Soil Properties in Foundation Design

Introduction

Foundation design involves extensive calculations by the structural engineer to ensure the resultant structure is able to support the whole building. To achieve such a sound structure, the ground on which the foundation is to be built must be investigated for engineering properties such as shear strength, compressibility characteristics, permeability, compaction characteristics and tendency to swell or collapse. Depending on the characteristics of a given soil, the foundation can be built at a range of depths. The main factors that determine the depth of foundation are soil bearing capacity, soil type, groundwater table and minimum depth requirements. The bearing capacity of soil is the maximum allowable contact pressure between the soil and the foundation that will prevent shear failure. Three notable persons have proposed formulae for calculation of the bearing capacity of soils, namely: Karl von Terzaghi (1943), Meyerhof (1951, 1963), Brinch and Hansen (1970). For the purpose of this assignment, we will use the Terzaghi’s bearing capacity equation.

Continue your exploration of Psychological Theories in Lifespan Development with our related content.

Task

Carry out bearing capacity calculations for shallow foundations for the scheme,alongside calculations for deep and piled foundations, so that a comparison can be made of the relative dimensions of the shallow and piled foundation solutions.

Solution

Bearing Capacity calculations will be carried out for the following 4 sections

Development area 1 considering soil zone A

Development Area 2 falling under soil zone A

Development Area 2 falling under soil zone B

Development Area 3 falling under soil zone C

I – Development Area 1 falling under zone A

Specifications

Mixed retail development

Pad loads from portal frame buildings of between 400 kN and 600 kN

Perimeter Wall loads of between 40 kN/m run and 50 kN/m run

Part 1 - Pad foundation for the portal frame building

Assumptions

Maximum axial load of 600 kN

Ø=300

Cu=50kN/m2

d=17.8kN/m2

s=19.3kN/m2

Water table is at a depth of 3m from the ground level

Foundation sits at a depth of 2m in the region of firm clay

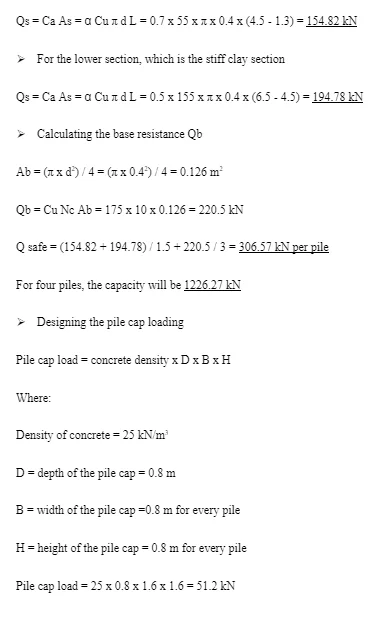

A) Calculate the shaft resistance Qs

For the upper section

The pile dimensions will first be assumed then their capacity to carry the provided loads assessed.

Total loading from building and pile cap = 600 + 51.2 kN = 651.2 kN < 1226.27 kN

Therefore, the proposed piles of length 10 m and diameter 0.4 m are adequate to carry the maximum load of 600 kN from the building.

B) Shallow foundation in the short term

The dimensions of the shallow foundation will first be assumed then their capacity to carry the provided loads assessed.

Net safe bearing capacity

Qns = (Qult - γD) / F + γ D = (429 - 20 x 2.5) / 3 + (20 x 2.5) = 176.33 kN/m2

176.33 x 2.5 x 2.5 = 1102.08 kN > 600 kN

Thus the provided dimensions for the foundation are adequate to carry the maximum loads projected

1. C) Shallow foundation in the long term

= (3 x 25.8 x 1.57) + (0.5 x 10.19 x 2.5 x 10.9 x 0.6) + (20 x 2.5 x 14.7 x 1.53) = 1329.37 kN/m2

Net safe bearing capacity

Qns = (Qult - γD) / F + γ D = (1329.37 - 20 x 2.5) / 3 + (20 x 2.5) = 476.46 kN/m2

This shows that the long term drained capacity 476.46 kN/m2 exceeds the short term undrained capacity 176.33 kN/m2 by far

II - Development Area 2 falling under Zone A

Specifications

Sports use with club house

6 storey hotel

5,000 capacity Sports stadia

Client has 2 provisional layouts for North and South areas

Column loads for hotel foundation exceed 800 kN, reaching a maximum of 2,500 kN

Part 1 - Pad foundation for hotel in North area

Assumptions

Square footing

Maximum axial load of 2500 kN

Ø=300

Cu=50kN/m2

d=17.8kN/m2

s=19.3kN/m2

Water level is at a depth of 3m from the ground level

Foundation sits at a depth of 2m in the region of firm clay

A) Determining the shaft resistance

B) Designing the pile cap load

Pile cap load = concrete density x D x B x H

Where:

Density of concrete = 25 kN/m3 D = depth of the pile cap = 1.2 m B = width of the pile cap =1.2 m for every pile H = height of the pile cap = 1.2 m for every pile Pile cap load = 25 x 1.2 x 2.4 x 2.4 = 172.8 kN

Adding the maximum load from the building to the weight of the pile cap, 2500 kN + 172.8 kN = 2672.8 kN < 3595.33 kN Therefore, 4 No. Piles, each 10 m long and 0.5 diameter can adequately carry the maximum hotel load of 2500 kN

2.C) Shallow foundation

Shallow foundation in the short term

Cu = 55 kN/m2 c’ = 3.0 kN/m2 γ = 20 kN/m3 ϕu = 00 B = 4 m L= 4 m D = 2.5 m D/B = 2.5 / 4 = 0.625 B/L = 4 / 4 = 1

From the Skempton’s design chart, Nc = 7.3

Ultimate bearing capacity

qn ult = Cu Nc = 55 x 7.3 = 401.5 kN/m2

Net safe bearing capacity

Qns = (Qult - γD) / F + γ D = (401.5 - 20 x 2.5) / 3 + (20 x 2.5) = 167.17 kN/m2

176.33 x 4 x 4 = 2674.67 kN > 2500 kN

The suggested foundation dimensions are good enough to carry the expected loads

Shallow foundation in the long term

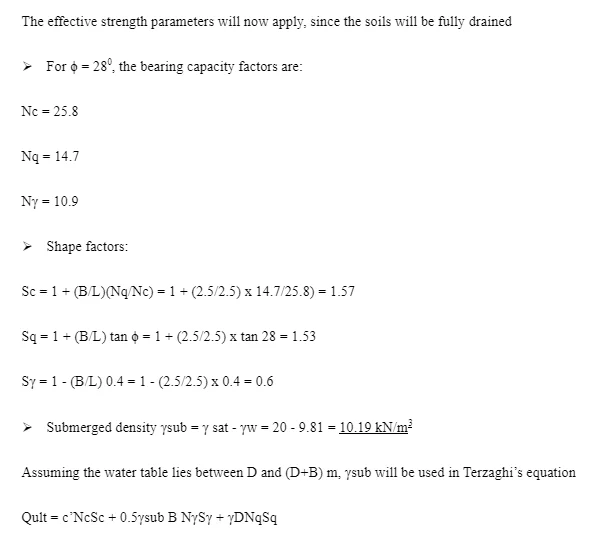

The effective strength parameters will now apply, since the soils will be fully drained

For ϕ = 280, the bearing capacity factors are:

Nc = 25.8

Nq = 14.7

Nγ = 10.9

Shape factors:

Sc = 1 + (B/L)(Nq/Nc) = 1 + (2.5/2.5) x 14.7/25.8) = 1.57

Sq = 1 + (B/L) tan ϕ = 1 + (2.5/2.5) x tan 28 = 1.53

Sγ = 1 - (B/L) 0.4 = 1 - (2.5/2.5) x 0.4 = 0.6

Submerged density γsub = γ sat - γw = 20 - 9.81 = 10.19 kN/m3

Assuming the water table lies between D and (D+B) m, γsub will be used in Terzaghi’s equation

Qult = c’NcSc + 0.5γsub B NγSγ + γDNqSq

= (3 x 25.8 x 1.57) + (0.5 x 10.19 x 4 x 10.9 x 0.6) + (20 x 2.5 x 14.7 x 1.53) = 1379.35 kN/m2

Net safe bearing capacity

Qns = (Qult - γD) / F + γ D = (1379.35 - 20 x 2.5) / 3 + (20 x 2.5) = 493.12 kN/m2

This shows that the long term drained capacity 493.12 kN/m2 exceeds the short term undrained capacity 167.17 kN/m2 by far

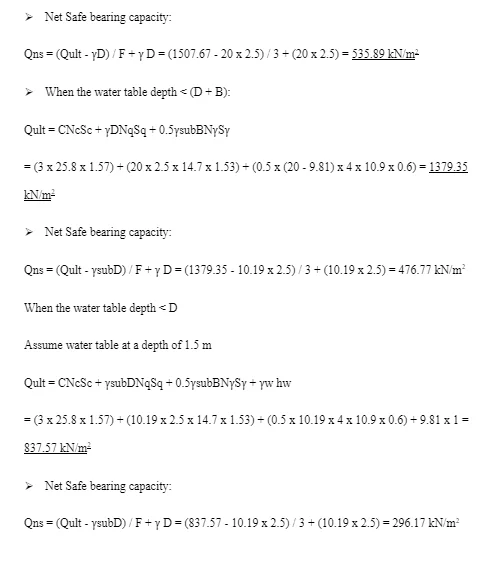

3.D) Investigating the effect of water table

When the Water table depth ≧ (B+D):

B = 4 m, D = 2.5 m

Qult = CNcSc + γDNqSq + 0.5γBNγSγ

= (3 x 25.8 x 1.57) + (20 x 2.5 x 14.7 x 1.53) + (0.5 x 20 x 4 x 10.9 x 0.6) = 1507.67 kN/m2

III - Development Area 2 falling under Zone B

Specifications

Sports use with club house 5,000 capacity Sports stadia 6 storey hotel Column loads for hotel foundation exceed 800 kN, reaching a maximum of 2,500 kN Client has 2 provisional layouts for North and South areas Part 2 - Pad foundation for hotel in South area

Assumptions

Square footing

Maximum axial load of 2500 kN

Ø=300 Cu = 60 - 65 kN/m2 d=17.8kN/m2 s=19.3kN/m2 Water level is at a depth of 4m from the ground level Foundation sits at a depth of 3m in the region of firm clay

4.A) Determining the shaft resistance

For the upper section,

Take a shaft diameter of 0.5 m

Qs = Ca As = α Cu π d L = 0.7 x 60 x π x 0.5 x (4.5 - 1.0) = 230.91 kN

For the lower section

Starting with the stiff clay section

Qs = Ca As = α Cu π d L = 0.5 x 150 x π x 0.5 x (13.5 - 4.5) = 1060.3 kN

Calculate the base resistance

Ab = (π x d2)/4 = (π x 0.52)/4 = 0.196 m2

Qb = Cu Nc Ab = 150 x 10 x 0.196 = 294.0 kN

Q safe = (230.91 + 1060.3) / 1.5 + 294.0 / 3 = 958.81 kN per pile

4 piles will be able to carry 4 x 958.81 = 3835.23 kN, which is adequate for the 2500 kN maximum load from the 6 storey hotel.

4.B) Designing the pile cap load

Pile cap load = concrete density x D x B x H

Where:

Density of concrete = 25 kN/m3

D = depth of the pile cap = 1.2 m

B = width of the pile cap =1.2 m for every pile

H = height of the pile cap = 1.2 m for every pile

Pile cap load = 25 x 1.2 x 2.4 x 2.4 = 172.8 kN

Adding the maximum load from the building to the weight of the pile cap,

2500 kN + 172.8 kN = 2672.8 kN < 3835.23 kN

Therefore, 4 No. Piles, each 10 m long and 0.5 diameter can adequately carry the maximum hotel load of 2500 kN

4.C) Consider a rectangular deep foundation

Qult = 0 + (22.4 x 5) + 0.5 x 20 x 3 x 3 x (1 - (0.2 x 3 / 3.5)) = 186.57 kN / m2

Calculating the bearing pressure q

Q = p / (LB) = 2500 / (4 x 3) = 208.33 kN/m2

187.57 kN/m2 < 208.33 kN/m2

The suggested dimensions for the foundation are enough to support the expected loads

IV - Development Area 3 falling under Zone C

Specifications

Low rise 2-3 storey residential housing estate Associated access and site infrastructure Perimeter wall loads between 30kN/m run and 40kN/m run

Assumptions

Firm clay is not present under this zone, therefore pile foundation would be most appropriate Assume 12 m prestressed concrete pile Assume 500 mm square piles Water table at a depth of 8 m Upper clay layer 8 m thick

For upper clay layer

=17.8kN/m2 Cu = 30 - 35 kN/m2

Lower Clay layer has

=20kN/m2 Cu=150kN/m2

4.A) Designing the pile

For the upper section,

Take a shaft diameter of 0.6 m

Qs = Ca As = α Cu π d L = 0.7 x 30 x π x 0.6 x (8.3 - 1.0) = 288.96 kN

For the lower section

Qs = Ca As = α Cu π d L = 0.5 x 150 x π x 0.6 x (16.5 - 4.5) = 1696.46 kN

Calculate the base resistance

Ab = (π x d2)/4 = (π x 0.62)/4 = 0.283 m2

Qb = Cu Nc Ab = 150 x 9 x 0.283 = 381.70 kN

Q safe = (288.96 + 1696.46) / 1.5 + 381.7 / 3 = 1450.85 kN per pile

4 piles will be able to carry 4 x 958.81 = 5803.4 kN, which is adequate for the 2500 kN maximum load from the 6 storey hotel.

4.B) Designing the pile cap load

Pile cap load = concrete density x D x B x H

Where:

Density of concrete = 25 kN/m3

D = depth of the pile cap = 1.2 m B = width of the pile cap =1.2 m for every pile H = height of the pile cap = 1.2 m for every pile

Pile cap load = 25 x 1.2 x 2.4 x 2.4 = 172.8 kN

Adding the maximum load from the building to the weight of the pile cap,

2500 kN + 172.8 kN = 2672.8 kN < 5803.4 kN

Therefore, 4 No. Piles, each 10 m long and 0.6 m diameter can adequately carry the maximum hotel load of 2500 kN

Task

Determine an appropriate arrangement of ground improvement techniques to deal with the need for ground raising on site above the soft alluvial deposits and hence provide recommendations on how to engineer the roads, services and drains so that they remain in a serviceable state (focus on the geotechnical processes occurring in the soft alluvial deposits and hence provide detailed calculations to support your solution to deal with any expected ground movements).

Solution

The soft alluvial deposits on a larger area of the scheme render its bearing capacity and settlement criteria inadequate for construction of roads and the corresponding drains. The soil strength has to be improved to pave way for the civil engineering structures. This is basically what ground improvement entails - modification of soil parameters. Below is an outline of ten of the most appropriate ground improvement techniques viable for the scheme:

Compaction - This method involves dynamically loading the soil so as to expel air from the voids in the soil and therefore make it more dense. This method can be used to improve the foundation of highways

Mechanical Stabilization - This will be helpful in areas of shallow depth. The method involves mixing the soil with inactive material such as aggregate or gravel, then compacting the mixture to the required density.

Improvement of soil by use of admixture - The engineering properties of the soil can also be enhanced by adding little amounts of admixtures such as lime, cement and bitumen. This method is particularly beneficial for shallow depths. Soil is first dug out, then the admixture is added and thoroughly mixed, and finally the mixture is compacted. This method is commonly used in the construction of roads. Recent technology has made it possible for the admixture to be added to the in situ soil without first excavating the soil

Use of geo-grids - This ground improvement method works by absorbing the stress and limiting the lateral movement of the soil. Geogrids have to be designed, and this involves determining the ultimate and serviceability limit states. Both live loads, dead loads and anticipated loads should be considered in the calculations. The use of geo-grids is especially common in construction of embankments for roads, construction of retaining walls, control of soil erosion and assisting drainage.

Dynamic compaction - This method involves heavily tamping the weak soil to strengthen it. A heavy hammer is raised high and dropped onto the ground with high energy. The energy employed in the tamping will vary with the location and specific condition of the soil. The high energy employed makes this method useful in areas where the improvement needs to be done to some substantial depth. This is more economical when compared to other ground improvement methods for deep foundations.

Preloading - The soft alluvial deposits in this scheme have very low bearing capacity and are highly compressible, and thus can lead to huge settlement. This can be countered by elevating the embankment and allow it to consolidate over some good time. This way the soil is kept under pressure. Once the consolidation process is over, the embankment can be removed and construction can begin.

Dewatering - This basically involves getting rid of water from voids so as to reduce the compressibility of the soil and increase the strength. Dewatering techniques include slump drain, prefabricated vertical drain, vertical sand drain and vacuum preloading. Given that the load comes from the weight of the embankment, consolidation settlement occurs due to changes in the volume of the soil and also shear stress induced deformations. In case vacuum pressure is applied, there will be only isotropic stress increasing in the soil. In this scenario, the ground below the embankment will be laterally displaced.

Vibro-replacement - This method involves installation of big columns of coarse backfill material in the soil by use of special depth vibrators. The resulting interconnection of stone columns and sandwiched soils provides a strong foundation support system with reduced compressibility and increased bearing capacity. This method is suitable for the soft alluvial deposits present in this scheme. On top of improving the strength and deformation properties of the soil, the stone columns make the soil more dense while in situ, as well as drains the resulting pore water pressure. This works to reduce the post construction settlement.

Jet Grouting - This method involves drilling some string up to an appropriate depth, then filling the void with grout or high pressure water. The grout is able to mix with the soil due to the erosive action of the water/grout.

Deep cement mixing - This ground improvement method involves the formation of soil-cement columns in-situ. , by injecting either cement powder or cement slurry into the soil under great pressure. This is made possible by use of rotary machines with high torque capacity. The cement is progressively infused into the soil and manually mixed with the soil particles by the help of special tools fixed to the rotary device. The cement particles react chemically with the soil particles in the process known as hydration, resulting into a hard material which is more stiff and has higher strength than the original soil layer. This method can be appropriately applied for foundations beneath embankments, stabilization of the base of excavations, and also construction of retaining walls. In places with loose sand, this method can also be applied to prevent liquefaction.

Task

Outline the technical and practical problems likely to be experienced when implementing the solution to the ground problems at the given site.

Solution

In the course of the ground improvement techniques mentioned above, there are a number of challenges normally encountered, owing to the poor soil conditions. Clay soils are known to be lumpy and sticky when wet, rock-hard when dry, have poor drainage and very few airspaces. These are the characteristics that cause the challenges outlined below:

Soft clay can lead to great settlement when under a big load. This can be attributed to the poor drainage characteristics of clay soil. The pore pressures existing in the midst of the clay particles take a lot of time to migrate and therefore causes long term consolidation settlement.

Clays are known to swell or shrink when the moisture content changes. Shrinking can lead to considerable subsidence of foundations. Swelling on the other hand can cause soil heave, where the soil pushes the foundation, and therefore the whole structure, upwards.

Some types of clay are greatly sensitive and can experience a quick loss of shear strength when disturbed. Clay sensitivity is basically the ratio of the original shear strength to the remolded residual shear strength. The same is also known to change engineering properties when subjected to stress beyond some certain limit. This clay also exhibits reduced remolded strength - this is the amount of residual shear strength as obtained in a direct vane test after the very first shear. Normal clays have sensitivities of about 1-3 but some clays exhibit sensitivities of up to 20.

Clays have a very great challenge regarding settlement. In the construction of roads, embankments fills and area grade raise fill are common. Loading clays with such fills is known to create settlement, as well as problems with scheduling.

The scheme described in the course work has man made fill soil on all the zones, with thickness ranging from 0.5 m to 4.3 m. Such man made ground normally does not show consistent engineering characteristics. Man made fills are also heterogeneous in nature and can be contaminated. Performing ground improvement in the presence of such soils is challenging in the following ways:

Grounds with man made infills are normally challenging to develop. They may require large scale excavation and disposal, which ends up escalating the project costs.

Undocumented fill varies greatly in characteristics and therefore it becomes difficult to determine the particular parameters that should be considered when it comes to improving the soil. Such soils are best excavated and re-engineered or substituted with approved engineered fills.

Hydraulic fills are as a result of water action. This results to multi-layered soils mixed with deleterious and organic materials. The compressibility of such soils likewise varies spatially, and thus implementation of ground improvement techniques becomes difficult.

Conclusion

Shallow foundations are normally adopted when the structural load is considerably less and the soil is dense. Shallow foundation refers to those whose depth is less than or equal to the width of the foundation. Pile foundations on the other hand are adopted when the structural load is considerably heavy and the soil is weak. In general, pile foundations are categorized under deep foundations, where the depth is greater than the width of the foundation.

References

Arya, C. (n.d.). Design of structural elements.

Bearing capacity of soils. (2004). Honolulu, HI: University Press of the Pacific.

Hansbo, S. (1994). Foundation Engineering. Oxford: Elsevier Science.

Holtz, R., Kovacs, W. and Sheahan, T. (2011). An introduction to geotechnical engineering. Upper Saddle River, NJ: Pearson.

Schaefer, V. and Abramson, L. (1997). Ground improvement, ground reinforcement, ground treatment: developments 1987-1997. New York, NY: American Society of Civil Engineers.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts