updated, the total consideration time frame grows even larger. In addition, information regarding consumer demand has to be presented in the correct format essentially for eliminating problems of translation. When producers receive all the sales data of a particular group of product they would want to know how much of each specific product have been sold so that they can plan their production accordingly. Similarly, a tomato supplier for a salad producer does not need data regarding consumer demand of salads in the outlets of retailers if they cannot possibly translate them to the quantities of tomatoes; especially when they are not the only tomato supplier for that specific producer. In the end, making data specifications can become a pivotal point for uncertainty. In an investigation which sought to identify whether or not the bullwhip effect logic could be applied to different parts of the package of information like understanding customer dissatisfaction/satisfaction, performance, or understanding customer expectations (Beulens, et al., 1998).

Decision and Administrative Processes

Human behavior, according to Beulens (1998) is influenced by decision policies. Sub-optimization occurs because of the application of production and ordering rules with fixed sizes of batches, comparing local services provided and internal costs at specific points in time, and use of local inventory and demand information. The aggregation or ignoring of information in decision or administrative policies creates additional uncertainty (Beulens, et al., 1998).

Inherent Uncertainty in Demand

Inherent uncertainty in demand is a crucial source of variation in the food and beverages industry. This is because, as Beulens (1998) brings to focus, even when the consumer average demand is well known, it is subject to changes resulting from variations like changes in weather, and changes in customer preferences. Inherent uncertainty of processes refers to the fluctuating outcomes of the processes and times of production as a result of the yield of variables from processes. The marginal increase of downstream and upstream exchange of information can result in the elimination of the impact of inherent uncertainty in supply chain patterns. The main benefits of a food and beverages company supply chain are acquired by reducing other sources of uncertainty. This brings about the need for time series analysis in making forecasts (Beulens, et al., 1998). Therefore, several models have been developed, relying on the concept of time-series analysis to forecast demand and minimize the perishability of products. The methods of forecasting used depend on arithmetic models which use historical data, and qualitative processes which are planned according to customer reviews and administrative experiences. Some of the forecasting methods include the exponential smoothing models, which rely on the smoothing of historical data in a time series, and simple exponential smoothing models, which rely on weighted moving averages (Barbosa, et al., 2015). There exists limited literature regarding general demand forecasting in the food and beverage industry. Despite this, out of the few material that were found, one study that was carried out by Hu, Chen, and McCain (2008) illustrated how occupancy data could be used to forecast demand in a buffet restaurant for a casino. However, the occupancy data, which was taken through a regression model proved to be unreliable due to problems of redundancy (Hu, Chen, & McCain, 2008). A company which has successfully implemented forecasting models and enhanced its predictive accuracy in this industry is Nestle. Nestle adopts the SAS demand-driven forecasting solutions which have proven to be effective in minimizing inventories, exceeding original projections, creating synergy between planning and sales, and the achievement of a lasting return on its investments (Nestle, 2018).

Clothing Manufacturing Industry

Anticipatory Logistics in Clothing Manufacturing Industry

At first, reactive models of anticipating demand for products were used in the clothing manufacturing industry. Indeed, this had great negative impacts on the supply chain and logistics processes of firms in this industry (Liu, 2018). For instance, some of the defects that were present in the supply chain operations of clothing retailers included an imperfect system for tracing product information, lack of coherence between supply and demand, inability of supply chain to respond fast enough to changes in the market, and there was serious backlog and shortage of inventory. The imperfect system for tracing product information was characterized with incomplete information concerning the origin of clothing and surface materials, and the dyeing processes. The lack of coherence between the supply and demand was due to lack of smooth information of demand (Liu, 2018). Thus, it was difficult for enterprises in the upstream to grasp the demand information in the downstream market accurately and it led to the supply chain makers; manufacturing and design links failing to grasp the market demand accurately. Eventually a mismatch between demand and supply in the supply chains occurred. The inability of supply chain to respond fast enough to changes in the market was accounted for by the inability for firms in the upstream market to grasp the demand information of the downstream market (Liu, 2018). The serious backlogging and shortage of inventory was as a result of the complex nature of the cycles of the clothing industry. For example, under the bullwhip effect of the supply chain, information about demand is usually distorted and this results in the engulfing and backlogging of profit from the supply chain. The apparel industry is bombarded with problems like insufficient historical information and seasonal trends, and demand uncertainty. Poor prediction among apparel companies occasionally results in high inventory, stock-outs, low levels of service, rush orders, obsolescence, bullwhip propagation by the upstream chain of supply and poor utilization of resources (Giustiniano, et al., 2013). The fashion industry products are characterized with short selling seasons, the long lead time for replenishment, hard-to-predict demand and, therefore, incorrect forecasts (Syntetos & Boylan, 2001). To add, customer preferences and tastes change dynamically, and companies are expected to meet these requirements both at the service and product level. The sales specify in the clothing sector complicate the forecasting process in this industry. Long term forecasts are very much needed in the incompressible and long shipping and manufacturing lead times in the clothing industry.

The long term forecasts take into account different clothing particularities such as the strong relationship between the weather and most garments which make the sales very seasonal. It is possible to acquire general trends using seasonal data but unpredictable variations are likely to bring about critical hollows and peaks. Many variables which are exogenous in nature disturb sales. These variables include consumers’ purchasing power and sales promotion. Customer demands are highly volatile in this industry due to fashion trends. The style and design in fashion trends have to be always up to date and most of this impacts the lack of historical sales. Another particularity of the clothing industry is that there the items are left without being renewed for the following collection. The items are ephemeral and are a huge variance of products. Different color alternatives have to be provided so as to meet the trends in fashion and in several sizes which will resemble the target customer morphologies.

Demand Forecasting Tools

The particularities serve as the complex and specific constraints for sales forecasting in the apparel manufacture industry. Implementing demand forecasting tools to aid in logistics in this field requires sufficient knowledge in sales forecasting and a complete subtle knowledge of the challenges and operations present in the supply chain of the clothing industry. For instance, it would be worthy to understand that the customer demands are highly volatile due to the unfaithful nature of consumers and they generally base their decision to buy clothes on their prices (Choi, 2007). This constraint causes apparel makers to rethink their manufacturing and in-bound logistic activities by making efforts to minimize their costs of production and maintaining high levels of service. This causes a large proportion of manufacturing activities to be done abroad in nations where the costs of production are much lower. Optimization of supply chain management activities have to be done as a way avoiding delays, running out of stock, unsold inventory and maintaining the right levels of inventory (Choi, 2007). The synchronizing and scheduling of the flow of information and materials can be done using several tools for supply chain management (Sen, 2008). A great number of the tools can be customized to suit the particular constraints of the apparel industry and it remains that the degrees of efficiency shall depend on the ability to make accurate sales forecasts. This knowledge is also very sensitive to the type of environment which an organization is based in the fashion industry. Furthermore, to implement good demand forecasting tools for the management of supply chain activities, it is imperative that knowledge about the sales features; the products and the manner in which distributors use forecasts have to be perfect. Several forecasting methods are adopted with the goal of linking the approaches used with the market characteristics. Big data solutions are adopted by enterprises in the clothing manufacturing industry, whereby big data technology is used in performing in-depth mining and analyzing a the design chain for a product, the manufacturing activities, logistics and procurement as well as other aspects of the management of supply chains. The big data allows each of the links to be used in the adjustment of demand using big data analysis, optimization of the networks of supply chain and, ultimately, improve the competitiveness of the whole chain of supply (Liu, 2018). Commonly, high performing apparel manufacturers, such as Giorgio Armani, have developed robust approaches for predicting demand (Moisanen, 2014). Digital techniques such as Artificial Intelligence (AI) and Augmented Reality (AR) are taken up by apparel makers such as Giorgio Armani to control demand by being able to personalize customer experience, widen product experience, broaden its audience, and cultivate strong relationships with clients (Deloitte, 2018). Since it is difficult to predict demand due to lumpiness and short selling seasons, Armani uses AR and AI technology to influence demand. For example, AI-driven recommendations can be used to influence consumer decisions, by making them reliant on advice and suggestions provided by company devices, rather than making decisions according to their personal experience (Deloitte LLP, 2015). Additionally, the fashion industry is equipped with forecasting methods which rely on time series analysis to predict sales. Some of the statistical techniques used have popular models which have statistical foundations which are formal. These statistical foundations include the Box & Jenkins model, regression models, exponential smoothing, Holt Winter’s Model and ARIMA (Papalexopoulos & Hesterberg, 1990). When implemented in different areas, these techniques have remarkable results. Their efficiency tends to rely on the forecast goal, user experience, and the application field (Armstrong, 2001). These methods are not efficiently or easily implemented in the fashion industry because large historical data is required yet the fashion industry lacks it (Papalexopoulos & Hesterberg, 1990). When designing a model for forecasting, the most important parameter to be used in the fashion industry in the historical data available.

The previously discussed statistical models are the foundation of commercial systems of forecasting in the fashion industry. The operators can chose suitable methods automatically using the chosen set of data. The Holt Winters, Box & Jenkins, and the regression methods are put into application in different software like Forecast Pro of the BFS, SmartForecastsof the SmartSoftware and the Autoboxof AFS (Thomassey, n.d.). There is a small number of software which use the advanced techniques of computing, especially those of neural networks. Over the previous decade, forecasting tools are implemented to integrated software like the ERP, which includes the TXT-Demand planning of the TXT group (TXT Retail, 2015). Some firms have proposed systems which are specified for the fashion and the apparel industry such as Forecast Management of the Demand Solutions firm. Sales forecasting has constraints which have been previously mentioned on the paper and it is important to have forecasting accuracy, especially for forecasting products. Implementing advanced techniques of forecasting can be analyzed according to different levels. One level is the reducing the bull-whip effect without having a major reorganization of the supply chain. A second level is the possibility for the production process to be smoothed out by a supplier as well as decreasing their costs, optimizing their resources and improving the effectiveness of the sourcing strategy of retailers. The third level is the amount of markdowns and lost sales which have been reduced, and eventually resulting in an increased margin of profits (Mattila, et al., 2002).

Pharmaceutical Industry

Anticipatory Logistics in Pharmaceutical Industry

The pharmaceutical industry is characterized by expectations from doctors, patents and insurance companies, market power which is determined by brand loyalty and patent protection, the availability of drugs, uncertainty of illnesses and their cure, and choices made by practitioners according to health and industrial policies. Planning in the pharmaceutical industry resonates on demand forecasting. The objective of demand forecasting is to determine the products which will be bought by consumers, their quantities, where and when they shall be bought. In more developed pharmaceutical markets, there is vast amount of information and balanced market power. The pharmaceutical industry is different from other sectors where gathering the condition of forecasting, the systematic sharing of available information, and demand scenarios develop without the influence of political dynamics with the highest accuracy (Candan, et al., 2014). This is because; pharmaceutical companies are close in their relationships with patient pharmacies, doctors, and lawyers. Manufacture of drugs ought to be according to the regulations developed by the Good Manufacturing Process (GMP) and the Food and Drug Administration (FDA).

New Drug Development

In order to compete with the modern economy challenges, pharmaceutical companies make numerous changes. Supply chains and manufacturing management affect new drug development. The growth in several global economies can be attributed to by the pharmaceutical industry by offering the global population the cure and alleviation from different kinds of epidemics. Pharmaceutical companies manufacture drugs for the purpose of gaining profits (Candan, et al., 2014). However, economic and political relations affect their forecasting techniques. Demand for pharmaceutical products is based on the derived benefits of the drugs, rather than the value of the products provided. The demand is also directed since patients have no alternative but to take drugs specifically prescribed by doctors. The demand for different pharmaceutical drugs is sensitive to differences in quality thus leading to high levels of product differentiation. The goal of the differentiation is to make firm the brand loyalties and set up a market that is more secure for both the drug and the company.

Internet of Things

Big pharmaceutical companies rely on the internet of things (IoT) to determine the trends of their drugs in terms of demand and anticipatory logistics. The Internet of Things is defined as the network of mobile physical devices and other tools which are integrated with electronics, sensors, network connectivity and software which enable them to collect, store and exchange information. It is projected that 40% of all IoT kinds of technology will be related to health creating a market that is worth $117 billion (Bauer, et al., 2016). IoT was integrated with medicine because pharmaceutical companies realized that in order to achieve sustained growth and competitiveness; they would have to engage in more than just selling conventional medicine. This is owing to realizations which where patient care extends beyond the use of medicinal drugs alone. Some of the realization are that patients do not achieve the optimal care outcomes from drugs alone, and pharmaceutical companies are losing track in the market due to the ‘beyond the pill’ firms gaining track as viable revenue sources (Landwehr, 2015). As a result, the concept of PharmaIoT grew which involved digitizing medical products are related processes of care using medical devices, which are smart connected and IT services such as mobile apps and the web, during the development of drugs, patient care and setting up clinical trials. PharmaIoT allows healthcare professionals and patients to utilize medicine using hardware with advanced sensors and set up more personalized services in health care and processes. For example, PharmaIoT solutions are used in the connected wearable sensors for Parkinson’s disease and patients with multiple sclerosis that provide management of medication resulting in improved patient quality of life and patient outcome(van Uem, et al., n.d.). To add medical device products which are already existent like insulin pens and inhalers can be added to connectivity technologies and sensors to facilitate data collection for analytics for future care and more personalized therapy. This, as a whole, results in improved personal care and medication procedures because data for patient care present new opportunities for competitiveness and innovation.

Although, when using PharmaIoT, some challenges need to be taken into consideration, such as the European Union data privacy and protection legislation which grant patients the control over their healthcare information. For instance, patients have the freedom to transfer their information to different service providers which results in the emergence of new business models (such as data brokers on big Pharmaceutical industry) and entirely new kinds of platforms of service. PharmaIoT is crucial in the anticipatory logistics activities by companies in the industry because it presents an age where information, data and knowledge are very important. With the influence of technology, the pharmaceutical industry will be affects with the age of information where customers can easily determine what they require for treatment, and in this case, the drugs that shall be used. Business models are changing to making direct links to drug manufacturers (MyTomorrows, 2016). Typically, drug manufacturers maintain high level of efficiency in the manufacture of their drugs for some economic reasons. Patients find it important for more than one dose to be produced. Pharmaceutical development also considers factors of gender and sex, and marketing. Automated Guided Vehicle (AGV) systems were proposed as an approach in solving problems related to dispatch (Confessore, et al., 2011). The AGV was modeled into a network through the reliance on the Minimum Cost Flow Problem formulation (Alizadeh, et al., 2012). The minimum cost flow problem is exploited in the optimization of the performance of the AGV in the production system of pharmacies. The locally linear fuzzy (LLNF) inference together with the emotional learning fuzzy inference systems (ELFIS) are the two models which are set up in the prediction and simulation of systems which are complex and dynamic (Alizadeh, et al., 2012). The models are also useful in the prediction of stock prices in individual pharmaceutical companies. The driving force behind the PharmaIoT, such as the wearable sensors, is the data volume that is generated and various drug makers are trying to collect and store the data streams as a means of reining in. Some of the means of bundling the data stream is through Microsoft’s Health Vault which is regarded as an e-health safe that assumes the qualities of an EMR (Auffray, et al., 2016). The Radbound University Medical Center, in collaboration with Sales force and Philips, in Holland, developed HereisMyDatadatabase which stores patients’ data concerning their health and giving them the authority to determine who will access that information. Sale force has an important role. As a platform which powers Veeva, a customer relationship management tool widely used in the pharmaceutical industry, Sales force works as vital link between the drug manufacturers and medical data. In the pharmaceutical industry, the phrase big data is defined according to three V’s – Volume, Variety, and Velocity (Auffray, et al., 2016). Volume is concerned with the large amount of data, variety is concerned with the heterogeneous nature of the type of data, and velocity is concerned with the speed at which any user apart from a data scientist can use to analyze after accessing the data (Auffray, et al., 2016).

Demand Forecasting Methodologies

Therefore, various forecasting methodologies are developed with regard to the nature of demand in the pharmaceutical industry along with the collection of the large amount of data. Some of the forecasting methodologies used include the morbidity method and consumption method. The consumption method uses historical information about previous consumption patterns to forecast future demand. Simple extrapolation is used by drug companies which have their products already well-established in a market that is stable which works by projecting the current trends into the future (Johnson, 2018). Drug companies such as GlaxoSmithKline use a decision support system to aid making forecasts at the stock-keeping unit level and setting up plans for replenishments which relies on the traditional techniques of inventory management as well as the interaction of these techniques (Shang, et al., 2008). The decision support system manipulates input data such as lot size, lead time, the time period for historical information and monthly predictions for a GSK product to acquire specified levels of service through optimal results (Shang, et al., 2008).

Theoretical Background of Anticipatory Logistics

Technological advancement is part of the most distinctive features of today’s ever-changing world. It is becoming more evident that the dynamic nature of the existing logistics environment cannot be supported by the present system of supply which relies on reactive procedures which tend to be manually intensive. The reactive procedures lack the potential of meeting the changing needs in a dynamic logistics and supply chain environment (Machese, 2014). The ability to learn and master new trends in the market proves to be a strong differentiator for competition in the logistics environment. Disruptive technologies are increasingly gaining relevance due to their ability to enhance such mastery by developing new business models which potentially displace the current reactive processes (Bubner, et al., 2016). Having recognized the enthralling nature of new trends in the logistics environment, an annual report issued by a German group of researchers titled Logistics Trend Radar is representative of the efforts that visionary managers ought to take by considering the ability of innovative technologies to exceed consumers’ current needs in order to improve performance in different levels and activities regarding logistics and supply chain (Bubner, et al., 2016). The report aggregated different views expressed by the general business community and academia, in conjunction with the data presented by DHL, expertise in the provision of logistics on a global perspective to suggest trends which are likely to develop in the logistics environment. These trends are predicted to have a maximum five-year impact on the logistics industry (Machese, 2014). Among the suggested trends is anticipatory logistics, which uses predictive algorithms which rely on big data. Anticipatory logistics represents the improved techniques for predicting the material requirements of logistics, which are primarily used in military operations. Simply put, AL uses predictive algorithms in efforts of anticipating demand (Angeleau, 2016). AL uses communication and technology together with improved data in enhancing the predictive power of the existing systems, making them more accurate and responsive in the supply systems. In addition, AL significantly boosts the efficiency of processes and quality of service by enabling the prediction of demand before its actual occurrence as a means of achieving faster and shorter delivery times and enhanced network and capacity utilization (DHL Trend Research, 2015). Anticipatory logistics is propelled by the increasing customer demands for lead times which are shorter from the time of order to the point of delivery. Before applying AL, retailers try to anticipate their demand (KPMG International, 2016). The Internet of Things is a prime enabler of predictive maintenance in the industrial context by its application using intelligent vehicles and machines which have the capability of predicting maintenance and logistic needs (Angeleau, 2016). Anticipatory shipping is one of the AL models adopted by Amazon in the e-commerce sector. Just like Amazon, anticipatory shipping is adopted by online retailers after doing an analysis of the buying patterns and behaviour of customers to predict what they will order before they actually do so. This model allows retailers to move their products to centers of distribution which are closer to clients who are more likely to buy them (Angeleau, 2016). It is very effective in minimizing lead time by allowing retailers to offer one-hour deliveries or even same-day services. Future progress will result in the collaboration between shipping based on predictions and the tradition delivery of orders based on shipments, even though it may remain challenging to integrate both techniques simultaneously in the supply chain networks.

The monitoring of intelligent assets such as vehicles and machines in real time will provide data used for predictive maintenance. Predictive maintenance is beneficial in reducing the downtime for customers and logistics providers. The smart assets will also aid in anticipation of the logistics of spare parts. For instance, heavy machine components have general wear which can be predicted with time so as to facilitate the delivery of replacements at the right place and at the right time. The prediction of risk in supply chain management is a useful feature of AL which supports a logistics provider to detect potential damages on cargo (such as monitoring shock movements) and risks on trade lanes in order to minimize operational delays and engage corrective action (Berttram, et al., 2018). The smart planning of capacity by the utilization of anticipatory algorithms can be adapted to match the correct levels of resources of logistics to meet and satisfy demand. For example, smart capacity planning can be used in making accurate predictions of the required capacity of logistics during peak seasons of shopping (Bubner, et al., 2016). The central opportunities presented by AL include the increase of customer satisfaction by improving the order-to-delivery experience, allowing accurate demand prediction for lean management of inventory, and improving planning precision for efficient utilization of capacity and resources. The main challenges brought about by AL include the scarcity of resources and skills to handle and understand the advanced tools and methods of analytics, the complex and costly analyses of big data, compliance issues regarding privacy regulations and data security (such as the ethics involved with online tracking of customer behavior), and the requirement of open exchange of data between customers and logistics providers in facilitating anticipatory services(Berttram, et al., 2018).

Similarities of anticipatory logistics applied in manufacturing sectors in different businesses

As aforementioned, AL works by using predictive algorithms in efforts of anticipating demand. Big data analytics is adopted in the manufacturing sectors to facilitate the forecasting of demand for products (Bubner, et al., 2016). The primary goal is to predict demand, when, and where it will occur before customers place their actual orders. This boosts service quality and efficiency. Digital technologies have the capabilities of collecting large quantities of data, and computer algorithms developed to manipulate and analyze the big data to come up with demand projections (Bubner, et al., 2016). Generally, AL presents useful methods and techniques of forecasting demand, which possess similar characteristics in the manufacturing sector and other industries. The similarity in characteristics of AL technologies being adopted in different industries will be discussed in this section. Since AL is forward-looking, the similarities observed in industries can be identified using various shared forecasting methods for customer demand. Logistics providers are presented with an array of forecasting techniques and methods, which are well established, and they all adopt basic techniques in predicting demand.

Qualitative Techniques

AL models in manufacturing industries, such as fashion and design, rely on quantitative techniques. This is efficient in the contexts where historical data is very limited and managerial judgment is necessary for making predictions (Moisanen, 2014). However, these techniques tend to be half-efficient and half-effective because they rely on managerial anticipation of demand without sufficient data analysis. It is also costly due to its reliance on high expertise and a lot of time is take in the collection of opinionated information through panels, consensus meetings, and surveys (Moisanen, 2014).

Time series Techniques

This technique, which is similar to anticipatory shipping adopted by Amazon, uses statistical procedures when historical sales information has a relatively stable and clear relationship and has trends available (Moisanen, 2014). The time series methods of forecasting are quantitative in nature because they rely on figures recorded at regular intervals of time. By looking at sales history, time series analysis identifies cyclic trends and patterns and seasonality. Upon realizing the individual components of forecasting, techniques using time series will make future projections by assuming that past demand will progress into the future. A variety of methods based on time-series analyze the movements and patterns of historical data to come up with recurrent characteristics (Moisanen, 2014). The two commonly used methods based on time series analysis include moving averages and exponential smoothing (used in food and beverages industry).

Causal Techniques

These kinds of forecasting techniques forecast by regression. Casual forecasting techniques use quantitative methods to analyze and evaluate the cause-and-effect links between more than one variable. Typically, one variable’s cause and effect on another variable are investigated in the determination of factors such as advertising, changes in price, other than demand (Moisanen, 2014). First, data is collected for the underlying variables of focus then regression is used to approximate the quantitative impact of the independent explanatory variables on the dependent target variables. If a single factor is used in the cause-and-effect regression analysis of a scenario, then it is referred to as simple regression. If two or more explanatory variable factors are used in the analysis, then it is called multiple regressions. In demand forecasting, a correlation has to exist between sales and the preceding explanatory independent variable, like the sale of related complementary goods (Moisanen, 2014). This technique is similar to those adopted by drug companies such as GlaxoSmithKline, through its decision support system.

Holistic Model Based on the Differences between Anticipatory Logistics and Supply Chain Management

In every industry, organizations compete to acquire the largest portion of the market share, which is contributed by the target customers in those markets. In order to attract customers, organizations ought to consider customer value through product pricing, the lead time for deliveries, psychological acceptance of goods and other efforts which can be done to increase product value. This necessitates supply chain management in organizations present in global industries so as to manage the flow of their products and service in a manner which customers demand (Sahiner, 2014). Current supply chain systems, however, are regarded as reactive in nature which islabour intensive and lack the ability to meet the changing needed of the dynamic environment of logistics. To fulfill what supply chain management is incapable of; anticipatory logistics is in existence, which is an enhanced way of forecasting logistics material (Sahiner, 2014).

Anticipatory Logistics in the Holistic Model

Anticipatory logistics is hailed for its forward-looking nature, and even though it may be new in the business world, it was already in use by the military through a C4I model, which represent control, computer, communication, command, and intelligence (Sahiner, 2014). It works by anticipating demand before it actually occurs so that supply chain management processes can be used effectively and efficiently for timely delivery (Sahiner, 2014). Anticipatory logistics has grown into an authoritative business model which anticipates the demands to be made by customers in the future. It is dominant because it is an intersection of anticipation of demand and information technology in the contemporary world. Anticipatory logistics consists information that forecasts customers’ requirements to provoke suppliers to produce and prepare services adequately in order to fulfill them. AL relies on analysis of data concerning product searches by customers, wish-lists, shopping histories, and even computer movements by the cursor so as to have a shipment sent before a client places their order (Sahiner, 2014).

Upgrading of Technology for AL

Many companies have supply chains and they are critical to their order deliver processes. Together with anticipatory logistics, companies can manage their supply chains in such a way that services and products are in direct proportion to the demands made by customers. A holistic model of AL and supply chain will help companies maintain a stronghold over production, internal inventories, distribution and their sales. In order to do so, companies ought to upgrade their Information Technology infrastructure such that they adopt the contemporary state-of-the-art scalable, future-oriented and flexible solutions which can aid in the implementation of anticipatory logistics. Upgrading of IT infrastructure is necessary for every organization because anticipatory logistics presents modern solutions to modern problems and complexities in the market. AL enlivens, customizes and simplifies the experience of the new-age tech-savvy customers. Nearly 86% of the customers today prefer to have delivery as part of their experience for online shopping, be it in the automotive manufacture, pharmaceutical, food and beverage, and clothing industries (FarEye, 2019). As discussed above, these industries adopt technologies which are smarter in different touch-points and they delight customers in several ways possible. Considering industrial differences, every organization has their unique set of requirements and there is no standard ready-to-use solution, or software which can facilitate all of the business requirements. Organizations are required to have the correct technologies to meet the demands of their customers. In situations where organizations cannot acquire the right technology for the sake of AL, they seek out for technology partners to whom they can rely upon in the augmentation of delivering the value, which their brands promise and experience to customers (FarEye, 2019).

Push and Pull System of Production in AL and Supply Chain Management

In light of the development of a holistic model based on the differences between AL and supply chain management, it is key to consider the corporate strategies of push and pull systems. The pull and push corporate strategies present solutions which turn out to be alternatives which can be applied in different industries with different logics which underpin the link between an organization and its final demand. The push system of manufacture corresponds with the ‘make to stock’ means of production where production does not rely on actual demand (Asprova Corporation, 2008). The push system is a corporate strategy which stands for the development of procedures and operations which originate from the company going out into the market. This illustrates its responsive qualities. In this context, a company will prepare goods by means of production and, using predictive information acquired concerning the market, they lead the goods to find the destined purchasers. Therefore, it is the company which sustains the supply of the product. The pull system of manufacture corresponds with the ‘make to order’ means of manufacture where production is based on actual demand (Asprova Corporation, 2008). The pull system is a corporate strategy, which can be considered as the opposite of the push system, as it refers to the procedures which begin from the market going into the company. Anticipatory logistics is representative of the push system of manufacture and distribution where inventory and production decisions rely on demand forecasts (Mazahir, et al., 2011). The fact that the push system leads to the initiation of supply from within a company heading out to the market is an illustration of its responsive characteristics which is coherent with the aim and quality of anticipatory logistics to predict demand before it happens. Supply chain management is representative of the pull systems of distribution whereby demand information (customer orders) is crucial in beginning manufacturing processes. The fact that the pull system results to the initiation of supply as a response to the pulling demand is an illustration of its reactionary characteristics which are coherent with the supply chain management processes which only rely on the incidence of demand. AL predictions (push system) serve to replenish supply chains basing on information from future predictions, while supply chain management (pull system) delays the final stages of production process until orders are received from customers (Mazahir, et al., 2011).

Holistic Model

A holistic model can be developed based on the differences of AL and supply chain management systems in the implementation of AL through a push-pull system, which merges the economies of scale acquired from the AL with the benefits of reduced levels of inventory and increased responsiveness from supply chain management. AL will contribute global-based information and forecasts while supply chain management will introduce local-based information into the model (Pyke, 1990).

Why the Push and Pull Strategy

It would be necessary to illustrate some of the factors, which justify the use of the concept of the push-pull strategy in developing a holistic model using the differences between AL and supply chain management. In doing so, it would be much easier to comprehend the model and possibly apply it in different industries in the real world. The push and pull corporate strategies are alternatives whose foundation is according to the different assumptions concerning particular markets. These assumptions consider the demand characteristics, the nature of competition, the system of finance and the system of suppliers among other factors in an industry that command different resources and capabilities from organizations. The push strategies, notes Sarbjit (2017), require good knowledge of the market and the needs of key players and their dynamics. The needs of the key players include the forces of competition and demand (Sarbjit, 2017). With the knowledge of these needs, it becomes possible to plan in advance the necessary corporate activities in performing the processes which are geared towards realizing a product for the company to strive to have good financial results. The AL is in coherence with the push strategy because it requires predictive knowledge of the market so as to plan logistics and supply chain activities in advance in order to achieve order delivery within the shortest lead time and maximizing on customer satisfaction. For its application, the premise is that a stable situation whereby corporate procedures such as communications and manufacturing can be successfully reiterated. Push strategies, alike AL, base competitiveness on the experience that is accumulated, which is built up on the same actions, which are repeated in time, also on a broad range of activities where the stable context allows the ease of exploitation and organization (Corniani, 2008). In this case, the stable context in AL is the industry in which an organization operates – an industry which is well-defined and data regarding consumer demand has been collected well over a period of time enough to identify patterns and make forecasts. The push strategy an organization can achieve economies of experience and of scale which develop cost structures which could be rigid but difficult to be emulated by competitors. For example, Amazon’s anticipatory shipping model grants the organization economies of scale and of experience (Machese, 2014). Even though it could be expensive to set up drones and other logistic activities ahead of the orders being placed by customers, it is difficult for Amazon’s competitors to emulate the model.

The pull system is based on an alternate premise. It is founded on the idea that an organization cannot acquire comprehensive knowledge concerning the market and the key players due to the dynamism and changeability of their needs and actions. This leads to the riskiness and limited planning corporate activities over an extended period. The pull strategy, therefore, is best applicable in an unstable context whereby the same corporate procedures cannot be successfully reiterated. The competitiveness of firms, in this case, is not based on the rigid cost structures, which are developed and tend to reduce with time (Martin, 2005). The competitiveness of a market under this strategy relies on the ability to engage rapid action in response to changes in the market. Experience will not be developed according to communications and manufacturing, instead, it is developed from experiences of flexible and rapid responses both according to communication and information, and to the processes of manufacture. This is the case of the supply chain management where reactionary measures are taken in response to the dynamics of a market.

Push and Pull Strategies and Technological Evolution

An important facet of corporate governance involves the identification of the decoupling point with regards to incessant business practices such as manufacturing, information and communication. The decoupling point may be defined as the point where the push and pull strategies converge. It is the point at which premeditated events which bear a definite risk outline are overtaken by undeveloped events with a diverse risk outline. The decoupling point could serve as the feature where the AL and supply chain management practices converge. A pull strategy is initiated by an order from a customer and in logistics, the decoupling point is usually referred to as the Customer Order Decoupling Point, and is the point at which the customer’s order is received within the firm, with the implication that a particular production or assembly process committed to the order is generated (Shidpour, et al., 2014). Practically, it determines the time at which business activities concentrate on the personalized response to the customer order received. The importance of this point with regards to anticipatory logistic activities lies in the fact that it describes operative materials handling methods such as stocks, manufacturing, assembly, and also regulates the advent of particular expenses devoted to each order received (Hou & Wang, 2016). In anticipatory logistics, it is recommended that the decoupling point be pushed forward as much as possible by delaying the events required to fill a particular order, where an approach which favours push activities is used. This would ensure that certain risks involving company-market relations such as bankrupt customers and changes to current orders are avoided (Olhager, 2010). The deferment principle is a cautionary strategy used to protect the company in the implementation of every event to respond to demand in a flexible way. Customization postponement makes it necessary for many businesses to introduce fundamental alterations in the manufacturing process so that the product is supplied in a more generic form and customization such as coloring and assembly is introduced at a later stage (Yang & Li, 2016). The Smart is a city car which has been common since the late 1990s and is manufactured by a supply chain which is reactive, designed with a multifaceted coordination of suppliers and sub-suppliers, which gives Micro Compact Car Smart Gmbh the ability to reduce (to 6%) any production activities done in-house and to enhance the assembly system of parts manufactured by third parties with coordinated production and distributions. Hence, it considerably decreases heaps of both finished products and parts and reacting faster to market demands with a small number of alternatives. The assembly begins from two rudimentary models: a grey chassis and a black chassis which don’t foresee many distinguishing accessories. The bodywork is put together directly on the final customer’s order, in some cases at the dealership (Warren, et al., 2001).

Alternatively, pushing forward the decoupling point and ignoring or failing to reply to a particular order, has certain cost implications on the business; for instance, costs related to heaps of finished products or parts for assembly (Xiaoxun & Jiajun, 2016). The necessity to build up stocks is considerably reduced when the decoupling point is postponed since more production activities and goods handling processes are committed to filling a definite order (Xiaoxun & Jiajun, 2016). Improving the decoupling point together with the manufacturing and goods handling process therefore predicts the customization of events, thus diminishing the necessity to make conceivable flexible state of affairs, since they are already available. Advancing the decoupling point results into the transformation of indirect costs into direct costs, until integrating them into the response to a particular customer is impossible. The need to keep the availability of goods, human and manufacture resources which are intended to basically ensure flexibility and responsiveness to volatile market response is condensed through the logical and chronological anticipation of the point at which the direct and indirect costs are addressed to please a specific customer (Xiaoxun & Jiajun, 2016). Push strategies are usually suited to the first processes such as those which are given first priority in the value chain, whereas pull strategies are often more suitable for the eventual processes, such as those that enhance the company-market relation (Birhanu, et al., 2014). Whereas determination of the decoupling point seems easier for tangible processes connected to manufacturing activities, the same cannot be said of information and communication processes since their intangibility and the availability of advanced ICT technologies makes it possible to switch between push and pull strategies in a more flexible manner with regards to the chronology of individual processes (Krishnamurthy, et al., 2001). Push and pull strategies allow corporate processes related to both tangible assets such as raw materials and finished products and intangible assets such as business information and communication to be put in place (Krishnamurthy, et al., 2001). The management of tangible assets translates to the flow of materials along the supply chain from the procurement of materials and components to their introduction to the manufacturing process or distribution process for manufacturing and marketing companies respectively, down until the finished product is delivered to the last person in the supply chain. Management of intangible flows of business information and communication may be treated in a similar way as tangible assets (Rodriguez, et al., 2007). The close connection between tangible assets and the flows of information and communication makes it possible for them to be jointly analysed usually using the same logical correlations. There exist at least two decoupling points in real supply chain. The first one being having been previously described as being the decoupling point of the materials where strategic stock are kept as original as possible. Taking into consideration the traditional economic criteria, this point should be as near to the end of the supply chain as possible; close to the final market. The second decoupling point is the point ofinformation which should be at the beginning of the supply chain and probably the highest point at which the information on the actual final demand enter the supply chain (Mason-Jones & Towill, 1999). Moving the decoupling point up the supply chain is motivated by the need to keep the implications of information distortion which arise from the flow of information in the supply chain to a minimum, a factor known as the ‘bullwhip’ or ‘Forrester’ effect (Mason-Jones & Towill, 1999).

The flow of tangible assets is often associated with a lot of information flows. On one side, material flow is the same as that of the information related to tangible assets processes such as procurement, storage, production or assembly referred to the numerous activities performed on the indicated assets and thus regarding the state and value of the goods, as well as the relations and subjects developed with them whereas on the other hand, each flow of goods is also connected with sufficient information that flows in the contrasting direction to the goods thus confirming the events that occurred (Sun, et al., 2008). These flows can be applied to check the movement of goods for instance on the basis of the punctuality of the supplier, the accuracy of the machines in the production stage or the reliability of a carrier (Ebrahimiarjestan & Wang, 2017). A flow of materials and information hence supplements flows of business correspondences, which are fundamental in the movement of materials and information. The relations between the firm and various third parties such as contractors and suppliers, who enter into operations with it, need definite, steadfast communications which can be initiated in different ways and with objectives that are variable. The communication flows system that is implemented by the firm is extensive, even for internal activities of the company, to achieve business goals such as beating deadlines, how to store and process goods, and accounting systems or to provide motivation for employees to adopt certain behaviour. Commercial external communication flows such as advertising and sales promotion are also rigorously influential to the simplification of goods movements since they are intended to assert the firm’s appearance and reputation on the market, and consequently motivate and put up with interest in demand with regards to competitors. Technological development, according to both Information and Communications (ICT) and manufacturing technologies has further broadened and made significant the potential for mutual support between flows of goods, information and communications. As a result of the vast possibilities for qualitative and quantitative increases in productivity and the reduction of costs firms have often focused considerable attention on manufacturing and handling of goods technologies (Ebrahimiarjestan & Wang, 2017). The use of digital technologies has proved effective in processes associated with flows of tangible materials, such as those associated with communication and information, thus allowing the creation of direct relations between flows which have always been entirely separate in terms of the possibility of detection and control, even though they are logically connected. For instance, traditional warehouse management now being replaced by digital technologies such as RFID which makes use of radiofrequencies to identify goods using distinguishing features such as size batch and deadline, or electronic manufacturing systems that may take over from humans in dangerous conditions but still be remotely controlled (Shields, et al., 2015). The other technology is electronic picking in warehouses and systems such as Vendor Managed Inventory (VMI) systems which allow suppliers to manage stocks of their personal goods on a customer’s warehouse by limited sharing of the database to control and augment supply flows (Gurenius & Wicander, 2007). The amount of tangible information flows generated by tangible assets, including the tools for managing them has been significantly increased by the development of the above mentioned technologies, thereby encouraging real-time controls of the physical processes and laying the foundation for the primary conditions for the organizational reaction typical of a pull approach to the market. This explains the reason why pull solutions of flows of tangible and intangible assets have become applicable alternatives for businesses, on one hand to replace and on the other hand to complement push solutions (Rodriguez, et al., 2007). This reflects how the supply chain management activities complement the application of AL. The significance of the decoupling point - the shift from a push strategy to a pull strategy - recognized together with the sound and chronological continuation of events along the supply chain, with regards to competitive opportunities and available resources, is evident in circumstances where goods flows are concerned. It also makes it possible to switch the decoupling point for intangible flows of communications and information in a more flexible way, where ICT technologies pave the way for the development of simultaneous push and pull solutions with regards to the market.

The major characteristic of digital flows of communications and information is the probability of directing two-way flows from the issuer to the receiver and vice versa.Infromation returning from the receiver, even in a very simplified form is foreseeable through any communication activity established using digital technologies, thus having a high value for corporate management with regards to monitoring the efficacy of any action taken (Danilo, 2017). This return of information propels the application of AL and the subsequent engagement of supply chain activities by different organizations particularly in the automotive manufacture, e-commerce, and clothing manufacture industries. Consequently, push strategies which have a one-way, binding linear flow of goods and information, together with pull strategies wherein the linear nature of information moves in the opposite direction to the flow of goods, but still remains one-way, are giving way to a varied system of associations between players, sustained by a freeinformation exchange, according to a circular model. The effect of applying IT to the management of flows of goods and information and business communication is the fact that it is now possible to apply supply chain management pull strategies where conventionally only AL-related push strategies could be applied (Danilo, 2017). Certain car makers after developing software known as ‘configurator,’ put it on the internet after giving it to their dealers. Through the software, a prospective buyer can choose a car by combining a range of alternatives such as the engine size and type, interior colours and materials, body colour among others and to instantly view the final price. The software gives the customer a chance to make the decision on the type of car he wants and allows the manufacturer to assess the most regular requests but also to manufacture the directly requested model where the inquiry results in an actual purchase (Hubaux, et al., 2012). The market is significantly affected by the combination of push and pulls factors thus affirming the efficacy of a firm’s proposals, but also within the firm or in the network of companies in the supply chain, since it improves the verification of internal and external efficacy.

The reaction the firm receives on one hand by adopting a pull strategy instantly shows the market response, making the identification of potential contexts for reiterated responses which allow push strategies to be adopted a possibility, or the desire to intensify pull solutions which are reactive and flexible whereas on the other hand, AL-related push strategies are conventionally related to the maximization of internal efficiency controls, the market response notwithstanding, a case in point being in the last century Japanese manufacturing firms in textile and automotive industries, which pioneered the combination of pull and pushstrategies to flows of goods, information and communication on a large scale, at first relating to their manufacturing processes, and then more broadly relating to suppliers and distributors (Toyota Motor Corporation, 2012).

Push and Pull strategies in Corporate Management