Advancements in Self-Reinforced Polypropylene Composites

Abstract

Self-reinforced polymer composites (SRC), with a highly oriented thermoplastic reinforcement and a matrix with less degree of crystallinity–from the same or similar polymer family - have been introduced to mitigate some of the drawbacks of widely-used conventional composites, such as recyclability and ease of manufacture. SRCs are fully recyclable due to the same chemical structure of its constituents, which also ensures a strong interfacial bond between the fibre and the matrix. Self-reinforced polypropylene is one of the most common SRCs, available in the market. Self-reinforced polypropylene (SRPP) materials are used for energy-absorbing applications due to their high ductility and impact resistance. The main aim of the current work is to investigate self-reinforced polypropylene materials and their response under impact events. Understanding the processing and testing parameters that affect the properties, improve the performance of SRPP and their reparability are the main objectives of the work. Additionally, for those needing assistance with complex analysis, engineering dissertation help can provide valuable support in this area.

Manufacturing parameters change the final properties of SRPP composites. The thermoplastic reinforcements in SRCs are unstable, as they are highly oriented. Therefore, high temperature and low pressure change their oriented configuration, leading to a change in the thermal and mechanical properties of the consolidated laminates. Consequently, it is vital to understand and optimise the manufacturing of SRPP composites. Consolidation temperature and pressure, cooling rate, and compaction time were identified as the main influential parameters. The first two were primary and dramatically affected the mechanical properties, while the latter two were secondary parameters. The properties of the consolidated laminates did not change significantly within the processing window (125°C-150°C). It was also found that, minimum pressure of 50 bars is required to prevent unwanted shrinkage with the highest value at 70 bar pressure. Impact resistance of the laminates was found to decrease by increasing the consolidation temperature, which is linked to a higher degree of interlayer delaminating at lower consolidation temperatures.

SRPP materials, even at the optimised processing conditions, had low stiffness, which constraint their application. Hybridising SRPP with a stiffer reinforcement was pursued to overcome the toughness-stiffness dilemma and resulted in novel hybrid composites with high stiffness, ductility and strain to failure. Glass fibre was hybridised with SRPP for stiffness enhancement without curtailing the ductility and exhibiting progressive failure. Glass fibre volume fraction and its thickness and the layup were the crucial design parameters to reach pseudo-ductility and progressive failure. By keeping the glass fibre volume fraction below 6.5% pseudo-ductility was achieved. Furthermore, the dispersed layups (were the glass fibre layers were dispersed between the SRPP fabrics) worked in favour of increasing the maximum glass fibre and still having the progressive failure. Other properties such as fibre/matrix adhesion and the mechanical properties of the SRPP are also defined as further requirements to have the optimised hybrid. The interlayer delaminating of the interfaces worked in favour of the energy-absorbing mechanisms. Therefore, despite adding a more brittle reinforcement system, the impact resistance remained the same, and in some cases improved.

Delaminating of the layers in low impact energy could be repaired through different composite repair techniques. Re-thermoforming and patch repair was tried for different layups of the SRPP and their hybrids with glass fibre. Through the repair procedure, some layups retained their original stiffness and strength completely while others could be repaired up to 50%.

Finally, a road map was set for optimising self-reinforced polypropylene composites and potential benefits of using hybrids were discussed. The reparability of SRPP and their hybrids was attempted for the first time and was very promising due to the possibility of repairing a damaged part in service.

1 Introduction

1.1 General Introduction

Fiber-reinforced polymer composites are a group of materials made of at least two constituents; the reinforcement and the matrix. The reinforcement can be continuous or discontinuous. In a composite part, reinforcements are responsible for stiffness and strength of the part, but they need the polymer matrix to make an integrated, single part. Therefore, the polymer matrix issued to bind the reinforcements together and consolidate the structure. Carbon, glass, and Kevlar fibres are the conventional reinforcements with high demand and applications. The low-density polymer matrix integrates the reinforcement and fulfils the objective of high mechanical properties and low weight.

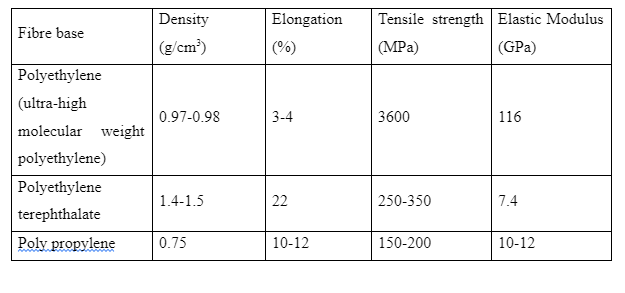

Different choices of the reinforcement and matrix materials, composites have a growing number of applications as they can be tailored for the specific requirements [1]. Table 1summarises the properties of the selected reinforcements used the most. As seen, high strength/ stiffness fibres suffer from low elongation, which can limit their applications. To address the drawback, another group of reinforcements have been introduced to the market with thermoplastic nature. Thermoplastic reinforcements are made by stretching the thermoplastic polymer and reorienting the polymer backbone. The process increases the stiffness and strength of the fibre. Table 2 shows the properties of some of the common thermoplastic reinforcements. As seen, thermoplastic reinforcements have higher elongation and lower density, which impart to composite parts with higher specific properties and ductility.

The other constituent in a composite is the matrix. The polymer matrix can be thermoset or thermoplastic. Thermoplastic composites have shorter cycle time, which in favour of large scale manufacturing, and they provide higher impact resistance than their thermoset counterparts [2][3]. On the other hand, the molten thermoplastic matrix has a high viscosity, which makes impregnation difficult, and high temperature is needed to melt the thermoplastic matrix[4][5]. In a broader perspective, even thermoplastic polymer matrix composites with the conventional fibre reinforcement are accounted as a brittle material. Therefore, combining the thermoplastic matrix and thermoplastic reinforcements may lead to promising results.

Self-reinforced composites (SRC) are a group of fully thermoplastic composites with thermoplastic matrix and reinforcement with the same or similar polymer family. They are recyclable and the same chemical structure of the constituents ensures strong fibre/ matrix interfacial strength. If the matrix is in-situ around the thermoplastic fibre, the impregnation issue can also be addressed. Self-reinforced polypropylene are not only the toughest self-reinforced materials and show excellent ductility, but it exhibits high failure strength and are the most important SRC in the market [9][10][11].

Dig deeper into A Journey of Survival, Discovery, and a New Beginning with our selection of articles.

1.2 Problem Statement

Self-reinforced polypropylene materials have great impact resistance with high ductility and failure strain but they suffer from relatively low stiffness and strength [12][13]. On the other hand, the conventional composites fulfil the requirement of high stiffness/strength, but they behave as a brittle material and suffer from low ductility and failure strain [14]. Toughening matrix by adding thermoplastic particles [15]. Another approach to introduce novel properties to composite structure and to overcome the stiffness/toughness challenge is hybridisation. Hybridising two or more fibre reinforcements in a single matrix is a technique to tailor properties, and hybridisation of a ductile reinforcement with a brittle where one can pursue this objective.

Continue your journey with our comprehensive guide to Blast Furnace Production.

Great research has been completed on hybridising two brittle reinforcement in a single matrix. Carbon/glass epoxy hybrid composites are the most common hybrid composites [16][17][18]. Other attempts have been made in hybridisation of brittle/ductile reinforcements [19][20] in which carbon fibre has been hybridised with self-reinforced polypropylene. The work on SRPP and carbon shed a new light of capabilities of both constituents. Still, the significant difference between carbon and self-reinforced polypropylene made progressive failure almost un-reachable. Glass reinforcement is the other alternative with properties that can pursue progressive failure with enhanced properties and the response is not fully explored. Understanding the failure mechanism of hybrids is a challenging tasks and needs investigation of the all variables in composite design and test parameters. Data lacks on defining the governing factors responsible for the response of hybrid composites.

Furthermore, processing SRCs is challenging as they are sensitive to heat and pressure due to the stretched and oriented thermoplastic reinforcement [21]. Another note to mention is that, melting and processing conditions change with chemical structure of the constituents. Therefore, processing conditions need to be monitored to reach the optimum properties. Adding the second reinforcement can also alter with the processing parameters.

Once composites are damaged, they lose their properties to some degree. The extent of damage and energy dissipation in the composite defines the severity of the damage. In limited damaged composites, the repair is an option to bring the part to service. Minimal studies (if any) have explored the repairability of SRCs and their hybrids, and the literature lacks data in this field. Understanding damage and repairability is a demanding area and can cut-off costs in composite usage and needs further study.

1.3Aims and Objectives

The main aim of the current work is to investigate the crashworthiness of self-reinforced polypropylene composites and improve their properties. Crashworthiness and impact resistance of self-reinforced composites is affected by testing and processing parameters. In order to ideally pursue this aim, there are objectives to be achieved:

Understanding the optimum processing parameters is effective to manufacture self-reinforced polypropylene composites. This is achieved by studying the effect of each parameter on mechanical properties such as tensile and impact resistance of SRPP materials.

Improving the performance of self-reinforced polypropylene composites by hybridisation with glass fibre reinforcement. Hybridisation provides the opportunity to have higher mechanical properties for SRPP, which is appealing. However, to retain the progressive failure, high failure elongation, high ductility and impact resistance, it is crucial to explore the failure mechanism of the SRPP/glass reinforced polypropylene hybrids and deepen the knowledge around interactions of the constituents and approaches toward tailored properties.

Investigation of the repairability both in SRPP and their hybrids. This objective is fulfilled by understanding the damage mechanism and the failure response of thermoplastic polypropylene and brittle glass fibres, as well as the role of the damage and the introduced impact to the composite part. Moreover, a thorough study needs to be completed on the remained properties after damage and retained properties after repair.

1.4 Outline of the thesis

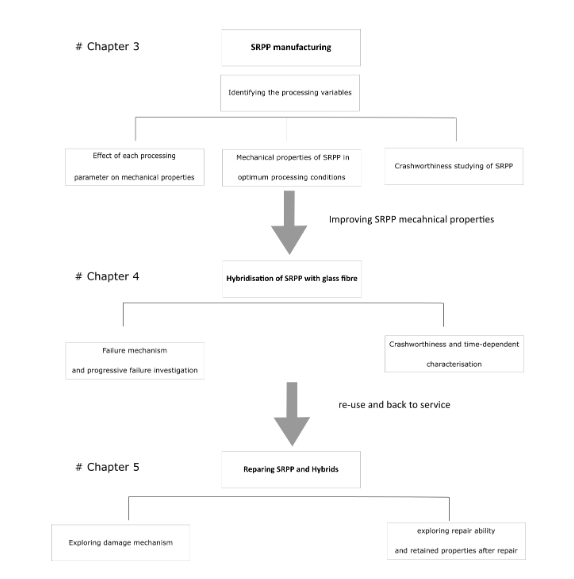

For successfully achieving the objectives of the project and covering the main aim of the work, this thesis is divided into three main experimental chapters with distinctive objectives. The structure of the work is as presented in Figure 1. Referring to the objectives pointed out, each experimental part is design to answer one of the objectives of the work.

Chapter 3 is the first technical chapter, which investigates the processing parameters affecting the behaviour and mechanical properties of SRPP. Thermal characterisation techniques used to understand the melting of the constituents and the onset of melting to start consolidation. In this chapter, processing variables were justified by their effects on the final mechanical properties of the consolidated laminates and the effect on the crashworthiness of impact resistance of SRPP. Finally, it was attempted to draw a more unite trend between the consolidation temperature (as the primary processing variable) and the stiffness of the SRPP laminates. The introduced technique can be used a guide in manufacturing SRPP laminates.

Chapter 4 is the also effective to review performance improvement of SRPP laminates that has been investigated. In this chapter, interplyhybridisation of SRPP materials with higher stiffness/strength reinforcement such as glass fibre was explored. It has been shown that, hybridisation improves the stiffness of the SRPP composites, but the need to remain the progressive failure is crucial. Therefore, factors alter the pseudo-ductility of the hybrids were studied and reported. It was tried to represent a comprehensive failure mechanism of interplay hybrids.

And in chapter 5, the repairability of the SRPP and their interplay hybrids with glass reinforcement was investigated. The effect of impact energy, as well as layup, was studied for better understanding regarding the damage propagation and specimens that were repaired and their mechanical properties were measured after impact and after repair to evaluate the effect of layup, impact energy and matrix modification on the effectiveness of the impact.

In the end, all results are summarised and linked together to draw a map for better understanding self-reinforced polypropylene materials and their behaviour under different processing conditions, damage propagation, hybrid failure, and crashwothiness.

Overall Discussion and Conclusion

The overall research objective was to understand the performance of SRCs under impact and optimise the mechanical performance of SRCs. This was pursued in three main work packages in this study: Optimisation, hybridisation and repair. Results of each work package were reported in a separate chapter, leading to three main technical chapters in total. An overall discussion was made over each part of the work as follow to draw the road map of the work.

Work package 1; Process Optimisation, Chapter 3

In the first step, the manufacturing process was optimised with refer to the final mechanical and impact properties of the laminates. It was crucial to assure the consolidation quality to have a full picture of SRPP capabilities and how and to what extent can process affect the performance.

Self-reinforced polypropylene materials are known for their high ductility and impact resistance with respect to the low density of the PP fibres. However, it is important to understand what variables affect their impact resistance. In order to understand the optimum parameters to consolidate SRPP composites, influential variables were identified, and their effect on mechanical properties was studied. The two more dominant variables were temperature and pressure (section 3.1). This was due to the highly drawn nature of the PP fibres and their sensitivity to elevated temperatures and pressure. At high temperature and in lack of enough pressure, the drawn polypropylene chains shrink. This was reflected when consolidation attempted with hot rollers (section 3.2.2) in high temperature but a short period being under pressure. So, it was found to be paramount to keep pressure along with the process. Not only the presence of the pressure was necessary, but the study confirmed that the higher pressure leads to higher stiffness and strength. This finding was predictable though, as the highly unstable fibres shrink and the lamellar structure deform as well the tie molecules between the lamellar and resulted in mechanical properties decrease (Figure 3.7). Temperature of consolidation is another factor, which is dictated from the constituent’s chemical characterisations as both the reinforcement and the fibres have thermoplastic nature. The process temperature window for each SRPP materials can be approximated from the thermal analysis of materials (Figure3.1). Temperature was found to have the highest effect, when it started melting the core fibres. By melting the crystalline structure of the fibres even under high pressure of 70 MPa, laminates lost their stiffness up to 100% at a temperature above the melting point of the fibres.

Two other factors, holding time and cooling rate, were also studied. They found to have little effect on the performance, but the main findings emphasised that, holding time and process temperature have the same effects while the holding time is less sensitive, as it is believed to affect mainly the tie molecule relaxation, if the temperature is held within the processing window (Figure 3.11). And, the cooling rate had minimal effect on the mechanical performance even though apparent differences were evident from the thermal analysis (Figure 3.13). This was explained by the weave pattern and the direction of crystal formation which was all around the fibres and therefore could not contribute to the total stiffness and strength.

Impact resistance of SRPP materials were also investigated first by mapping the energy profile. This step was necessary to identify a general perspective of the material behaviour under impact. By deriving the impact energy profile, the threshold zone between the non-penetrative damage and perforation area was measured. The non-penetrative region used to study the repairability of the SRPP and hybrids and the perforation impact energy was used to identify the effects of consolidation temperature on impact response. The main point was that, poor consolidation increased the absorbed energy by the SRPP specimen, but as poor consolidation had no preference in manufacturing point of view, it was not considered further. The perforation behaviour studied was further used for comparing study in the hybrids.

Work package 2; Hybridisation, Chapter 4

Once the behaviour and the mechanical performance were understood thoroughly, improving the stiffness and strength of the SRPP was investigated in the second work package. This part was with the aim of stiffness/strength enhancement while maintaining the high ductility of SRPP materials with minimum reduction of the failure strain.

Hybridisation of SRPP with glass fibre was performed in ply by ply configuration. Hybridisation was performed to improve the performance of SRPP materials, but in a manner that the failure of glass is captured by the surrounding SRPP fibres. Therefore, the first approach was to achieve progressive failure in the hybrids. Thus, the upper limit for glass fibre volume fraction to behave as a pseudo-ductile composite was studied (Figure 4.14). The hybrid effect was observed in the failure strain of the glass layer which was increased compared to when tested out of hybrid. The hybrid effect and the trend confirmed increasing the glass fibre volume fraction resulted in decreasing the hybrid effect (Figure 4.16). Above 6.5% glass fibre volume fraction, hybrid laminates’ response diverted from pseudo-ductility. This was attributed to the energy released after the glass fibre fracture, which is defined with the thickness of the glass fibre layer and its stiffness /strength.

The critical mode II fracture toughness of the glass layer therefore was predicted by approximating the energy released upon the failure of the glass reinforcement. This led to prediction of the hybrid laminate response. A more accurate method was to measure the GIIC directly and out of the hybrid at the interface of the glass and SRPP, but this technique was out of scope of this work, due to the lack of any standard procedure for measuring this parameter in bi-material interface. Following the simplified models on load distribution in an iso-strain specimen during tension, the failure strain of the glass layer and the final composite were also predicted.

The effect of layup was also investigated. This was performed by comparing the response in block and interleaved layup and the results revealed a shift of critical upper bound for glass fibre volume fraction to 10% when the layup is substituted with an interleaved one (Figure 4.22).

Adding glass fibre to SRPP was not preferable in impact resistance. This is due to the brittle glass fibre, which decreases the impact performance upon addition to the hybrid structure. On the other hand, in a hybrid specimen, a great portion of the impact energy is dissipated between the dissimilar layers. This was also reflected in the impact load-displacement curves of the hybrids (Figure 4.28). Therefore, the key to maintaining the ductility of SRPP laminates is in adopting higher stiffness glass laminates for improved impact resistance (Figure 4.29). Thus, between the two glasses fibres used for this study, the one with higher stiffness performed better in impact. On the other hand, with stronger glass fibre, reaching pseudo-ductility would be more challenging and finding a balance, which is crucial.

The impact resistance investigation of the hybrid laminates could be further improved by two means:

Testing the interleaved hybrid laminates under impact. This could provide more details on the effect of increasing the number of faces between different layers (SRPP and glass) and the extend of effect could be measured for design purposes.

As explained, delamination growth and energy dissipation between the layers is a key factor in hybrid laminates to absorb more energy upon the event of impact. In this case, performing the impact test on the hybrid laminates with low adhesion matrix may facilitate the delamination growth and energy absorption.

The second assumption was tried in the next chapter, in studying the repairability of the laminates after impact.

In the second work package, the stiffness was enhanced through hybridisation, while having a progressive failure. This was a success to reach the balance while not decreasing the impact resistance of the SRPP materials upon hybridisation.

Work package 3; Repair, Chapter 5

In the first work package, impact resistance of SRPP laminates were explored at different impact energies. Based on the impact energy and the absorbed energy, it was possible to define the non-penetration and penetration zone. The penetration study was completed to measure the maximum energy absorbing capability of SRPP materials. However, not all the impact events occur above the perforation zone, and in low energy impacts, laminates may not show any visible damage. Low energy impacts and limited damage extent give opportunity to repair the part. Repairability of the SRPP and hybrid laminates were investigated in the chapter 5.

The impact energies were decided, based on the energy profile of SRPP (Figure 5.2). However, the maximum energy was reduced for the hybrid sample, where the glass layer was in the outer surfaces as they behave in brittle manner.

Investigating the impact response showed that low adhesion matrix hybrids had less severe damage. The optical pictures of the impacted surfaces confirmed larger delaminated area for the hybrid laminates with glass in the mid-plane (Figure 5.7). Therefore, it was also predicted that, these hybrids perform better in repair. The main and most important finding was that, the stiffness of the repaired specimens was regained less, compared to the strength of the laminates. This was more evident that, when the SRPP layers were on both faces and due to the failure mechanism of the fibres through splitting and debonding, regaining the fibre orientation and fibre alignment in the repair process was more challenging (Figure 5.11). While, as the strength of the specimen is defined by the integrity of the part and load transfer between the fibre and the matrix and therefore, re-melting the matrix to integrate the laminate and fill delaminations could recover the strength of the part to a greater extent.

Adopting hybrid laminates with low adhesion matrix improved the repair quality (Figures 5.12 and 5.14). While the hybrids with low adhesion matrix had lower stiffness and modulus compared to those with strong fibre/matrix interface, the repaired parts showed the approximately same mechanical performance.

Repair efficiency of the specimens were tested in flexural while many works recommend compression after impact (CAI) for this purpose. The CAI test is useful to demonstrate how delaminations open upon compression. This test technique was not applicable for the material of study in this work. First, polypropylene has very high ductility and buckles under compression. Furthermore, the thickness of the laminates (less than 1.5 mm) made the compression test even more challenging and the derived data were not reliable as a result.

The technique could be improved further by performing a free drop impact test, where the specimens are not clamped in order to let the specimen to develop delaminated areas freely. Another approach was to trace the damage part using a c-scanner to capture the delamination growth and damage. However, due to the low thickness of the specimens and the developed dent at the sample surface, the common c-scanning probes could not made a successful scan through the specimen thickness. For this purpose, special probes were needed to submerge the whole sample to take through the thickness scan.

Conclusions

It is impossible to have a composite with optimal performance in all applications. All materials, including composites have advantages and drawbacks based on what they are adopted for. Process optimisation and performance improvement were the main objectives of this work. From investigations and studies performed in the work resulted in forming a guideline for performance optimising of the SRPP materials based on the applications. Table 6.1 summarises the findings. As seen, it is important first to define the application of the materials and tailor the design parameters with this regard as certain properties can conflict with each other in many cases.

As each application has different property requirements, the variables relating to them may be conflicting with each other. For instance, low adhesion matrix hybrid laminates were found to have higher impact resistance, while the same hybrids did not perform as well as high adhesion matrix laminates in flexural. Another example was the layup. In configurations with GRPP layers at both faces, flexural properties were improved. However, the same laminates were the optimum layup for repairability. Therefore, it is paramount first to define the requirements needs to be fulfilled by composite part in order to select the best variables to pursue the required performance.

Main Achievements and Impact

Process optimisation of self-reinforced polypropylene composites was investigated. The processing variables affecting the mechanical properties were also investigated and their effect on tensile, interlayer bonding strength and energy absorbing capability of the laminates were evaluated. The process optimisation led to defining optimum conditions for processing SRPP fabrics to have the optimum impact resistance and mechanical properties.

The stiffness of the woven SRPP laminates was predicted from the stiffness change in the unidirectional laminates. This method gives the opportunity to adopt the trend of stiffness with compaction temperature and apply it to another self-reinforced polypropylene material. The method used can reduce number of testing and it also can give an approximation on the stiffness of the consolidated laminate at different consolidation temperatures.

Hybrid laminates were developed with ductile SRPP materials and more brittle glass-reinforced polypropylene. The hybrid laminates gave a combination of enhanced stiffness and glass failure strain, as well as maintaining the impact resistance of the SRPP.

The correct choice of glass fibre volume fraction resulted in hybrid laminates with progressive failure. By investigating the damage mechanism of hybrid laminates, it was shown that they can be controlled in a way to behave as a pseudo-ductile material. Layup configuration, the properties of glass fibre reinforcement, and the volume fraction of the brittle reinforcement were studied as the effective variables.

The tensile behaviour of the interplay hybrid laminates were predicted from the fracture mechanics and from the strain energy release at the interface.

Impact resistance of the hybrid laminates were investigated and it was shown that achieving a hybrid laminates which perform as resistant as the SRPP under impact is possible. This was pursued by energy dissipation at the interfaces.

The importance of inter and interlayer bonding was also investigated in the impact, tensile and flexural performance. This has been also shown in Table 6.1.

Repairability of self-rely reinforced polypropylene composites and their interplay hybrids with glass reinforcement was explored. It was shown that the damage

Mechanism plays a primary role in repairability and regaining the properties of the laminate.

Further improvement and future work

The field of self-reinforced composites and their process optimisation has been well-established. Most of the recent works have been focused on developing new SRCs with other thermoplastic polymers. Few works have also been completed on adding nano-particles to SRCs to improve their performance. The latter can be further enhanced by introducing some level of heat conduction to the SRC fabrics to increase the maximum allowable thickness for hot compaction and to achieve uniform consolidation quality through the thickness.

In the field of hybrid composites, very limited works have been performed on adding glass reinforcement as semi-brittle fibre to self-reinforced polypropylene. The work performed here covered the main influential variables dominating hybrid behaviour and their failure mechanisms. The ideal hybrid composite is the one, which can improve the stiffness while retaining the progressive failure and high ductility of the ductile reinforcement. As investigated in the current work, the thickness of the brittle reinforcement has a paramount role in the released strain energy after its failure and thinner laminates performed better in progressive failure. The same work therefore, can be conducted working with thin plies such as spread tow glass fibres. Unfortunately, this item was not available at the time of this research work.

In the repair part, the work studied the re-compaction of the laminates in the same pressure and consolidation temperature as the initial processing. This part of the work could be improved by introducing other repair techniques such as patch-repair and optimising the repair process. Investigating the extent of the damage in the non-penetration zone could also be investigated more deeply by light transmission scanning.

Looking for further insights on A Journey of Survival, Discovery, and a New Beginning? Click here.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts